Material Handling & Jacking Equipment

Manual handling equipment is designed to reduce the manual handling effort required and associated risk to the operator, to a minimum and you will find the range offered by LiftingSafety is vast. There are many subcategories of manual handling equipment available; they can be manually operated, electrically controlled, pneumatic (air-powered) or hydraulic-powered.

LiftingSafety offers a great range of lifting jacks as normally used to lift, lower and/or hold equipment, in numerous design styles to suit our customers jacking needs. Our jacks are manual or electrically operated and can be supplied with hydraulic or mechanical lifting.

If you have a manual handling issue and need a solution, we advise you to send an email to our technical team, who will do their best to offer the most appropriate solution.

Our staff are keen to offer the best solution rather than the most expensive options as we try our best to obtain new business and then to retain our customers. If you need any type of materials handling equipment we are here to assist – why not get in touch, and send us your enquiry today?

Load moving skates are mechanical handling equipment used to transport heavy machinery and other items in the work area. Machinery skates mainly use nylon, polyurethane or steel wheels / castors and work though are also less often fitted with roller tracks, like tank tracks (Economical and ideal for general workshop moving jobs, all types of machine tools, fabrication etc). Dependant on customer requirements we offer load moving systems with fixed and swivel castors or indeed a combination of both. Most of our materials skates are designed to be manually manoeuvred (push / Pull) though most can be assisted by a tug or fork truck. Materials load moving skates work best on a flat smooth surface free from dirt or other obstructions. All our load movers are individually load rated and / or rated as a set. Sets of machinery skates usually include one front steerable skate and a pair of fixed wheel rear trailing skates with a tie bar. We also sell many individual skates, roller pinch bars to manually raise a load and materials movers otherwise sometimes referred to as materials scoots (or scoots). We have tried to compile a range suitable for all professions and budgets, please contact our sales or technical staff if you need any assistance or a quotation.

LiftingSafety provides an extensive selection of high-pressure hydraulic lifting cylinders, rams, and hand pumps specifically designed for heavy-duty industrial applications. These single-action lifting cylinders typically utilize a remote hand pump, making them well-suited for confined spaces. The lifting cylinder is separate from the hand pump but connected via a hydraulic hose that can be extended as needed, allowing the operator to maintain a safe distance from the lift.

Our lifting cylinders operate at an impressive 700 Bar / 10,000 PSI. In our online catalogue, you’ll find hydraulic lifting systems capable of supporting up to 1000 tonnes across a variety of sizes and types. We offer flat or pad jacks, which are low in height, as well as standard and tall cylinders, including hollow center jacks. Many of our lifting cylinders feature locking nuts, providing a mechanical method to hold the load securely and prevent any unintended lowering.

Additionally, our single-stage rams come with a spring return, ensuring efficient operation. We also carry a robust selection of hydraulic hand pumps, both manual and electric, available with various reservoir capacities (amount of oil). Our pumps come in both single-stage and two-stage configurations; twin-stage pumps lift quickly at low pressure and automatically reduce the lifting speed as the oil pressure rises. Whether hand-operated or foot-operated, our hydraulic hand pumps are designed for reliability and performance.

LiftingSafety offer many types of lifting jack in our online catalogue in an attempt to offer a jacking / lifting equipment system to suit most jacking applications. All the jacks are manually operated with the lifting action being a mechanic ratchet jack or by a pressurized hydraulic system. Hydraulic lifting jacks have an integrated hand pump, mounted on to the jack body. Toe jacks are available in our online jacking catalogue with many different features including rotating body, optional toe heights and many choices for height of lift. Our Jack range is manufactured by quality / reputable lifting equipment manufacturers the likes of Yale, Tractel, Gunnebo and Pfaff (and more to be added shortly) at prices to suit most budgets. Lightweight aluminium jacks are available up to 100 tonne capacity with different stroke lengths. Some designed of toe jack allow the toe to be removed and with others the toe is a permanent part of the jack. Please be aware that most toe jacks have a reduced capacity when lifting off the toe; very few have 100% SWL when lifting off the toe. The purpose of the toe is to create a very low lifting point when a conventional jack is too tall to get under the load.

