-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Lifting Slings and Components

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Runway Beam Monorail Crane Trolleys, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms and Jib Cranes

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

- Man-riding Hoists & Rescue Winches

-

Fall Arrest & Man-riding Systems

- Fall Arrest Davit Arms & Posts for Working at Height

- Sala Advanced Davit Arm Systems and Components

- Xtirpa Confined Space Davit Arm Systems and Components

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding & Rescue Tripods & Quadpods

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

- Home/

- Lifting Equipment/

- Rigging Gear; Riggers Lifting Equipment/

- Crosby Lifting Equipment & Rigging Catalogue/

- Crosby Rigging Accessories/

- Crosby Lifting Eyes/

- Crosby 'S264' Pad Eyes, WLL Range from 295kg to 3265kg

Crosby 'S264' Pad Eyes, WLL Range from 295kg to 3265kg

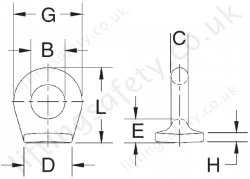

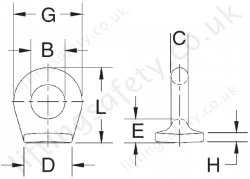

Crosby weld on pad eyes / lifting eyes.

Crosby S-264 / CPE-2432

The Crosby S264 weld on eye bolt is probably one of the most popular Crosby pieces of rigging equipment that we offer and commonly used on farm machinery, trucks, steel hulled marine vessels and many other types of material handling equipment.Please make a reference to the American Welding Society specifications for the proper welding procedures.

- Forged Steel — Quenched and Tempered.

- Forged from 1035 Carbon Steel.

- Excellent welding qualities.

- Widely used on farm machinery, trucks, steel hulled marine vessels and material handling equipment.

- Reference American Welding Society specifications for proper welding procedures

Pad Eye Strengths

Crosby Pad Eyes are lifting eye bolts for welding on to a suitable support structure to create a certified lifting point, they are designed to be attached to any structure, equipment, vehicles or machinery in which there is a need or desire for an eye, without the drilling and/or threading required for an threaded shank eyebolt. The normal method of attachment for pad eyes is by welding. Since Crosby cannot control the method of attachment (i.e. weld quality and size), a Working Load Limit is not provided for pad eyes. An approximate strength level for the eye of the pad eyes is:

Note: These capacities are only approximations and should not be taken as a guaranteed Working Load Limit.)

Metric Dimensions & Specifications

| Size No.* | S-264 Stock No. | Weight Per 100 (kg) | Dimensions (mm) | ||||||

| B | C | D | E | G | H | L | |||

| * 0 | 1090722 | 1.27 | 6.35 | 4.85 | 16.0 | 7.85 | 16.0 | 2.30 | 19.1 |

| * 1 | 1090740 | 2.95 | 9.65 | 6.35 | 22.4 | 10.4 | 22.4 | 3.30 | 26.2 |

| * 1.5 | 1090768 | 4.72 | 16.0 | 6.35 | 25.4 | 11.2 | 28.7 | 4.05 | 33.3 |

| 2 | 1090786 | 9.57 | 19.1 | 9.65 | 26.9 | 12.7 | 38.1 | 4.85 | 41.4 |

| 4 | 1090802 | 23.7 | 25.4 | 14.2 | 36.6 | 19.8 | 54.0 | 5.60 | 59.5 |

| 5 | 1090820 | 37.4 | 31.8 | 17.5 | 44.5 | 20.6 | 67.0 | 6.35 | 70.0 |

The Crosby S264 weld on eye bolt is probably one of the most popular Crosby pieces of rigging equipment that we offer and commonly used on farm machinery, trucks, steel hulled marine vessels and many other types of material handling equipment.Please make a reference to the American Welding Society specifications for the proper welding procedures.

- Forged Steel — Quenched and Tempered.

- Forged from 1035 Carbon Steel.

- Excellent welding qualities.

- Widely used on farm machinery, trucks, steel hulled marine vessels and material handling equipment.

- Reference American Welding Society specifications for proper welding procedures

Pad Eye Strengths

Crosby Pad Eyes are lifting eye bolts for welding on to a suitable support structure to create a certified lifting point, they are designed to be attached to any structure, equipment, vehicles or machinery in which there is a need or desire for an eye, without the drilling and/or threading required for an threaded shank eyebolt. The normal method of attachment for pad eyes is by welding. Since Crosby cannot control the method of attachment (i.e. weld quality and size), a Working Load Limit is not provided for pad eyes. An approximate strength level for the eye of the pad eyes is:

Note: These capacities are only approximations and should not be taken as a guaranteed Working Load Limit.)

Metric Dimensions & Specifications

| Size No.* | S-264 Stock No. | Weight Per 100 (kg) | Dimensions (mm) | ||||||

| B | C | D | E | G | H | L | |||

| * 0 | 1090722 | 1.27 | 6.35 | 4.85 | 16.0 | 7.85 | 16.0 | 2.30 | 19.1 |

| * 1 | 1090740 | 2.95 | 9.65 | 6.35 | 22.4 | 10.4 | 22.4 | 3.30 | 26.2 |

| * 1.5 | 1090768 | 4.72 | 16.0 | 6.35 | 25.4 | 11.2 | 28.7 | 4.05 | 33.3 |

| 2 | 1090786 | 9.57 | 19.1 | 9.65 | 26.9 | 12.7 | 38.1 | 4.85 | 41.4 |

| 4 | 1090802 | 23.7 | 25.4 | 14.2 | 36.6 | 19.8 | 54.0 | 5.60 | 59.5 |

| 5 | 1090820 | 37.4 | 31.8 | 17.5 | 44.5 | 20.6 | 67.0 | 6.35 | 70.0 |

Products of Possible Interest

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.