-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Fibre Lifting Slings

- Chain Slings & Components

- Lifting and Lashing Chain

- Wire Rope Slings & Assemblies

- Shackles

- Eye Bolts and Eye Nuts

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Runway Beam Monorail Crane Trolleys, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms and Jib Cranes

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

- Man-riding Hoists & Rescue Winches

-

Fall Arrest & Man-riding Systems

- Fall Arrest Davit Arms & Posts for Working at Height

- Sala Advanced Davit Arm Systems and Components

- Xtirpa Confined Space Davit Arm Systems and Components

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding & Rescue Tripods & Quadpods

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

- Home/

- Lifting Equipment/

- Chain Hoists; Manual, Electric, Air/

- Electric Chain Hoists/

- Donati Electric Chain Hoists/

- Donati DMK Electric Chain Hoist

Donati DMK Electric Chain Hoist

400v 3Ph 50Hz electric hoist with options for hook/eye suspension or manual, geared and electric trolleys. Single or dual speed lift/travel. 125kg to 4 tonne.

DMK / DDEC-4296

The Donati "DMK Series" Electric Chain hoists are produced according to the design of modular components, which when assembled together in relation to industrial and commercial needs allows a vast amount of standard and specialist executions to be carried out economically and rapidly.

A High level of Quality is guarenteed and checked by Donati's company quality control system according to UNI EN ISO 9001: 1994 Standards.

The Manufacturer uses the most advanced technology based on production processes and allows the putting together of totally reliable and technically innovative machines.

Configurations

The massive flexibility when applying the DMK Hoist allows 6 standard configuration options:

- Fixed Configuration: Eyebolt suspension as standard or hook-suspension on request

- Sold with eyebolt suspension

- More than 150 standard executions - 1 or 2 lifting speeds

- Capacities from 125 up to 4000 kgs.

- FEM (ISO) : 2M(M5)

- Standard hook runs 3 mts. (different lengths on request)

- High-strength steel rod chain 80kg/mm²

- Noise level less than 85 dB (A)

- Epicyclic crown wheel reduction gear and self-braking electrical motor with conical brake that ensures efficient braking action.

- Motor protection IP55, insulation class "F"

- Supply voltage : 400V- 3 phase - 50 Hz.

- Low voltage controls 48V

- Single chain fall (up to 2000 kgs.) with clutch device, dual chain falls (up to 4000 kgs.) with electromechanical overload device and raise/lower limit switches

- Hand-pushed (Manual push) Trolley: Recommended for light duty/short load travel only, Allows a horizontal push to move the load.

- Horizontal movement by push/pulling the load

- Recommended for light duty and short load travel only

- The push trolley is adjustable for variable flange widths, fitted with steel machined wheels, permanently self-lubricated bearings, fitted with anti tilt derailment bars and equiped with shock absorbing buffers.

- Capacities from 125 up to 4000 kgs.

- FEM (ISO) : 2M(M5)

- Working at one or two lifting speeds

- Other characteristics as per DMK in fixed execution

- Electrically operated (Motorised) Trolley: When manual load pushing is not feasable or is too heavy duty, the load can be moved electronically using the hoists' push-button panel.

- Movement operated by the push button panel fitted on the hoist

- Recommended when manual load pushing is not feasible and for heavy duty use.

- The electric trolley is adjustable for variable flange widths, fitted with steel machined wheels, permanently self-lubricated bearings, fitted with anti tilt derailment bars to prevent drop or derailing, and equipped with shock absorbing buffers.

- The trolley can be supplied at:

- 1 speed - m/min. 11 or 22

- 2 speeds - m/min. 7/22

- Electric limit switches to limit the horizontal travel of the electric trolley on the beam

- Suitable for rectilinear monorails; with special devices it can runs on curves (minimum internal radius on the technical catalogue)

- Capacities from 125 up to 4000 kgs.

- FEM (ISO) : 2M (M5)

- Other characteristics as per DMK in fixed execution

- Manual Gear operated Trolley: The operator controls the trolley by means of a chain that moves the wheels along the beam, advised for when load travel is short or a low number of cycles is needed.

- Low Headroom: The hoist is fitted to a frame with two trolleys (either Electrical or Manual) to get the maximum hook-run and comes with a return system for the chain.

- The best solution to get the maximum hook-run; fitted on a frame with a return system for the chain, the frame is mounted on 2 trolleys.

- Available in electric or hand-push execution

- Capacities from 125 up to 4000 kgs.

- FEM (ISO) : 2M(M5)

- Lifting and travelling at 1 or 2 speed

- Other characteristics as per DMK in fixed execution

- Climbing: This allows reaching to the installation point with the hook and related chain without having to lift the entire weight of the hoist, this is more suited to the entertainment industry, where frequent dismantling and installation of the hoist at great heights takes place.

- Allows the reaching of the installation point with the hook and the related chain, without having to lift the entire weight of the hoist.

- It is particularly suited to the entertainment industry and when frequent installation and dismatling at greater heights are requested.

- Capacities from 125 up to 2000 kgs.

- FEM (ISO) : 2M (M5)

- Lifting speed : mt/min. 4 or 8

- Chain box in cloth

- Other characteristics as per DMK in fixed execution

Electrical Power Supply

The DMK electric chain hoists are designed to be powered with alternate current with:

- Three-phase voltage of 400 V - 50 Hz. according to IEC 38-1.

- Single-phase voltage of 230 V +/- 5% - 50Hz. (for DMK hoists 1 - 2 - 3, at one speed and capacity up to 800 kg).

- Voltage and frequency different from standard are available on request.

