General Industrial Lifting Equipment

Probably one of the largest online ranges of general and specialist lifting equipment including; beam trolleys, all types of hoists, rigging equipment, beam/plate clamps, lifting magnets, pulley sheaves and lifting equipment identification tags/systems etc., from a vast array of suppliers and manufacturers across the world.

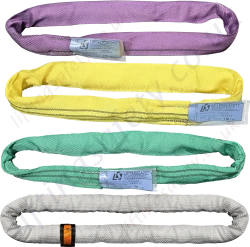

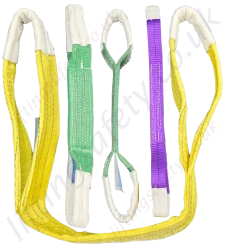

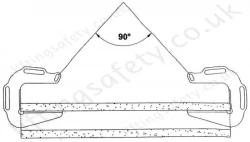

LiftingSafety offers a range of synthetic (man-made fibre) lifting slings designed to be lightweight and help prevent or minimise damage to the items being lifted. A synthetic webbing sling is also often referred to by a variety of different names, such as lifting strap/strop, belt sling, polyester lifting sling, flat web lifting sling, belt webbing, woven sling, simplex or duplex sling, round sling or endless slings.

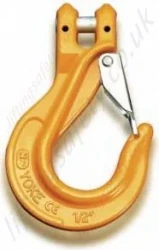

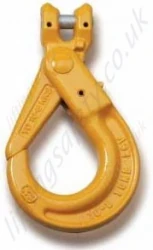

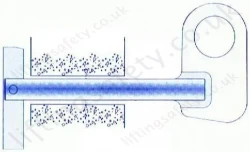

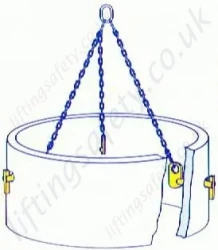

Wire rope slings from LiftingSafety are made to our customer’s specifications with an online choice of terminations and end fittings that include soft eyes, thimble eyes or with a big choice of hooks. As with our chain slings the wire rope slings offered online can be supplied as one, two, three or four leg design and can be made from galvanised steel wire rope or stainless steel wire rope and in any length and safe working load. All of our wire rope slings are made to order, bespoke products so if you cannot configure the exact product specification needed then please contact our sales team who will be happy to email you a competitive quote. End fittings/terminations offered online are; fused and tapered, ferrule secured thimble hard eye, ferrule secured soft eye, flemish eye according to Din 13414-1, captivated shackle (permanent), master ring, sling hooks (traditional safety latch/catch type), self-locking safety hooks, foundry hook, swivel sling hook and swivel self-locking hook.

Lifting capacity options (WLL - Working Load Limit) are available online from 95kg all the way up to 125 tonnes on a single M150 bolt, or 250 tonnes on twelve M48 bolts, all as standard products, but greater capacities can also be special/bespoke manufactured.

This category is populated with beam trolleys, these are load suspension trolleys designed to have a load or lifting equipment suspended underneath then traverse along a runway lifting beam (otherwise known as a monorail lifting beam made from a rolled steel joist (RSJ) or universal beam (UB) or Universal Column (UC). We offer in our online catalogue shop four sections, different types of Monorail runway trolley. Beam trolleys are a mobile anchorage point that can be fitted onto a lifting beam to suspend lifting equipment beneath, such as a chain hoist. This allows the load to travel along the direction of the lifting beam. A Beam trolley can also be referred to as a load trolleys, a beam runner, 'I' beam crane trolleys, a beam flange roller or girder monkeys. This section is for manual push travel beam trolleys and geared travel runway beam trolleys (Chain drive). Gear travel units are moved along the beam by operating a hand chain and give a greater level of control especially on larger capacities. Most trolleys are adjustable and some are quick release. We offer heavy-duty and low-head room trolleys, also swivel truck trolleys to negotiate tight radius bends on runway tracks where required.

Lifting equipment and height safety gear in the UK and around the world must undergo regular thorough examinations to ensure they remain safe for use. The inspection timeline for lifting gear varies based on the type of equipment, typically occurring every six (6) or twelve (12) months. Accessories for lifting equipment require inspections twice a year, while lifting machines are assessed annually.

To help users easily identify whether the equipment is still within its acceptable service period, we provide colour-coded tags. These serve as a visual cue that the equipment is generally safe to use, though it’s essential to conduct user inspections both before and after operation. Additionally, our lifting equipment identification tags are perfect for confirming that height safety and fall arrest gear are still compliant with inspection requirements.