-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Lifting Slings and Components

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Runway Beam Monorail Crane Trolleys, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms and Jib Cranes

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

- Man-riding Hoists & Rescue Winches

-

Fall Arrest & Man-riding Systems

- Fall Arrest Davit Arms & Posts for Working at Height

- Sala Advanced Davit Arm Systems and Components

- Xtirpa Confined Space Davit Arm Systems and Components

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding & Rescue Tripods & Quadpods

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

- Home/

- Lifting Equipment/

- Wire Rope Pulling Winches & Lifting Hoists/

- Cable Pullers / Hoists, Wire Rope Manual Operation/

- Yale Manual Wire Rope Cable Pullers and Hoists/

- Yale YaleTrac 'Y' Series Cable Puller Wire Rope Hoist for Lifting and Pulling Applications - Range from 800kg to 3200kg (Lifting Capacity)

Yale YaleTrac 'Y' Series Cable Puller Wire Rope Hoist for Lifting and Pulling Applications - Range from 800kg to 3200kg (Lifting Capacity)

Cable Pulling Machine Y08, Y16 and Y32. A Quality Yale alternative to the Tractel versions.

YaleTrac Y08, Y16 and Y32 / CPM-175

0.8 tonne, 1.6 tonnes or 3.2 ton Lifting Capacity

All Rope are fused and tapered at one end. The other end is terminated with a Crosby eye hook in heart shaped thimble secured by a mechanical splice.

This product is an alternative to the Tirfor product which we also offer.

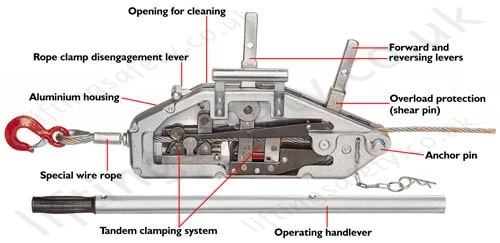

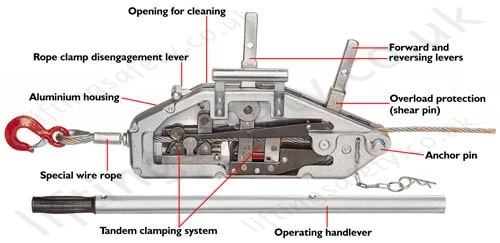

Yaletrac® cable pullers feature a lightweight, compact, high strength aluminium housing, smooth contour design with a large, flat bottom surface for increased stability in horizontal and vertical working positions.

Forward and reversing levers in tandem provide slim design and assure power transfer along the centre line.

Overload protection is by a shearing pin in the foward lever. Spare shear pins are conveniently located in the carrying handle or operating lever. A broken pin can be replaced without removing the load.

- A lever disengages the rope clamp system allowing easy, smooth installation of the wire rope.

- Yaletrac® uses a special flexible wire rope. It has six strands with a steel core.

- The rope is tapered at one end for easy threading and fitted with a safety hook on the other end.

- The parallel arrangement of the clamping system protects the wire rope by distributing the clamping forces evenly.

- A long rope advance per each lever stroke increases the working speed.

- The large opening in the top of the unit allows easy cleaning: simply flush the unit with water, apply motor oil for lubrication and the Yaletrac is again ready for use.

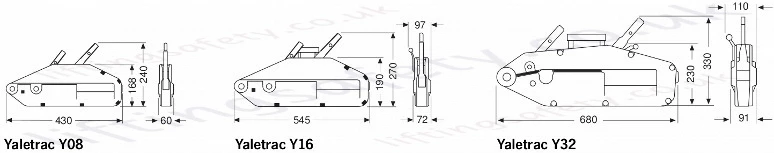

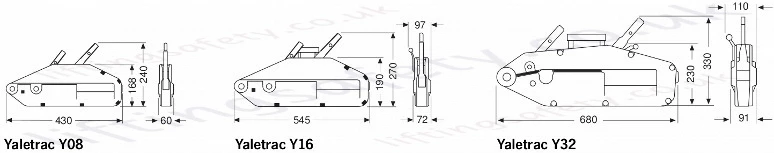

Dimensions

| Model | Capacity (WLL) | Wire Rope (diameter) mm | Rope advanced per double stroke (mm) | Lever pull at WLL daN | Lever length (mm) | Weight (without rope) kg | Rope Weight (kg/m) |

| Y08 | 800kg | 8.4 | 60 | 24 | 800 | 7.0 | 0.29 |

| Y16 | 1600kg | 11.5 | 60 | 30 | 790/1190 | 14.0 | 0.53 |

| Y32 | 3200kg | 16 | 40 | 50 | 790/1190 | 21.0 | 1.00 |

Optional Accessories:

- YaleTrac Storage Box

- Drum

- Standard Cable Reel

- For more information please phone our sales team on 01977 684600

Technical Specifications.

(approx. 0.1Mb)Yaletrac Operating Instructions

The operating instructions contain important information on how to handle the machine/hoist in a safe, correct and economic way. Acting in accordance with these instructions helps to avoid dangers, reduce repair costs and down time and to increase the reliability and lifetime of the achine/hoist. Anyone involved in doing any of the following work with the machine/hoist must read the operation instructions and act accordingly.

(approx. 1.3Mb)Pricing

0.8 tonne, 1.6 tonnes or 3.2 ton Lifting Capacity

All Rope are fused and tapered at one end. The other end is terminated with a Crosby eye hook in heart shaped thimble secured by a mechanical splice.

This product is an alternative to the Tirfor product which we also offer.

Yaletrac® cable pullers feature a lightweight, compact, high strength aluminium housing, smooth contour design with a large, flat bottom surface for increased stability in horizontal and vertical working positions.

Forward and reversing levers in tandem provide slim design and assure power transfer along the centre line.

Overload protection is by a shearing pin in the foward lever. Spare shear pins are conveniently located in the carrying handle or operating lever. A broken pin can be replaced without removing the load.

- A lever disengages the rope clamp system allowing easy, smooth installation of the wire rope.

- Yaletrac® uses a special flexible wire rope. It has six strands with a steel core.

- The rope is tapered at one end for easy threading and fitted with a safety hook on the other end.

- The parallel arrangement of the clamping system protects the wire rope by distributing the clamping forces evenly.

- A long rope advance per each lever stroke increases the working speed.

- The large opening in the top of the unit allows easy cleaning: simply flush the unit with water, apply motor oil for lubrication and the Yaletrac is again ready for use.

Dimensions

| Model | Capacity (WLL) | Wire Rope (diameter) mm | Rope advanced per double stroke (mm) | Lever pull at WLL daN | Lever length (mm) | Weight (without rope) kg | Rope Weight (kg/m) |

| Y08 | 800kg | 8.4 | 60 | 24 | 800 | 7.0 | 0.29 |

| Y16 | 1600kg | 11.5 | 60 | 30 | 790/1190 | 14.0 | 0.53 |

| Y32 | 3200kg | 16 | 40 | 50 | 790/1190 | 21.0 | 1.00 |

Optional Accessories:

- YaleTrac Storage Box

- Drum

- Standard Cable Reel

- For more information please phone our sales team on 01977 684600

Technical Specifications.

(approx. 0.1Mb)Yaletrac Operating Instructions

The operating instructions contain important information on how to handle the machine/hoist in a safe, correct and economic way. Acting in accordance with these instructions helps to avoid dangers, reduce repair costs and down time and to increase the reliability and lifetime of the achine/hoist. Anyone involved in doing any of the following work with the machine/hoist must read the operation instructions and act accordingly.

(approx. 1.3Mb)Products of Possible Interest

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.