Lifting Clamps (Lifting & Pulling Applications)

LiftingSafety provides an extensive range of lifting clamps available online, catering to all user needs. We stock only top-quality clamps from esteemed manufacturers such as Camlok, Yale, Tractel, Riley Superclamp, Crosby, and IP Clamps, suitable for handling various materials including steel, concrete, plasterboard, glass, and other delicate items.

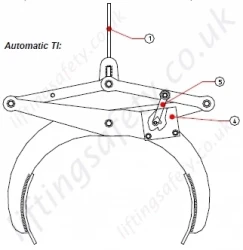

Our clamps are expertly designed for lifting applications, pulling equipment, tensioning loads, and securing items in position. You'll find a variety of design styles, including cam locking, screw-lock, scissor action lifting, and suspension clamps. The primary purpose of clamps from LiftingSafety is to manage steel plates and various steel profiles, with our main categories comprising vertical and horizontal plate clamps, as well as beam clamps for lifting and suspension.

In addition, our online catalogue features numerous other categories, such as pulling clamps, non-marking clamps, drum handling clamps, groundwork and construction clamps, coil handling clamps, rail clamps, and drop test clamps. We’ve organized our selection by the user application, further subdivided by the manufacturer to ensure you can easily find the ideal clamp for your needs.

LiftingSafety also offers maintenance and repair services for clamps, alongside user training to ensure safe and competent operation. Each clamp we list is manufactured to high standards and has the necessary certification and technical support. For any assistance, feel free to reach out to our sales or technical team.

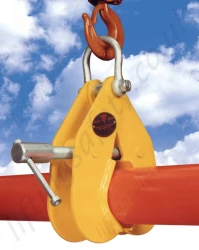

A range of clamps that are designed to lift RSJ/I-beams (I / H profile) or that is to suspend from a beam. The operation and user manual must be understood and followed correctly to ensure that a clamp for suspending from a beam is not used to lift a beam. LiftingSafety only offers top-quality beam clamps from reputable manufacturers. Many of these products are very similar with small feature differences which make them more suitable to particular operations. Offering a wide selection ensures our customers have a good choice in design, quality, price and stock availability.

Vertical plate clamps grip to the steel plate by the teeth biting into the surface of the plate, otherwise referred to as defamation. We offer from manufactured like Yale, Pfaff, Camlok, Tractel, Crosby and Riley who are all quality lifting equipment manufacturers. There are a variety of options available such as automatic locking and various plate thicknesses for the same range of clamps. We offer vertical plate lifting clamps specifically designed for special application for example clamping to very hard materials, very thin materials, small profile clamps etc...Non-marking clamps are a very popular item at they cause no damage to the item they are gripping to! Vertical plate clamps pick and carry steel plates in the vertical plain though options with articulating (swivel) lifting eyes are also available that can connect to a horizontal plate then lift & turn to the vertical position.

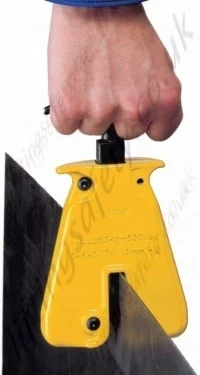

Horizontal plate lifting clamps are designed to firmly grip steel plates, either by their teeth biting into the surface—also known as defamation—or by utilizing multiple clamps to support and lift the load. Sometimes referred to as plate lifting hooks, we provide these clamps in various styles, including options with teeth, roller toes, smooth toes, and non-marking lined faces.

Our range includes horizontal plate clamps ideal for transferring, tilting, and stacking steel plates laid out horizontally. We source our products from reputable manufacturers such as Camlok, Tractel, Crosby, and Riley, ensuring top-quality lifting equipment.

We pride ourselves on offering a wide selection of clamps, aiming to provide our customers with plenty of choices at competitive prices. The clamps available online cater to various plate widths, with some featuring adjustable settings. We can supply horizontal clamps in capacities suitable for most lifting applications. Note that some clamps are rated individually while others are rated in sets. Please refer to the operation and user manual to ensure safe and proper use.

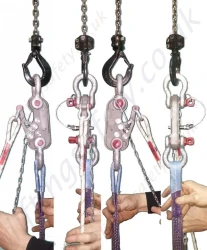

LiftingSafety offer pulling clamps in the section of our on-line catalogue; meant for pulling or tensioning the load and not for lifting equipment applications. Pulling clamps tend to be a screw lock design, the tighter the user tightens the screw thread the more grip is applied. Pulling Clamps are mostly used as anchor points, from this a piece of lifting equipment will be attached to allow two surfaced to be pulled together for example a fabrications to be pulled together and positioned so that they can be welded. Pulling clamps offered her are made by Camlok, Yale and Crosby (IP Clamps) and they usually have a cam pad that when a load is applied to the clamp the circular toothed pad pivots in a cam action, gripping the load, the harder the pull the greater the friction grip by the clamp. To avoid accidents please always follow the manufacturer’s operation user guide as the are limitation with surfaces and application on pulling and tensioning clamps

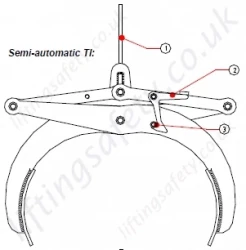

Scissor grip lifting claps are used for gripping and lifting all types of equipment, steel, concrete, plasterboard, plastic, glass and many more. On all the scissor grip lamps the gripping force is generated by the scissor action, some of these clamps bit into and before the lifting surface, others are none marking pads or a lip under the load being lifted. All our scissor lifting clamps are adjustable - they have an adjustable range that they can be used within. We supply clamps made by Tractel and Camlok and the clamps can be used to lift square and round material. Please contact our sales or technical team if you can’t find the clamp that best suits your application as we can make specials to our customers specification.

