-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Fibre Lifting Slings

- Chain Slings & Components

- Lifting and Lashing Chain

- Wire Rope Slings & Assemblies

- Shackles

- Eye Bolts and Eye Nuts

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Runway Beam Monorail Crane Trolleys, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms and Jib Cranes

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

- Man-riding Hoists & Rescue Winches

-

Fall Arrest & Man-riding Systems

- Fall Arrest Davit Arms & Posts for Working at Height

- Sala Advanced Davit Arm Systems and Components

- Xtirpa Confined Space Davit Arm Systems and Components

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding & Rescue Tripods & Quadpods

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

Tiger Lifting "SS11" Sub-sea (Underwater) Ultra Safe Lever Hoist - Range from 800kg to 20 tonnes

SS11 / TLSU-4008

Unfortunately this product is no longer available and has been superseded by the Tiger "SS19" Sub-sea (Underwater) Ultra Safe Lever Hoist. Alternatively Contact Us with your requirements.

The SS11 (formerly known as the Tigershark) has been designed and developed over a number of years for use primarily in the Subsea environment. The design and anti-corrosion features incorporated in the SS11 hoist range give it significant safety advantages over standard lever hoists, making the hoist the ideal tool for all Marine and extreme applications. Range from 800kg – 20000kg

Developed initially with the goal of giving key stakeholders within the Oil and Gas Industry a hoist that could be certified for safe use Subsea whilst meeting all the requirements of IMCA DO28 Rev. 1 "Guidance notes for offshore lever hoists" the SS11 meets and exceeds these requirements, as well as conforming to standards such as BS EN 13157:2004 and ASME B30.21-2005.

With over 50 years of professional manufacturing experience Tiger’s commitment to innovation and customer satisfaction mean we will continue to develop and improve our products by communicating and working with our customers. The SS11 range of Subsea lever hoists is evidence of this practice.

An atex certified version of the SS11 Lever Hoist is also available.

Main Features

- *NEW* Twin Cam shaped pawl design

- Proven track record

- Double switch brake mechanism

- Marine specific friction discs

- Meets and exceeds IMCA DO28 Rev 1 guidance notes for offshore lever hoists

- Light load protection at 2% of the rated capacity

- Anti-corrosive protection to ensure reliable long term use

- *NEW* external corrosion protection

- Adaptable to use both inverted and horizontally

- Brake chamber protection from outside contamination

- High performance premium grease

- Stainless steel fixings and fasteners

- -40°C to +50°C Operating temperature range

- *NEW* adjustable chain end anchorage

- Can be supplied with Various Top and Bottom fitting to suit your needs, see the 'Adaptor Fittings' tab above for further information.

Double Brake

The SS11 comes with a unique dual brake mechanism that automatically engages when the lever hoist feels the slightest resistance on the bottom hook. This key feature means that the SS11 will raise, hold and lower the lightest of loads without slipping. The two stage process protects against accidental light load failures by putting the hoist into neutral whilst under load.

Light Load Protection

The unique brake system designed for the SS11 guarantees a light load protection at 2% of the rated capacity.

Cam Type Brake Pawls

This latest development in brake efficiency guarantees permanent engagement of at least one of the twin reciprocating cam pawls fitted to the SS11, ensuring the pawl only just clears the ratchet wheel, with the minimum of clearance as required under BS 4898:1973. But most importantly, in the unlikely event of a pawl spring failure, this new design will ensure the brake is still fully functional and the load is sustained without damage to the mechanism.

Anti-Corrosion Protection

Critical internal components are protected by our OCP (Organic Compound Protection) finish giving unprecedented long term reliability. OCP has been proven to be effective through 1000 hours of the ASTM B117 Salt Spray Test. The SS11 is NOW externally finished with our own anti-corrosion finish giving the SS11 body over 1000 hours of protection under the same test criteria, whilst maintaining a high degree of impact protection.

Marine Friction Discs

Developed and designed for Subsea use creating a highly efficient, reliable braking surface for use in the most extreme conditions.

Brake Chamber Protection

Precisely engineered side plates and components are protected by a full gasket giving the SS11 brake chamber and contents maximum protection from external contamination.

Chain Guide

Specifically designed to guide the load chain safely onto or off the load sheave without snagging or jamming, the fluted chain stripper allows the safe use of the SS11 when used in any orientation.

Load Protection

Security of the load is achieved by full engagement of the heavy duty spring latch into the recessed nose of the hook safeguarding the load when side loading of the latch occurs.

High Performance Premium Grease

Load carrying ability, mechanical stability, corrosion protection, water resistance and increased operating temperature ranges are all improved by the using only the very best lubricant.