Conditions of use in standard execution:

- Temperature of use: minimum - 10° C; maximum +40° C.

- Maximum relative humidity: 80%

- Maximum altitude 1000 m above sea level.

- The machine must be placed indoors, in a well-ventilated place free of corrosive vapours (acid vapours, saline mist, etc).

- Special executions, for different environmental conditions or for outdoor use are available on request.

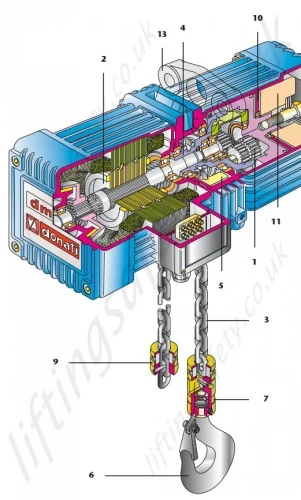

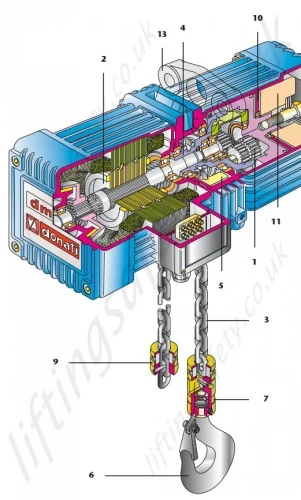

The Hoist In Detail

Please see the images to the right

1. Reduction Gear

Epicyclic crown wheel with heat-treated high-strength steel gearing supported by oil-bath lubricated ball bearings. Noise level at full load is less than 85 db. The aluminium casing is finned externally for more effective heat dissipation by radiation.

2. Self-braking electrical motor

The axial movement of the tapered brake ensures a fast braking action that remains reliable upon time accrual [RES. 4.1.2.1 c - Machinery Directive]. Brake lining is asbestos-free. The motor is available in two versions: a single polarity version for one-speed hoists, and a pole change version for two-speed hoists.

3. Chain

The chain is gauged and made of high-strength steel rod having an ultimate tensile strength of 80 kg/mm2, and ultimate elongation higher than 10%. The applicable safety coefficient is always better than 5 [RES. 4.1.2.4 - Machinery Directive]. The heat and galvanising treatments applied to the chain ensure high resistance to wear, aging and corrosion.

4. Load Sprocket

The load sprocket is heat treated, and has five pockets. The pockets are machined by use of recision machinery. The sprocket drives the chain, and ensures optimized chain motion.

5.Chain Guide (inserter/extractor)

This component provides for insertion and extraction of the chain links into and from the pockets of the load sprocket, both in ascent and descent. [RES. 4.1.2.6 - Machinery Directive].

6. Load Hook

The hook, made of high strength forged steel, is fitted with a safety device [RES. 4.1.2.6 - Machinery Directive], and rotates on a thrust bearing.

7. Single Fall Bottom Block(1 Chain Fall Hoists)

The bottom block is the joining element between the chain and the hook. It is made of steel, and is equipped with a heat-treated large cross-section chain locking pin.

8.Two Falls Hookblock(2 Chain Fall Hoists)

Made of aluminium, completely closed, it is equipped with a high-resistance steel transmission reel, thermally treated, with pockets for the housing of the chain.

9. Chain Stops

The stops are fitted on both the ascending and descending sections of the chain. They act as limit switches of hook travel [RES. 4.1.2.6 a - Machinery Directive], and can be set as desired. They are made of forged steel, and are fitted with a shock-absorbing insert.

10. Clutch Device

The clutch is an emergency device that replaces the traditional electrical limit switches as chain full up and down stops. It also operates as an overload protection [RES. 4.2.1.4 - Machinery Directive]. The clutch discs are asbestos-free, and are pre-loaded through a set of Belleville washers.

11. Balancer

The balancer is connected to the clutch joint, and provides for correct hoist balancing. It absorbs the heat generated during clutch operation.

12. New Brake DMK 2-3-4

The new brake shoe fitted in hoist sizes 2-3 and 4 is manufactured with a fan for more efficient cooling of the brake and motor. The high degree of inclination of the brake surface allows for optimal braking in the most arduous working conditions. Brake movement is simply carried out by the adjustment of the external brake ring.

13. Overload Device(2 Chain Fall Hoists)

Electromechanical, with a microswitch for one intervention threshold [RES. 4.2.1.4 - Enclosure I Machinery Directive ]. The overload device does not permit the hoist to be loaded with an overload exceeding 20% of its maximum capacity, by blocking the control circuit of the lifting control device.

14. Suspension

It is produced with an eyebolt suspension; are available on request, the executions with hook suspension or by eyebolt 90° version for longitudinal positioning of the hoist.

Lifting Limit Switches

Included in the supply for the 2 chain fall hoists and available, on request, for 1 chain fall hoists, they limit the hook’s ascent and descent run [RES. 4.1.2.6 a) - Enclosure 1 Machinery Directive]. They are made of two precision microswitches which function according to the principle of “slow positive opening” and work on the auxiliary circuit of the control device of the lifting motor.

Chain Box

The chain box is available in several sizes as a function of hook travel. It is made of shock-resistant plastics and is fitted with suspensions which ensure freedom of movement.

