Rigging Gear; Riggers Lifting Equipment

LiftingSafety offers online in this category general lifting tackle used under the hook commonly referred to as "rigging and slinging equipment", used by the rigger to make the lifting process safe. Many users refer to the items contained within this category as lifting accessories or loose lifting gear.

Many of the items are also listed in other relevant categories within our online store, advertised here are Lifting Eye Bolts and Lifting Slings, Chain Fittings, Bow shackles and D-shackles and Crane Blocks. We sell quality rigging accessories from reputable manufacturers like Crosby, Hackett’s, McKissick etc.

Our staff have excellent product and technical knowledge so please feel free to contact our team at any time if you need any assistance.

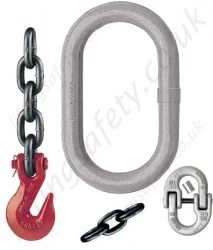

Master rings and load suspension eyes are connectors used between the lifting hook and the load to be lifted. Master rings are most commonly used on lifting chain assemblies as the upper link though there are many other industrial applications which they could be used for. All the connectors in this category are certified for lifting applications. There are round rings , oval lifting rings and par shaped links in different sizes and capacities form quality lifting equipment manufacturers such as Hackett's and Crosby. Contact our team for a competitive quotation.

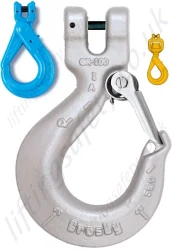

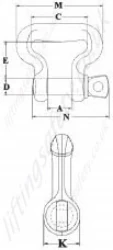

In this section of our online catalogue we cave collated all the lifting and pulling hooks into one place to make it easy for our customers to browse for a suitable hook to suit their specific application. Amongst the products offered are automatic lifting hooks, swivel and eye hooks, clevis, shank and chain hooks. We have brought hooks together from all other categories including products that incorporate a hook such as a rigging screw turn buckle and load swivels with hooks. We look forward to receiving your enquiry.

We offer rigging screws and turnbuckles in a great range of sizes (Dimensions) and capacities with a choice of end fittings; they are designed to tension and hold in place a wire line, (wire rope) or other piece of equipment. Rigging screws / turnbuckles are also used for lifting applications though before using to lift with please check with the operation and used manual to ensure that they are certified for lifting; the reason being that many manufacturers only certify for pulling applications. We offer closed body and open body versions. A turnbuckle can be adjusted when under load to pull two items together or to tension / loosen. They can also be used to take slack out a system if there is any movement or stretch over time. The lock nuts will hold maintain the bearing to bearing when in use that can otherwise creep / slacken due to vibration and other reasons. Standard turnbuckles go up to 34 tonne though specials are available to meet our customers’ requirements. Each range come is different lengths so that dependant on the safe working load that you need and so there should always be an option with the correct amount of adjustment. (Often referred to a take-up) to suit our customers' needs. Option end terminations are: hook & hook, hook & eye, eye & eye, Jaw & eye and Jaw and jaw. We make specials from stainless steel and have many more products due to be listed online in the near future. Thank you for looking.

LiftingSafety offer fittings, products and accessories to be used with steel wire rope and to manufacture wire rope lifting assemblies. This includes rigging equipment for connecting wire ropes, items like wire rope grips Bulldog clips fast grip double bolt clips made from galvanised steel and stainless steel. We also offer a category with end terminations for steel wire rope including thimble eyes, spelter sockets, wedge sockets and swage fittings including a range of hooks. We also sell wire rope sleeves and swaging machines for pressing the sleeves to make up wire rope assemblies.

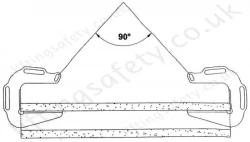

In this category we offer mainly snatch block and crane blocks which are both sheave blocks. Snatch blocks used to deflect a wire rope and can be supplied as Tail Board, with top hook suspension or as shackle suspended. They are often used suspended from a hook for lifting equipment application s though just as often used for pulling applications. A number of snatch blocks can be rigged multi reeved to increase the capacity (SWL). The more times the wire line is reeved through a snatch block / crane block the greater the safe lifting capacity of the hoist or winch that is pulling the wire rope. This is why crane blocks are reeved many times, to increase the capacity. On the negative side every time the wire line is reeved the lifting speed is reduced by 50%. We offer quality lifting equipment as made by Crosby, McKissick, Western, Tractel, Yale and Lebus with more manufacturers to be added to the catalogue in the near future.