LiftingSafety provides in our online hand pallet truck catalogue probably the largest range of pallet trucks offered anywhere online. The overall range covers many pallet trucks from many leading lifting equipment and materials handling equipment manufacturers including, Yale, Little Mule, Tractel, Pfaff and many more to be added shortly. We sell pallet trucks from mainstream applications and hand pump trucks for specialised applications including the following: weighing trucks with scales, tilting pallet trucks, Atex pallet trucks, high lift pallet trucks, Corrosion resistant galvanized steel and stainless steel pump trucks. Amongst the features of our range is electric lift and powered travel hand pallet trucks and some with parking brakes fitted. Narrow, wide and long pallet trucks.... the list goes on. We have subdivided the range into pallet truck by user application then further sub-divided by manufacturer to assist our customers in navigating to the most appropriate product.

Stacker trucks are similar in design, operation and visually to hand pallet trucks, the key difference being the ability of a stacker truck to raise the load to a greater height. For user operation we offer pedestrian manoeuvred or with power travel and with materials lifting options as manual (no power) or battery lifting. There are many options in our online stacker catalogue offering height of lift and safe working load to meet with our customers’ requirements. Manual and electric stacker trucks can be supplied with forks or a load platform with the load lifted by a manual hydraulic hand pump or with a wire rope winch. Stacker trucks traditionally have forward facing stability legs which reduce the need for counter weight though we can also supply special bespoke manufactured counterbalanced stacker trucks. Forward facing stability legs also have the advance of making a stacker truck lighter and therefore easier to manually manoeuvre.

We are distributors for Genie Industries and leading suppliers Genie Material handling equipment including the Genie Load Lifter and Genie materials lifter for smaller applications and the Genie Superlift Advantage SLA, the Superlift Contractor SLC and the counterbalanced SLK for lifting applications up to 454kg SWL and a lifting height of up to 7.9 metre; all the Genie materials lifting equipment is suitable for indoor and outdoor use. The original Genie Hoist in was first introduced in 1966 and since then Genie Industries has been continually developing lifting equipment products for the work place. Genie makes top quality lightweight, cost effective material, totally portable with a massive variety of applications. It is the design, durability, quality and spare parts availability over many years that sets the Genie materials handling equipment apart from the copies that followed. They are possibly a little more costly to buy though it does work out cheaper over time in respect to lifetime savings. All Genie material handling equipment is quickly set-up ready to work and provides a one person set up & operation; in most cases they can be transported in many small light commercial vehicles.

The scissor lift table is a manual handing aid and are offered online presented in two categories; as mobile scissor lift tables and static scissor lift tables (no moving / fixed). Castors are fitted to tables that need to be moved between jobs or used to move the load while loaded. Static scissor lifting tables are permanently left in place; they can be countersunk into the floor so that when retracted the table top is flush to the floor surface or free standing / bolted to a floor. Fixed scissor lift tables are much more stable and therefore better suited to greater height of lift and capacities. Fixed scissor lift tables are often used in production processes of as loading platforms. The key features of a scissor lift table are as follows; Capacity (The maximum weight that the table can safety lift). The table top dimensions (the size of the table needed to support the load / carry out the task). The height of lift needed (this refers to the maximum height as well as the minimum lowered height). Working environment is a consideration that should not be overlooked. (We can make lifting tables for outdoor use with corrosion protection such as galvanized or stainless steel construction as also used in the food manufacturing industries.)

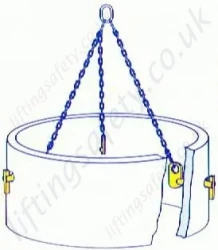

LiftingSafety offer online a massive online Drum Handling Equipment category with all types of devices to assist or remove the manual handing effort required when lifting, pulling, turning (rotating right, left, front and back) or dispensing from a steel or plastic drum. To make navigation as simple as possible we have divided all the products in this category by user application, these domains are Fork lift truck mounted drum handling equipment, Hoist hook suspended drum handling equipment and manually manoeuvred drum handling equipment (pedestrian drum handling equipment) we have then slit the products onto attachments suitable for particular drum types; steel drums, “L” Ring Drums, 110 litre Fibre drums and Egg Shaped Plastic Drums. We offer drum attachments that grip around the circumference, that strap around the drum, hydraulic operated grabs, rim grip attachments or top ring connecting. All our drum handling equipment is good quality and mostly made here in the UK.