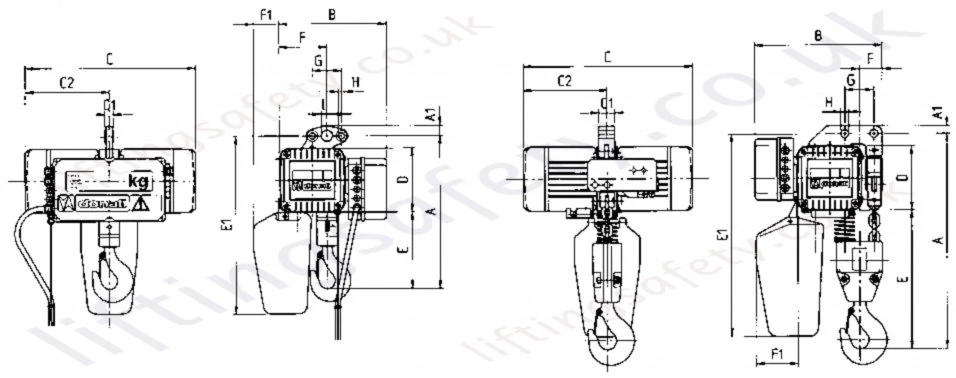

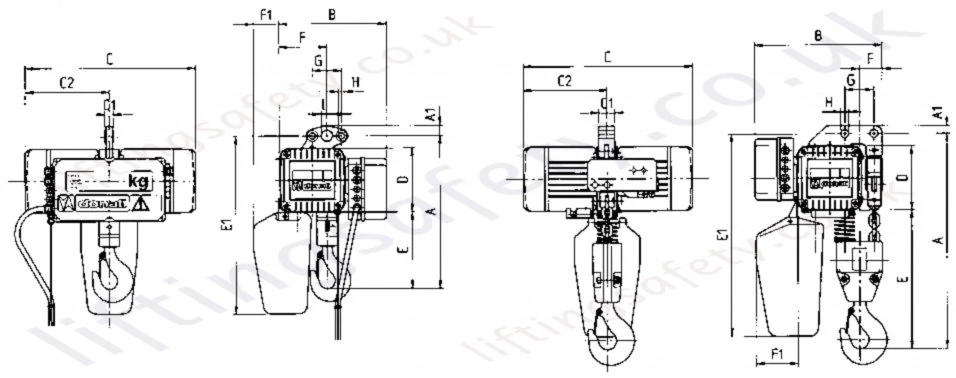

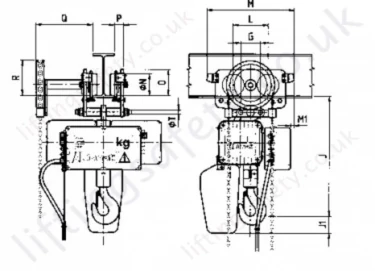

Eye Suspension Hoist

|

||||||||||||||||

| Capacity Max. (kg) | Size | Chain Falls | Type DMK | Hoist Weight (kg) | Overall Dimensions (mm) | |||||||||||

