Runway Beam Monorail Crane Trolleys, Push, Geared & Electric

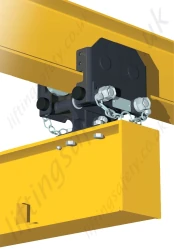

This category is populated with beam trolleys, these are load suspension trolleys designed to have a load or lifting equipment suspended underneath then traverse along a runway lifting beam (otherwise known as a monorail lifting beam made from a rolled steel joist (RSJ) or universal beam (UB) or Universal Column (UC). We offer in our online catalogue shop four sections, different types of Monorail runway trolley. Beam trolleys are a mobile anchorage point that can be fitted onto a lifting beam to suspend lifting equipment beneath, such as a chain hoist. This allows the load to travel along the direction of the lifting beam. A Beam trolley can also be referred to as a load trolleys, a beam runner, 'I' beam crane trolleys, a beam flange roller or girder monkeys. This section is for manual push travel beam trolleys and geared travel runway beam trolleys (Chain drive). Gear travel units are moved along the beam by operating a hand chain and give a greater level of control especially on larger capacities. Most trolleys are adjustable and some are quick release. We offer heavy-duty and low-head room trolleys, also swivel truck trolleys to negotiate tight radius bends on runway tracks where required.

Electric Travel Beam Trolleys provide the same basic function as a manual trolley except has electric powered travel along the beam controlled by pendant control or other.

- Our range of electric travel trolleys are adjustable to suit different beam sizes and have different power supply options for example: 1Ph (110v or 240v - single phase) and 3Ph (400v or 415v - 3 phase), also single speed, dual speed and variable speed travel units are available.

- An Electric trolley eliminates manual handling issues and can be used in environments that are unsuitable for manual operation, e.g. when used high up, out of reach, above deep water or chemicals.

- The Kito MR2 & Yale VTE are our most popular unit though we can also supply from many other manufacturers such as Morris, Verlinde, Pfaff etc...

Articulating crane trolleys are designed to be used in pairs to install a mobile crane bridge between two parallel RSJ's in the roof space. Thus creating a simple, low cost push/pull (manual) or electric overhead crane system.

- The crane trolley will articulate (twist) to prevent them crabbing; this is when the trolley castors bite into the 'downshop' parallel beams.

- Please contact our technical staff with your desired SWL/WLL (capacity), beam sizes and crane cross travel span, we will then help you specify the overhead crane trolleys that best suits your application.

Beam trolleys are a mobile anchorage point that can be fitted onto a lifting beam to suspend lifting equipment beneath, such as a chain hoist. This allows the load to travel along the direction of the lifting beam.

- A Beam trolley can also be referred to as a load trolleys, a beam runner, 'I' beam crane trolleys, a beam flange roller or girder monkeys.

- This section is for manual push travel trolleys and geared travel runway beam trolleys. Gear travel units are moved along the beam by operating a hand chain.

- Most trolleys are adjustable and some are quick release. We offer heavy-duty and low-head room trolleys, also swivel truck trolleys to negotiate tight radius bends on runway tracks where required.

- Please contact us if you require a unit which is not listed on this page.