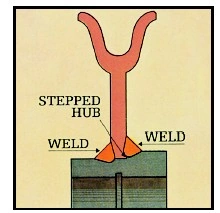

Stepped hub design proves better.

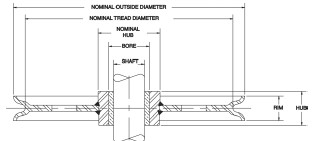

The McKissick hub is stepped to eliminate stress failure in the weld, common in traditional hub designs. The hub is pressed into place with complete metal-to-metal contact. This helps ensure an accurate alignment to the hubs axis so theres no wobble or lopping of the rotating sheave.

The precision aligned hub/sheave wheel combination adds to the bearing life and keeps the sheave on the job longer.

Closed die upset and roll forged not split.

Upsetting and roll forging forms the groove and flange walls in multiple steps, eliminating the need to split and weaken the groove. This exclusive forging process adds extra strength to the critical groove section. You can count on a McKissick sheave to give maximum life performance, because its forged to distribute the wire rope forces evenly over an accurately formed load surface. Plus, uniformity of the roll forged groove adds longer wire rope life.

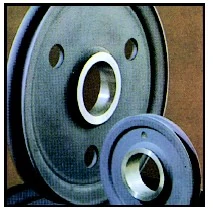

Full range of standard sheave sizes.

Solid steel no casting.

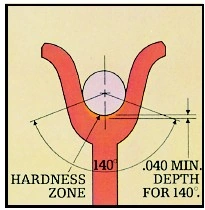

Flame hardened groove.

Crosbys hardening technique is a science. It provides a precise maximum hardness for wear-

resistance across the wire rope contact area. The McKissick sheave groove is flame hardened to a minimum 35 Rockwell C for a 140, contact area with the wire rope. The solid steel plate provides the ideal surface for flame hardening and a closer tolerance fit to the wire rope to reduce fatigue and wear.

Bearing selection to match your job requirement.

The McKissick Roll Forged sheave is available in the following configurations:

- Plain bore

- Bronze bushed

- Roller bearing

- Tapered roller bearing

- Lubrication thru hub

- Key ways

- Set screws

Ordering Information

McKissick sheaves come in a variety of sizes to suit your specific applications. Check the tables for the size, bearing style and price that best fits your application. For applications that require unique specifications Crosby can make minor modifications to many of the sheaves listed at a reasonable charge. We can also custom design and manufacture sheaves to your exact requirements. Contact Crosby Sales to order McKissick sheaves and include the stock number and quantity. For special requirements or custom designed sheaves, furnish the following important information:

|

|

Roll Forged Sheave Features

- Unique upset roll forging process provides a thicker groove section for extra strength.

- Stepped Hubs are precisely centered and mechanically locked in place.

- Wireline grooves on sheave diameters of 14" and larger are flamed hardened for extra wear resistance.

- All sheaves have solid steel webs with holes for easy handling.

- Sheave weights can be made heavier or lighter than shown to fit your specific application.

- For more information ask for our special brochure describing the complete roll forging process.

Sheave Bearing Application Information

Bronze Bushing -

Slow line speed, moderate load and moderate use,

Maximum Bearing Pressure (BP): 4500 PSI

Maximum Velocity at Bearing (BV): 1200 FPM

Maximum Pressure Velocity Factor (PV): 55000

| Formula for BP = |

Line Pull x Angle Factor (See Page 335) |

|

|

|

| Shaft Size x Hub Width (See example). |

Plain Bore-

Very slow line speed, very infrequent use, low load.

Faster line speeds, more frequent use, greater load.