| A | A1 | B | C | C1 | C2 | D | E | F | G | H | I | |||||

| 125 | 1 | 1 | 154C | 23 | 285 | 23 | 253 | 355 | 19 | 177 | 120 | 138 | 80 | 70 | 14 | 27 |

| 125 | 132D/M | 23 | 285 | 23 | 253 | 355 | 19 | 177 | 120 | 138 | 80 | 70 | 14 | 27 | ||

| 250 | 134C | 23 | 285 | 23 | 253 | 355 | 19 | 177 | 120 | 138 | 80 | 70 | 14 | 27 | ||

| 250 | 112D/M | 23 | 285 | 23 | 253 | 355 | 19 | 177 | 120 | 138 | 80 | 70 | 14 | 27 | ||

| 125 | 2 | 232C | 33 | 320 | 23 | 268 | 438 | 19 | 237 | 135 | 160 | 92 | 70 | 14 | 27 | |

| 250 | 234C/M | 33 | 320 | 23 | 268 | 438 | 19 | 237 | 135 | 160 | 92 | 70 | 14 | 27 | ||

| 250 | 234D | 33 | 320 | 23 | 268 | 438 | 19 | 237 | 135 | 160 | 92 | 70 | 14 | 27 | ||

| 500 | 214C/M | 33 | 320 | 23 | 268 | 438 | 19 | 237 | 135 | 160 | 92 | 70 | 14 | 27 | ||

| 500 | 214D | 33 | 320 | 23 | 268 | 438 | 19 | 237 | 135 | 160 | 92 | 70 | 14 | 27 | ||

| 250 | 3 | 332C | 50 | 392 | 28 | 293 | 514 | 25 | 274 | 160 | 202 | 114 | 70 | 14 | 30 | |

| 500 | 334C/M | 50 | 392 | 28 | 293 | 514 | 25 | 274 | 160 | 202 | 114 | 70 | 14 | 30 | ||

| 500 | 334D | 50 | 392 | 28 | 293 | 514 | 25 | 274 | 160 | 202 | 114 | 70 | 14 | 30 | ||

| 1000 | 314C/M | 50 | 392 | 28 | 293 | 514 | 25 | 274 | 160 | 202 | 114 | 70 | 14 | 30 | ||

| 1000 | 314D | 50 | 392 | 28 | 293 | 514 | 25 | 274 | 160 | 202 | 114 | 70 | 14 | 30 | ||

| 500 | 4 | 432C | 80 | 483 | 32 | 332 | 583 | 27 | 317 | 200 | 245 | 146 | 70 | 20 | 35 | |

| 1000 | 434C | 80 | 483 | 32 | 332 | 583 | 27 | 317 | 200 | 245 | 146 | 90 | 20 | 35 | ||

| 1000 | 434D | 80 | 483 | 32 | 332 | 583 | 27 | 317 | 200 | 245 | 146 | 90 | 20 | 35 | ||

| 1600 | 424L | 80 | 483 | 32 | 332 | 583 | 27 | 317 | 200 | 245 | 146 | 90 | 20 | 35 | ||

| 2000 | 414C | 80 | 483 | 32 | 332 | 583 | 27 | 317 | 200 | 245 | 146 | 90 | 20 | 35 | ||

| 2000 | 414D | 105 | 483 | 32 | 332 | 583 | 27 | 317 | 200 | 245 | 146 | 90 | 20 | 35 | ||

| 3200 | 2 | 434L.I | 105 | 670 | 25 | 395 | 583 | 50 | 317 | 200 | 432 | 71 | 90 | 25 | - | |

| 3200 | 424D.I | 105 | 670 | 25 | 395 | 583 | 50 | 317 | 200 | 432 | 71 | 90 | 25 | - | ||

| 3200 | 434L.J | 105 | 670 | 25 | 395 | 583 | 50 | 317 | 200 | 432 | 71 | 90 | 25 | - | ||

| 3200 | 424D.J | 105 | 670 | 25 | 395 | 583 | 50 | 317 | 200 | 432 | 71 | 90 | 25 | - | ||

| 4000 | 424L.J | 105 | 670 | 25 | 395 | 583 | 50 | 317 | 200 | 432 | 71 | 90 | 25 | - | ||

| 4000 | 454D.J | 105 | 670 | 25 | 395 | 583 | 50 | 317 | 200 | 432 | 71 | 90 | 25 | - | ||

| 3200 | 424L.K | 105 | 670 | 25 | 395 | 583 | 50 | 317 | 200 | 432 | 71 | 90 | 25 | - | ||

| 3200 | 454D.K | 105 | 670 | 25 | 395 | 583 | 50 | 317 | 200 | 432 | 71 | 90 | 25 | - | ||

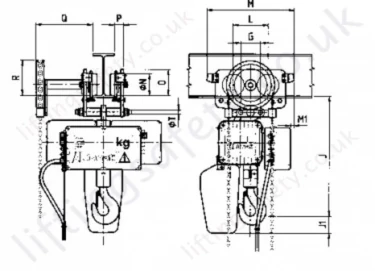

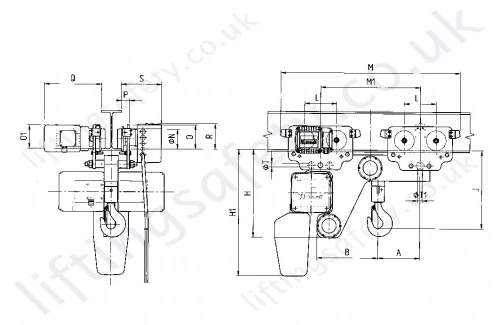

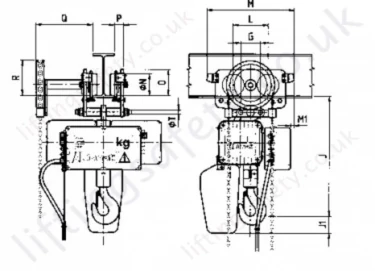

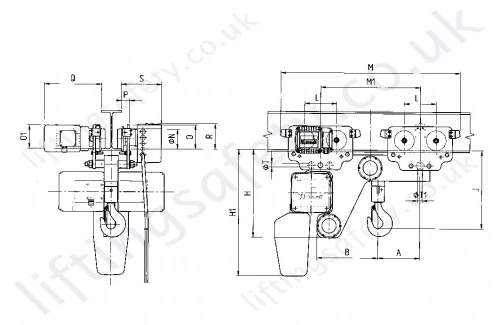

Trolley Suspension Hoist

|

|

||||||||||||||

| Push Travel Trolley (SM) | Geared Travel Trolley (CM) | ||||||||||||||

| DMK Size | Chain Falls | DMT Trolley Type | Hoist Trolley Weight (kg) | Overall Dimensions (mm) | |||||||||||