Overload protection

Designed for maximum safety, comfort, efficiency and ease of use, the operator friendly Hammerhead handle prevents the use of unauthorised extension bars overloading the SS11

Hooks

Drop forged and heat treated alloy hooks are furnished with heavy duty latch kits that fully engage into the nose of the hook offering maximum load security. The swivel hooks are attached to the yoke using high grade nuts & bolts allowing for complete inspection during any statutory inspection or written scheme maintenance. Recessed forgings offer full protection to the load chain anchor bolts on all our bottom hooks.

Chain end anchorage

Tiger have incorporated the ultimate safeguarding of a single point failure mode as described in IMCA DO28 Rev. 1 Note 7.2 by installing a new specially designed adjustable chain end stop profiled to fit the contours of the hoist body. This offers complete assurance to the operator, whilst maintaining the flexibility of “freewheeling” the chain to any required starting position.

Performance

The SS11 lever hoist has undergone a full test program that includes:

Type Testing

- Ultimate strength test, at least 4 times the Working load limit (WLL)

- Chain end anchorage test, passing at least 4 times the WLL without any restriction of the brake or gears

Test on every hoist

- Proof loading at 1.5 times the rated capacity

- Light load testing at maximum of 2% rated capacity

Salt Spray – Submersion Test Programme

The SS11 range of hoists has successfully been type tested to over 700 hours continuous exposure to an industry generated test programme that was specifically drawn up and agreed upon by a group of independent professionals incorporating ASTM B117 environmental conditions. This programme included over 50 individual load tests on the same hoist of varying weights at various timescales, to fully challenge the SS11.

Specifications

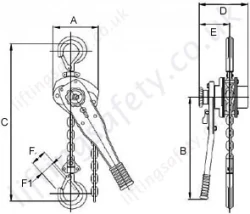

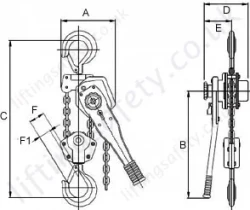

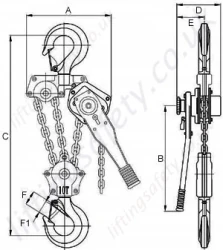

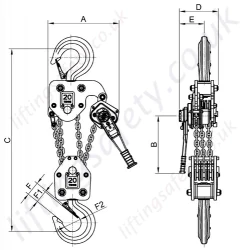

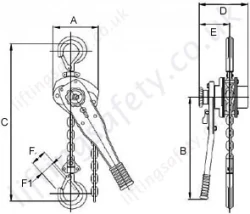

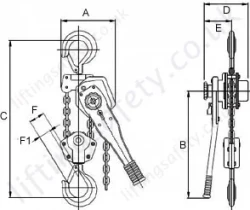

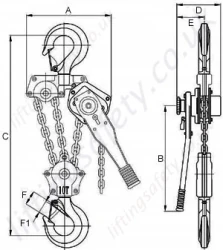

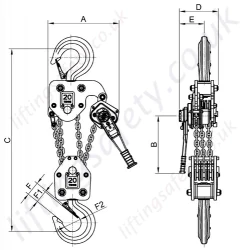

| Product Code | Capacity (tonne) | Effort (kg) | Effort (kg) with ext’n handle | Dimensions (mm) | Load Chain | Standard HOL (m) | Mass Kg @ std HOL | |||||||

| A | B | C | D | E | F | F1 | Diameter (mm) | No. of falls | ||||||

| SS-0080 | 0.8 | 23 | - | 128 | 240 | 275 | 158 | 99 | 30 | 28 | Ø6.3 | 1 | 3.0 | 9.1 |

| SS-0150 | 1.5 | 26 | - | 154 | 360 | 320 | 172 | 104 | 38 | 34 | Ø7.1 | 1 | 3.0 | 12.6 |

| SS-0300 | 3.0 | 38 | 22 | 182 | 360 | 400 | 195 | 108 | 43 | 35 | Ø10.0 | 1 | 3.0 | 22.0 |

| SS-0600 | 6.0 | 40 | 23.5 | 242 | 360 | 570 | 195 | 108 | 57 | 50 | Ø10.0 | 2 | 3.0 | 36.5 |

| SS-1000 | 10.0 | 47 | 27.5 | 370 | 360 | 630 | 195 | 108 | 71 | 54 | Ø10.0 | 3 | 3.0 | 56.3 |

| SS-2000 | 20.0 | 43 | - | 470 | 370 | 1050 | 251 | 161 | 90 | 70 | Ø10.0 | 6 | 3 | 174.0 |

Dimensional Images

|

|

|

|

| 800kg to 3000kg | 6000kg | 10000kg | 20000kg |

Tiger Adaptor Hoists are available with a drop-forged clevis adaptor allowing for the interchangeable range of EN1677 Tiger grade 100 clevis fittings.