LiftingSafety offer a good range on non-marking clamps from Tractel, Camlok and from Crosby IP Clamps. In different industries they are also referred to as non maring, none marking clamps, board clamp, glass clamp, panel clapms etc..... These hook suspended clamps are used where no deformation of the item lifted is allowed. The clamps will grip and lift the load wile causing no damage to the load. The other advantage of the non marking range of clamps is that there is no minimum SWL, with other types of lifting clamp the design dictates that 10% or in some cases 20% of the maximum SWL must be applied to the clamp for the gripping action to work, this is not the case with this range of lifting clamps though the user must always refer to the operation and user manual prior to use. All the clamps have jaws that adjust to accommodate different thicknesses of material, having a wide range mans there may be a standard product to suit most lifting applications; if this is not the case we can manufacture and supply special bespoke non marking clamps to suit the end users specification.

Steel section lifting clamps are offered in our lifting claps catalogue as manufactured by quality lifting equipment manufacturers like Tractel, Camlok, Crosby IP Clamps, Riley and Yale with more to be added in the near future. We offer value through choice. Greater choice means that there is a better chance we will have a clamp with the special key features that you are looking for! This category is populated with clamps to lift steel profiles, raw materials in different sizes and shapes as you would expect to see at a steel stockholder; materials such as I Beams (RSJ) rolled steel joists or Universal beam, bulb bars, angle iron, round shaped steel sections and square section (hollow section). We offer clamps lift most steel profiles though please contact our sales team if you do not see the lifting clam that you are looking for.

Drum lifting clams are hook suspended and commonly used on an overhead crane or fork truck attachment to lift, manoeuvre, turn and dispense steel and plastic drums. We offer options to clamp onto the drum and others to grip around the circumference of the drum, usually using a scissor action; some carry the drum vertically and others lift the drum horizontally. Some of the other drum lifting clamps that we sell are used to lift, rotate then pour out the contents in a controlled way. Presently we sell drum clamps made by Camlok, Crosby IP and Tractel though are to list new products from different manufacturers online in the near future. In this category we also offer gas cylinder lifting clamps for lifting welding bottles, oxygen, propane and acetylene.

Groundwork and construction clamps are one of our most active clam sections / categories in our lifting clams catalogue and are manufactured by Camlok, Tractel, Crosby IP Clamps and Riley Superclamps – all top quality manufacturers. Amongst the items sold online are pile clamps, pipe hooks, coil lifting clamps, block grabs and brick grabs. Weather our customers need a clamp to lift a kerb stone or a concrete manhole section we have a clam to lift it. Thank you for taking a look at our construction industry clamps, we look forward to receiving your enquiry.

We offer steel coil lifting and handling clamps as manufactured by Camlok and Tractel that are designed for lifting and handling pipe sections, coils, rolls and rings etc. in the horizontal position. With some coil clamps that lift by a cantilever action if collared pipes are to be lifted adjust the balance accordingly. Other coil clamps use a twin arm C hook method designed to lift loads in the horizontal position and are ideal for narrow aisle handling applications. Coil Turning Hook is a universal C hook, incorporating a tipping feature which allows the coil to be lifted or lowered, whether the coil is flat or upright. The tipping device also serves the purpose of preventing accidental slipping of the load during transport. Tractel TOPAL CR are designed for the lifting of coils and/or turning over from the horizontal to the vertical position and vice versa.

Locomotive rail lifting clamps offered in our clamp lifting catalogue are made by Tractel, Camlok, Riley and Yale and are designed for lifting and handling a single rail at a time or for many loco rails at the same time as a multi rail lifting clamps. We offer many different ways to lift and pull rail sections for example; rail pulling clamps have been designed for use when positioning rail sections, Multi Rail Clamps are used for the fast bulk handling of a specific rail section though we also offer versions designed for the quick and simple bulk handling of ALL rail sections. screw lock type rail clamp is designed to be attached to the rail head via a screw thread operated mechanism. Some rail clamps are designed to be used in pairs with a lifting beam and to suit a specific rail profile and others are adjustable to cover many rail sections. Please contact our sales or engineering staff for assistance.

This Drop Test clamp is a unique product to LiftingSafety, having developed many years ago for dropping concrete sea defence weights into the sea the drop test clamp is making its revival. We decided to optimize the dropping clamp and have taken orders from all industry sectors for applications that would never have been considered at the time it was envisaged. This drop test clamp otherwise often referred to as a dropping clamp can be used to remotely release load weighing up to 25 tonnes or even greater capacities on request. The load is attached to the clamp by a master link. The clamp has an interlock system that will prevent accidental release of the load if one of the release rope is pulled during the lifting phase of the operation The dropping of any load is a dangerous activity and therefore we emphasise that the operation and user manual must be adhered to in along with the user risk assessment and method statement.

We offer two optional design totally unique top mounted beam clamp for lifting equipment installation that are light weight construction can be fitted quickly. The clamp is fitted to the top beam flanges and was designed assist help when positioning heavy load bearing lifting equipment to the lower flange and reduce the risk of accidents. The two options have 1 or 2 lifting / suspension points that cantilever to the side of the runway beam. Temporary lifting gear is attached to this suspension then used to raise the main lifting equipment to allow installation to the underside of the runway beam.

Unsure of the best clamp for your application?

Get in touch - Drop us an email or give us a call. We are happy to help and will do our best to assist you in finding the perfect clamp for your application.