| J | L | M | M1 | ØN | O | O1 | P | Q | R | S | ØT | ||||

| 1 | 1 | SM2 | 29 | 340 | 100 | 236 | 54 | 52 | 72 | - | 20 | - | - | - | M16 |

| 1 | EM3 | 58 | 355 | 135 | 362 | -10 | 80 | 98 | 100(108) | 54 | 260(280) | 165 | 90 | M14 | |

| 1 | CM3 | 41 | 355 | 135 | 362 | -10 | 80 | 98 | - | 54 | 240 | 108 | - | M14 | |

| 2 | 1 | SM2 | 39 | 375 | 100 | 236 | 58 | 52 | 72 | - | 20 | - | - | - | M16 |

| 1 | EM3 | 68 | 390 | 135 | 362 | -6 | 80 | 98 | 100(108) | 54 | 260(280) | 165 | 90 | M14 | |

| 1 | CM3 | 51 | 390 | 135 | 362 | -6 | 80 | 98 | - | 54 | 240 | 108 | - | M14 | |

| 3 | 1 | SM3 | 62 | 456 | 135 | 362 | -3 | 80 | 98 | - | 54 | - | - | - | M14 |

| 1 | EM3 | 85 | 456 | 135 | 362 | -3 | 80 | 98 | 100(108) | 54 | 260(280) | 165 | 90 | M14 | |

| 1 | CM3 | 68 | 456 | 135 | 362 | -3 | 80 | 98 | - | 54 | 240 | 108 | - | M14 | |

| 4 | 1 | SM4 | 105 | 560 | 160 | 402 | -15 | 100 | 120 | - | 60 | - | - | - | M20 |

| 1 | EM4 | 130 | 560 | 160 | 402 | -15 | 100 | 120 | 110(118) | 60 | 266(286) | 165 | 96 | M20 | |

| 1 | CM4 | 115 | 560 | 160 | 402 | -15 | 100 | 120 | - | 60 | 264 | 160 | - | M20 | |

| 2 | SM5 | 160 | 755 | 201 | 510 | 70 | 125 | 155 | - | 55 | - | - | - | M24 | |

| 2 | EM5 | 190 | 755 | 201 | 510 | 70 | 125 | 155 | 130(130) | 55 | 295(295) | 208 | 110 | M24 | |

| 2 | CM5 | 170 | 755 | 201 | 510 | 70 | 125 | 155 | - | 55 | 340 | 198 | - | M24 | |

|

|||||||||||||||

| Motorised (Electric) Travel Trolley (EM) | |||||||||||||||

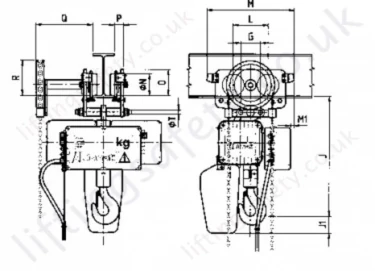

Low Headroom Trolley Suspended Hoist

|

||||||||||||||||||||

| Low Headroom Motorised Travel Trolley | ||||||||||||||||||||

| DMK Size | Capacity Max. (kg) | DMT Trolley Type | Hoist Trolley Weight (kg) | Overall Dimensions | ||||||||||||||||

| A | B | H | H1 | J | L | M | M1 | ØN | O | O1 | P | Q | R | S | ØT | ØT1 | ||||

| 1 | 250 | SM3+SM3 | 60 | 170 | 228 | 295 | 417 | 240 | 135 | 742 | 380 | 80 | 98 | - | 54 | - | 108 | - | M14 | M16 |

| SM3+EM3 | 75 | 170 | 228 | 295 | 417 | 240 | 135 | 742 | 380 | 80 | 98 | 100(108) | 54 | 260(280) | 108 | 160 | M14 | M16 | ||

| 2 | 500 | SM3+SM3 | 67 | 176 | 240 | 315 | 455 | 265 | 135 | 762 | 400 | 80 | 98 | - | 54 | - | 108 | - | M14 | M16 |

| SM3+EM3 | 80 | 176 | 240 | 315 | 455 | 265 | 135 | 762 | 400 | 80 | 98 | 100(108) | 54 | 260(280) | 108 | 160 | M14 | M16 | ||

| 3 | 1000 | SM3+SM3 | 100 | 190 | 275 | 365 | 510 | 327 | 135 | 812 | 450 | 80 | 98 | - | 54 | - | 108 | - | M14 | M16 |

| SM3+EM3 | 115 | 190 | 275 | 365 | 510 | 327 | 135 | 812 | 450 | 80 | 98 | 100(108) | 54 | 260(280) | 108 | 160 | M14 | M16 | ||

| 4 | 2000 | SM4+SM4 | 155 | 205 | 310 | 440 | 637 | 400 | 160 | 902 | 500 | 100 | 120 | - | 60 | - | 118 | - | M20 | M24 |

| SM4+EM4 | 170 | 205 | 310 | 440 | 637 | 400 | 160 | 902 | 500 | 100 | 120 | 110(118) | 60 | 266(286) | 118 | 170 | M20 | M24 | ||

| 4000 | on request | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

| on request | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | ||

Pricing

The Donati "DMK Series" Electric Chain hoists are produced according to the design of modular components, which when assembled together in relation to industrial and commercial needs allows a vast amount of standard and specialist executions to be carried out economically and rapidly.

A High level of Quality is guarenteed and checked by Donati's company quality control system according to UNI EN ISO 9001: 1994 Standards.

The Manufacturer uses the most advanced technology based on production processes and allows the putting together of totally reliable and technically innovative machines.

Configurations

The massive flexibility when applying the DMK Hoist allows 6 standard configuration options:

- Fixed Configuration: Eyebolt suspension as standard or hook-suspension on request

- Sold with eyebolt suspension

- More than 150 standard executions - 1 or 2 lifting speeds

- Capacities from 125 up to 4000 kgs.

- FEM (ISO) : 2M(M5)

- Standard hook runs 3 mts. (different lengths on request)

- High-strength steel rod chain 80kg/mm²

- Noise level less than 85 dB (A)

- Epicyclic crown wheel reduction gear and self-braking electrical motor with conical brake that ensures efficient braking action.

- Motor protection IP55, insulation class "F"

- Supply voltage : 400V- 3 phase - 50 Hz.

- Low voltage controls 48V

- Single chain fall (up to 2000 kgs.) with clutch device, dual chain falls (up to 4000 kgs.) with electromechanical overload device and raise/lower limit switches

- Hand-pushed (Manual push) Trolley: Recommended for light duty/short load travel only, Allows a horizontal push to move the load.

- Horizontal movement by push/pulling the load

- Recommended for light duty and short load travel only

- The push trolley is adjustable for variable flange widths, fitted with steel machined wheels, permanently self-lubricated bearings, fitted with anti tilt derailment bars and equiped with shock absorbing buffers.

- Capacities from 125 up to 4000 kgs.

- FEM (ISO) : 2M(M5)

- Working at one or two lifting speeds

- Other characteristics as per DMK in fixed execution

- Electrically operated (Motorised) Trolley: When manual load pushing is not feasable or is too heavy duty, the load can be moved electronically using the hoists' push-button panel.