Crane Forks

Crane forks are a hook suspended piece of lifting equipment used to lift pallets of equipment in areas of the work place that a fork lift truck cannot reach. Standard Crane lifting forks are available in many different capacities up to 5 tonne SWL. Special bespoke manufactured crane forks can be made to suit our customers’ requirements both in physical dimensions and capacity. There are two main types of crane fork, manual balance and automatic balance crane forks. The manual balance versions need the operator to adjust the hoist hook position on the forks to ensure the load is picked up correctly, and not dangerously tipping forward with the risk that the load could be accidently dropped. Auto balance / self balancing crane forks require no manual intervention to level the load though do have required a minimum of 20% of the maximum SWL to work correctly, for example 1 tonne crane forks must be loaded with a minimum of 200kg. Crane forks are equipped with adjustable tines, height adjustable and an automatic balancing system. Crane forks with automatic balancing* tend to point their tines upward when being transported. This prevents the load from unintentionally slipping off the tines.

Industrial load cells (also commonly referred to as a load indicator or crane weigher) are a safety product used by all industries to show the weight that the weight of the equipment suspended underneath it, they incorporate a strain gauge to measure the force needed to cause mechanical deformation of the load pin.

Load cells are most commonly attached to a lifting equipment hoist to ensure that the crane is not overloaded. When a crane weigher/load cell is used attached to a hook the operator can clearly see as the load is being applied to the hoist; as the operator begins to lift the weight being taken by the load cell increases until the load is fully suspended. At any point as the load increases, the operator observes an overload they can reverse the lift.

LiftingSafety offer online three main categories; Crane Weighers to a maximum capacity of 35 tonnes which have a master ring and a swivel hook built into the body of the cell, the master ring connects to the hoisting hook and the swivel hook to the load. The Crane weigher permanently displays the load in a large LED or LCD onboard display. These are normally left semi-permanently on the crane hook rather than used as / when needed.

The next category is the eye and eye type digital load cells which can be supplied to 300 tonnes with IP protection to IP66 and are suitable for heavy industrial and offshore use with display options, onboard display, cable with handset and radio remote control.

Finally, we offer special application load cells for example load shackles, load pins, compressive load cells and mechanical load clocks. Technically a load cell is a transducer used to convert a force to an electrical signal by the force deforming a strain gauge which measures the deformation electrically.

A tool spring balancer are a type of positioning equipment that will take the weight (neutralise the weight) of a tool or equipment which is attached to it and this is achieved by applying the correct tensioning a spring of the tool balancer. Because the tool spring balancer now takes the load effectively the item is now nearly weightless. If slightly more tension is applied the return spring of the tool balancer than the self weight of the tool the tool being balanced then the tool will retract slowly; the more tension that is applied to the spring the harder it will be for the operator to pull down the tool. For example, if the if the tool self weight is 50kg and 51kg of load tension is applied to the balancer spring then it will take 1kg of user effort to pull back the tool. This means a tool or piece of equipment can be positioned where ever it is required, and moved with the minimum of effort from the user. The spring balancer can be set so that the tool or equipment will not move until the user repositions it manually.

LiftingSafety offers online a huge range of platform trucks and trolleys / material handling solutions such as; Box Trucks with mesh lifting and hinge sided trucks; plastic box trucks. Platform Trucks that have options single sided; double sided; three or four sided; mesh sided; rod sided; or plywood sided platform trucks. We offer stair climbers and a great range of trolleys: Baggage trolleys; balance trolleys; folding trucks; high load trucks; high shelf; tyre trolleys; and order picking trolleys.. our range of sack Trucks with options as Light duty; medium duty; heavy duty; 3 way sack trucks and chair carrying trucks with compact; plate shoe; and star wheel sack trucks. Let us know if you cannot find the product you need and we will offer a suitable product or offer to manufacture a special bespoke truck or trolley.

Material handling equipment within lifting safety contains handling products for various material types. Products such as scissor lifts, pallet trucks and stacker truck are available within this category and are available as quality or economy units. Quality trucks tend to be a little more expensive than the low cost economy units, however quality means the unit will have a longer life cycle and if/when your material handling unit needs a repair the spare parts will be alot more readily available.

Genie lifts and various attachments are also online within this listing which are handling equipment to the highest quality.

Box trucks, platform trucks/trolleys and sack trucks are also listed along with stair climbers and trolleys which contains items such as baggage handling, cages for produce, order picking trolleys. etc.

Jacks are an essential piece of lifting equipment used by most industries. At SELS we offer jacks for most application and to suit most budgets. There are three main types of jacks; Hydraulic jacks that either have a self contained hydraulic pump (built-in) or a remote / separate hand pump. There are also mechanical / ratchet jacks and screw jacks. We offer a choice with many different capacities, heights of lift (stroke) and many with the ability to lift of the head or toe; otherwise known as toe jacks. Most have a reduced capacity when lifting from the toe though some can achieve 100% SWL on head and toe.