Pulley sheaves otherwise known as pulley wheels are used for deflecting the direction of a steel wire rope or a synthetic rope; to change the direction that the rope travels usually between the hoist and the hook meaning that the wire rope path can be located in a safe area. Sheaves are also used with steel wire ropes reeved back and forth to increase the capacity or safe working load of the lifting equipment. Sheaves are available to suit all wire line sizes and can be supplied with many bearing types, either both a plain bore (no bearing) or with centre bronze bush bearing or needle roller bearings. Other options include common bore pulley sheaves, tapered bearing type pulleys, and many options of sheave that are integrated into housing. Sheaved supplied mounted in to a housing are often known as lead blocks and can be bolted to the anchorage surface, welded or fixed by a shackle. Some lead blocks can swivel and other rotate to the direction of the load. We offer sheaves from top level reputable manufacturers including McKissick, Crosby, Pfaff, and Western with options for fast speed operation by a powered hoist or winch (electric chain hoist / pneumatic pulling winch) or slow line speed as would be the case with a hand operated hoist or hand winch. LiftingSafety also manufacture special sheaves to our customers' requirements so please contact us with your enquiry.

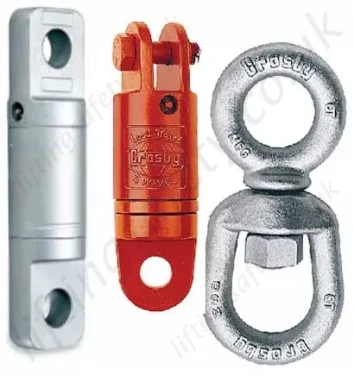

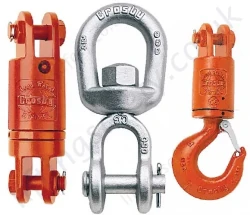

Load Swivels are a piece of lifting equipment that adjusts to the movement of the load to avoid putting stress on either the lifting equipment or on the support structure. Swivels come as standard with options end fittings including hooks, jaws, eyes or shackles dependant on our customers application. We offer many different types of swivel as standard though the majority are made by Crosby, a top quality manufacturer; they include contact angular swivels, tapered bearing swivels and chain swivels. We can also supply specials, bespoke swivels to our customer’s specification, size and safe working load up to 1000 tonne capacity, including swivels made from stainless steel. Please feel free to contact our sales team who will assist with any enquiries and quote accordingly.

Load restraint equipment us used to tie down equipment stopping it from moving. Load restraint and cargo restraint products are not lifting equipment and cannot be used for lifting application under any circumstances. Items need restraining from movement when being transported between locations for example road and rail freight. If the cargo is not restrained it could easily cause an accident falling from the vehicle or train. The products fall into two categories, cargo restraint ratchet straps and load binders, both are available in different sizes , capacities and lengths to suit our customers applications. Ratchet straps have a steel ratchet handle with a polyester webbing sling. Single part ratchet straps have the long webbing sling fitted permanently to the ratchet. 2 part ratchet straps have a separate web sling with end fittings. The web sling can be supplied with different end fittings dependant on our customer's applications, usually hook or eye or buckle (many types). We also supply cam buckle restraint straps, lorry straps, one way straps and stainless steel cargo restraint latchet straps. Load binders are to achieve exactly the same function as ratchet straps.

They are totally made from steel using a chain sling with grab hook as opposed to a webbing sling. There are differing styles available, ratchet load binders and lever action load binders. these are used in applications where items with shape edge's or abrasive surfaced need to be restrained; surfaces that would damage or cut a polyester sling ratchet load binder and can be supplied in different configurations with a hook or eye termination or with a permanently fitted restraint chain fitted.

Most items of lifting equipment in our catalogue have many optional products from other lifting equipment manufacturers and therefore fill a category dedicated to that range of products. Here we have items that are unique to our web site where no competitive items exist. As other products arrive online items will move from this category into their own dedicated list of product.

In this category we offer the complete Crosby Group Catalogue of lifting and rigging equipment and accessories. The Crosby Group was a goal to develop into a single source for lifting and rigging accessories targeted lifting industry and material handling industry with the highest levels of quality control, We at Lifting Safety are the route to market with probable the most comprehensive and easily navigated Crosby catalogue seen anywhere on the web across the globe. Through a creative program of product development and the Crosby group has grown into what we considered the standard that all other manufacturers’ strive to achieve. When buying Crosby, you’re buying more than simply a product, you're buying uncompromised Quality. Crosby’s competitors' products cannot be substituted in place of Crosby products just because they "look" alike. Crosby Group Lifting equipment products are manufactured with the highest design factors in the industry. Crosby group rigging products are better able to withstand abusive field conditions because of the improved impact and fatigue features designed into every item.