- Movement operated by the push button panel fitted on the hoist

- Recommended when manual load pushing is not feasible and for heavy duty use.

- The electric trolley is adjustable for variable flange widths, fitted with steel machined wheels, permanently self-lubricated bearings, fitted with anti tilt derailment bars to prevent drop or derailing, and equipped with shock absorbing buffers.

- The trolley can be supplied at:

- 1 speed - m/min. 11 or 22

- 2 speeds - m/min. 7/22

- Electric limit switches to limit the horizontal travel of the electric trolley on the beam

- Suitable for rectilinear monorails; with special devices it can runs on curves (minimum internal radius on the technical catalogue)

- Capacities from 125 up to 4000 kgs.

- FEM (ISO) : 2M (M5)

- Other characteristics as per DMK in fixed execution

- Manual Gear operated Trolley: The operator controls the trolley by means of a chain that moves the wheels along the beam, advised for when load travel is short or a low number of cycles is needed.

- Low Headroom: The hoist is fitted to a frame with two trolleys (either Electrical or Manual) to get the maximum hook-run and comes with a return system for the chain.

- The best solution to get the maximum hook-run; fitted on a frame with a return system for the chain, the frame is mounted on 2 trolleys.

- Available in electric or hand-push execution

- Capacities from 125 up to 4000 kgs.

- FEM (ISO) : 2M(M5)

- Lifting and travelling at 1 or 2 speed

- Other characteristics as per DMK in fixed execution

- Climbing: This allows reaching to the installation point with the hook and related chain without having to lift the entire weight of the hoist, this is more suited to the entertainment industry, where frequent dismantling and installation of the hoist at great heights takes place.

- Allows the reaching of the installation point with the hook and the related chain, without having to lift the entire weight of the hoist.

- It is particularly suited to the entertainment industry and when frequent installation and dismatling at greater heights are requested.

- Capacities from 125 up to 2000 kgs.

- FEM (ISO) : 2M (M5)

- Lifting speed : mt/min. 4 or 8

- Chain box in cloth

- Other characteristics as per DMK in fixed execution

Electrical Power Supply

The DMK electric chain hoists are designed to be powered with alternate current with:

- Three-phase voltage of 400 V - 50 Hz. according to IEC 38-1.

- Single-phase voltage of 230 V +/- 5% - 50Hz. (for DMK hoists 1 - 2 - 3, at one speed and capacity up to 800 kg).

- Voltage and frequency different from standard are available on request.

Conditions of use in standard execution:

- Temperature of use: minimum - 10° C; maximum +40° C.

- Maximum relative humidity: 80%

- Maximum altitude 1000 m above sea level.

- The machine must be placed indoors, in a well-ventilated place free of corrosive vapours (acid vapours, saline mist, etc).

- Special executions, for different environmental conditions or for outdoor use are available on request.

The Hoist In Detail

Please see the images to the right

1. Reduction Gear

Epicyclic crown wheel with heat-treated high-strength steel gearing supported by oil-bath lubricated ball bearings. Noise level at full load is less than 85 db. The aluminium casing is finned externally for more effective heat dissipation by radiation.

2. Self-braking electrical motor

The axial movement of the tapered brake ensures a fast braking action that remains reliable upon time accrual [RES. 4.1.2.1 c - Machinery Directive]. Brake lining is asbestos-free. The motor is available in two versions: a single polarity version for one-speed hoists, and a pole change version for two-speed hoists.

3. Chain

The chain is gauged and made of high-strength steel rod having an ultimate tensile strength of 80 kg/mm2, and ultimate elongation higher than 10%. The applicable safety coefficient is always better than 5 [RES. 4.1.2.4 - Machinery Directive]. The heat and galvanising treatments applied to the chain ensure high resistance to wear, aging and corrosion.

4. Load Sprocket

The load sprocket is heat treated, and has five pockets. The pockets are machined by use of recision machinery. The sprocket drives the chain, and ensures optimized chain motion.

5.Chain Guide (inserter/extractor)

This component provides for insertion and extraction of the chain links into and from the pockets of the load sprocket, both in ascent and descent. [RES. 4.1.2.6 - Machinery Directive].

6. Load Hook

The hook, made of high strength forged steel, is fitted with a safety device [RES. 4.1.2.6 - Machinery Directive], and rotates on a thrust bearing.

7. Single Fall Bottom Block(1 Chain Fall Hoists)

The bottom block is the joining element between the chain and the hook. It is made of steel, and is equipped with a heat-treated large cross-section chain locking pin.

8.Two Falls Hookblock(2 Chain Fall Hoists)

Made of aluminium, completely closed, it is equipped with a high-resistance steel transmission reel, thermally treated, with pockets for the housing of the chain.

9. Chain Stops

The stops are fitted on both the ascending and descending sections of the chain. They act as limit switches of hook travel [RES. 4.1.2.6 a - Machinery Directive], and can be set as desired. They are made of forged steel, and are fitted with a shock-absorbing insert.

10. Clutch Device

The clutch is an emergency device that replaces the traditional electrical limit switches as chain full up and down stops. It also operates as an overload protection [RES. 4.2.1.4 - Machinery Directive]. The clutch discs are asbestos-free, and are pre-loaded through a set of Belleville washers.

11. Balancer

The balancer is connected to the clutch joint, and provides for correct hoist balancing. It absorbs the heat generated during clutch operation.

12. New Brake DMK 2-3-4

The new brake shoe fitted in hoist sizes 2-3 and 4 is manufactured with a fan for more efficient cooling of the brake and motor. The high degree of inclination of the brake surface allows for optimal braking in the most arduous working conditions. Brake movement is simply carried out by the adjustment of the external brake ring.

13. Overload Device(2 Chain Fall Hoists)

Electromechanical, with a microswitch for one intervention threshold [RES. 4.2.1.4 - Enclosure I Machinery Directive ]. The overload device does not permit the hoist to be loaded with an overload exceeding 20% of its maximum capacity, by blocking the control circuit of the lifting control device.

14. Suspension

It is produced with an eyebolt suspension; are available on request, the executions with hook suspension or by eyebolt 90° version for longitudinal positioning of the hoist.

Lifting Limit Switches

Included in the supply for the 2 chain fall hoists and available, on request, for 1 chain fall hoists, they limit the hook’s ascent and descent run [RES. 4.1.2.6 a) - Enclosure 1 Machinery Directive]. They are made of two precision microswitches which function according to the principle of “slow positive opening” and work on the auxiliary circuit of the control device of the lifting motor.

Chain Box

The chain box is available in several sizes as a function of hook travel. It is made of shock-resistant plastics and is fitted with suspensions which ensure freedom of movement.

Eye Suspension Hoist

|

||||||||||||||||

| Capacity Max. (kg) | Size | Chain Falls | Type DMK | Hoist Weight (kg) | Overall Dimensions (mm) | |||||||||||

| A | A1 | B | C | C1 | C2 | D | E | F | G | H | I | |||||

| 125 | 1 | 1 | 154C | 23 | 285 | 23 | 253 | 355 | 19 | 177 | 120 | 138 | 80 | 70 | 14 | 27 |

| 125 | 132D/M | 23 | 285 | 23 | 253 | 355 | 19 | 177 | 120 | 138 | 80 | 70 | 14 | 27 | ||

| 250 | 134C | 23 | 285 | 23 | 253 | 355 | 19 | 177 | 120 | 138 | 80 | 70 | 14 | 27 | ||

| 250 | 112D/M | 23 | 285 | 23 | 253 | 355 | 19 | 177 | 120 | 138 | 80 | 70 | 14 | 27 | ||

| 125 | 2 | 232C | 33 | 320 | 23 | 268 | 438 | 19 | 237 | 135 | 160 | 92 | 70 | 14 | 27 | |

| 250 | 234C/M | 33 | 320 | 23 | 268 | 438 | 19 | 237 | 135 | 160 | 92 | 70 | 14 | 27 | ||

| 250 | 234D | 33 | 320 | 23 | 268 | 438 | 19 | 237 | 135 | 160 | 92 | 70 | 14 | 27 | ||

| 500 | 214C/M | 33 | 320 | 23 | 268 | 438 | 19 | 237 | 135 | 160 | 92 | 70 | 14 | 27 | ||

| 500 | 214D | 33 | 320 | 23 | 268 | 438 | 19 | 237 | 135 | 160 | 92 | 70 | 14 | 27 | ||

| 250 | 3 | 332C | 50 | 392 | 28 | 293 | 514 | 25 | 274 | 160 | 202 | 114 | 70 | 14 | 30 | |

| 500 | 334C/M | 50 | 392 | 28 | 293 | 514 | 25 | 274 | 160 | 202 | 114 | 70 | 14 | 30 | ||

| 500 | 334D | 50 | 392 | 28 | 293 | 514 | 25 | 274 | 160 | 202 | 114 | 70 | 14 | 30 | ||

| 1000 | 314C/M | 50 | 392 | 28 | 293 | 514 | 25 | 274 | 160 | 202 | 114 | 70 | 14 | 30 | ||

| 1000 | 314D | 50 | 392 | 28 | 293 | 514 | 25 | 274 | 160 | 202 | 114 | 70 | 14 | 30 | ||

| 500 | 4 | 432C | 80 | 483 | 32 | 332 | 583 | 27 | 317 | 200 | 245 | 146 | 70 | 20 | 35 | |

| 1000 | 434C | 80 | 483 | 32 | 332 | 583 | 27 | 317 | 200 | 245 | 146 | 90 | 20 | 35 | ||

| 1000 | 434D | 80 | 483 | 32 | 332 | 583 | 27 | 317 | 200 | 245 | 146 | 90 | 20 | 35 | ||

| 1600 | 424L | 80 | 483 | 32 | 332 | 583 | 27 | 317 | 200 | 245 | 146 | 90 | 20 | 35 | ||

| 2000 | 414C | 80 | 483 | 32 | 332 | 583 | 27 | 317 | 200 | 245 | 146 | 90 | 20 | 35 | ||

| 2000 | 414D | 105 | 483 | 32 | 332 | 583 | 27 | 317 | 200 | 245 | 146 | 90 | 20 | 35 | ||

| 3200 | 2 | 434L.I | 105 | 670 | 25 | 395 | 583 | 50 | 317 | 200 | 432 | 71 | 90 | 25 | - | |

| 3200 | 424D.I | 105 | 670 | 25 | 395 | 583 | 50 | 317 | 200 | 432 | 71 | 90 | 25 | - | ||

| 3200 | 434L.J | 105 | 670 | 25 | 395 | 583 | 50 | 317 | 200 | 432 | 71 | 90 | 25 | - | ||

| 3200 | 424D.J | 105 | 670 | 25 | 395 | 583 | 50 | 317 | 200 | 432 | 71 | 90 | 25 | - | ||

| 4000 | 424L.J | 105 | 670 | 25 | 395 | 583 | 50 | 317 | 200 | 432 | 71 | 90 | 25 | - | ||

| 4000 | 454D.J | 105 | 670 | 25 | 395 | 583 | 50 | 317 | 200 | 432 | 71 | 90 | 25 | - | ||

| 3200 | 424L.K | 105 | 670 | 25 | 395 | 583 | 50 | 317 | 200 | 432 | 71 | 90 | 25 | - | ||

| 3200 | 454D.K | 105 | 670 | 25 | 395 | 583 | 50 | 317 | 200 | 432 | 71 | 90 | 25 | - | ||

Trolley Suspension Hoist

|

|

||||||||||||||

| Push Travel Trolley (SM) | Geared Travel Trolley (CM) | ||||||||||||||

| DMK Size | Chain Falls | DMT Trolley Type | Hoist Trolley Weight (kg) | Overall Dimensions (mm) | |||||||||||

| J | L | M | M1 | ØN | O | O1 | P | Q | R | S | ØT | ||||

| 1 | 1 | SM2 | 29 | 340 | 100 | 236 | 54 | 52 | 72 | - | 20 | - | - | - | M16 |

| 1 | EM3 | 58 | 355 | 135 | 362 | -10 | 80 | 98 | 100(108) | 54 | 260(280) | 165 | 90 | M14 | |

| 1 | CM3 | 41 | 355 | 135 | 362 | -10 | 80 | 98 | - | 54 | 240 | 108 | - | M14 | |

| 2 | 1 | SM2 | 39 | 375 | 100 | 236 | 58 | 52 | 72 | - | 20 | - | - | - | M16 |

| 1 | EM3 | 68 | 390 | 135 | 362 | -6 | 80 | 98 | 100(108) | 54 | 260(280) | 165 | 90 | M14 | |

| 1 | CM3 | 51 | 390 | 135 | 362 | -6 | 80 | 98 | - | 54 | 240 | 108 | - | M14 | |

| 3 | 1 | SM3 | 62 | 456 | 135 | 362 | -3 | 80 | 98 | - | 54 | - | - | - | M14 |

| 1 | EM3 | 85 | 456 | 135 | 362 | -3 | 80 | 98 | 100(108) | 54 | 260(280) | 165 | 90 | M14 | |

| 1 | CM3 | 68 | 456 | 135 | 362 | -3 | 80 | 98 | - | 54 | 240 | 108 | - | M14 | |

| 4 | 1 | SM4 | 105 | 560 | 160 | 402 | -15 | 100 | 120 | - | 60 | - | - | - | M20 |

| 1 | EM4 | 130 | 560 | 160 | 402 | -15 | 100 | 120 | 110(118) | 60 | 266(286) | 165 | 96 | M20 | |

| 1 | CM4 | 115 | 560 | 160 | 402 | -15 | 100 | 120 | - | 60 | 264 | 160 | - | M20 | |

| 2 | SM5 | 160 | 755 | 201 | 510 | 70 | 125 | 155 | - | 55 | - | - | - | M24 | |

| 2 | EM5 | 190 | 755 | 201 | 510 | 70 | 125 | 155 | 130(130) | 55 | 295(295) | 208 | 110 | M24 | |

| 2 | CM5 | 170 | 755 | 201 | 510 | 70 | 125 | 155 | - | 55 | 340 | 198 | - | M24 | |

|

|||||||||||||||

| Motorised (Electric) Travel Trolley (EM) | |||||||||||||||

Low Headroom Trolley Suspended Hoist

|

||||||||||||||||||||

| Low Headroom Motorised Travel Trolley | ||||||||||||||||||||

| DMK Size | Capacity Max. (kg) | DMT Trolley Type | Hoist Trolley Weight (kg) | Overall Dimensions | ||||||||||||||||

| A | B | H | H1 | J | L | M | M1 | ØN | O | O1 | P | Q | R | S | ØT | ØT1 | ||||

| 1 | 250 | SM3+SM3 | 60 | 170 | 228 | 295 | 417 | 240 | 135 | 742 | 380 | 80 | 98 | - | 54 | - | 108 | - | M14 | M16 |

| SM3+EM3 | 75 | 170 | 228 | 295 | 417 | 240 | 135 | 742 | 380 | 80 | 98 | 100(108) | 54 | 260(280) | 108 | 160 | M14 | M16 | ||

| 2 | 500 | SM3+SM3 | 67 | 176 | 240 | 315 | 455 | 265 | 135 | 762 | 400 | 80 | 98 | - | 54 | - | 108 | - | M14 | M16 |

| SM3+EM3 | 80 | 176 | 240 | 315 | 455 | 265 | 135 | 762 | 400 | 80 | 98 | 100(108) | 54 | 260(280) | 108 | 160 | M14 | M16 | ||

| 3 | 1000 | SM3+SM3 | 100 | 190 | 275 | 365 | 510 | 327 | 135 | 812 | 450 | 80 | 98 | - | 54 | - | 108 | - | M14 | M16 |

| SM3+EM3 | 115 | 190 | 275 | 365 | 510 | 327 | 135 | 812 | 450 | 80 | 98 | 100(108) | 54 | 260(280) | 108 | 160 | M14 | M16 | ||

| 4 | 2000 | SM4+SM4 | 155 | 205 | 310 | 440 | 637 | 400 | 160 | 902 | 500 | 100 | 120 | - | 60 | - | 118 | - | M20 | M24 |

| SM4+EM4 | 170 | 205 | 310 | 440 | 637 | 400 | 160 | 902 | 500 | 100 | 120 | 110(118) | 60 | 266(286) | 118 | 170 | M20 | M24 | ||

| 4000 | on request | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | |

| on request | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | ||

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.