This Tiger manufactured knuckle configuration gives 360° Rotation and 180° Pivot for maximum flexibility, whilst maintaining our 4:1 factor of safety at all angles.

- Available for Tiger TCB14 / SS12 chain blocks and PROLH / SS11 / TLH lever hoists.

- All fittings meet the standards of EN1677 grade 100 at 400°C tempering.

- Drop forged adaptor for maximum strength certified 4:1 FOS at all angles.

- Self-locking (safety) hook, clevis shackle, reevable egg (master) link or sling hook fitting available.

- Overload protection available.

- For lifting at angles (cross hauling/fleeting/drifting) with no deration.

- Chain Blocks – 500kg – 10t capacity.

- Lever Hoists – 800kg – 10t capacity.

Adaptor Sling Hook

Safety Hooks

Reevable Egg Link

Hoist Clevis Shackle

Adaptor Roation

Pricing

Unfortunately this product has been discontinued and/or is no longer available. Please contact us for details on possible alternative products.

Unfortunately this product is no longer available and has been superseded by the Tiger "SS19" Sub-sea (Underwater) Ultra Safe Lever Hoist. Alternatively Contact Us with your requirements.

The SS11 (formerly known as the Tigershark) has been designed and developed over a number of years for use primarily in the Subsea environment. The design and anti-corrosion features incorporated in the SS11 hoist range give it significant safety advantages over standard lever hoists, making the hoist the ideal tool for all Marine and extreme applications. Range from 800kg – 20000kg

Developed initially with the goal of giving key stakeholders within the Oil and Gas Industry a hoist that could be certified for safe use Subsea whilst meeting all the requirements of IMCA DO28 Rev. 1 "Guidance notes for offshore lever hoists" the SS11 meets and exceeds these requirements, as well as conforming to standards such as BS EN 13157:2004 and ASME B30.21-2005.

With over 50 years of professional manufacturing experience Tiger’s commitment to innovation and customer satisfaction mean we will continue to develop and improve our products by communicating and working with our customers. The SS11 range of Subsea lever hoists is evidence of this practice.

An atex certified version of the SS11 Lever Hoist is also available.

Main Features

- *NEW* Twin Cam shaped pawl design

- Proven track record

- Double switch brake mechanism

- Marine specific friction discs

- Meets and exceeds IMCA DO28 Rev 1 guidance notes for offshore lever hoists

- Light load protection at 2% of the rated capacity

- Anti-corrosive protection to ensure reliable long term use

- *NEW* external corrosion protection

- Adaptable to use both inverted and horizontally

- Brake chamber protection from outside contamination

- High performance premium grease

- Stainless steel fixings and fasteners

- -40°C to +50°C Operating temperature range

- *NEW* adjustable chain end anchorage

- Can be supplied with Various Top and Bottom fitting to suit your needs, see the 'Adaptor Fittings' tab above for further information.

Double Brake

The SS11 comes with a unique dual brake mechanism that automatically engages when the lever hoist feels the slightest resistance on the bottom hook. This key feature means that the SS11 will raise, hold and lower the lightest of loads without slipping. The two stage process protects against accidental light load failures by putting the hoist into neutral whilst under load.

Light Load Protection

The unique brake system designed for the SS11 guarantees a light load protection at 2% of the rated capacity.

Cam Type Brake Pawls

This latest development in brake efficiency guarantees permanent engagement of at least one of the twin reciprocating cam pawls fitted to the SS11, ensuring the pawl only just clears the ratchet wheel, with the minimum of clearance as required under BS 4898:1973. But most importantly, in the unlikely event of a pawl spring failure, this new design will ensure the brake is still fully functional and the load is sustained without damage to the mechanism.

Anti-Corrosion Protection

Critical internal components are protected by our OCP (Organic Compound Protection) finish giving unprecedented long term reliability. OCP has been proven to be effective through 1000 hours of the ASTM B117 Salt Spray Test. The SS11 is NOW externally finished with our own anti-corrosion finish giving the SS11 body over 1000 hours of protection under the same test criteria, whilst maintaining a high degree of impact protection.

Marine Friction Discs

Developed and designed for Subsea use creating a highly efficient, reliable braking surface for use in the most extreme conditions.

Brake Chamber Protection

Precisely engineered side plates and components are protected by a full gasket giving the SS11 brake chamber and contents maximum protection from external contamination.

Chain Guide

Specifically designed to guide the load chain safely onto or off the load sheave without snagging or jamming, the fluted chain stripper allows the safe use of the SS11 when used in any orientation.

Load Protection

Security of the load is achieved by full engagement of the heavy duty spring latch into the recessed nose of the hook safeguarding the load when side loading of the latch occurs.

High Performance Premium Grease

Load carrying ability, mechanical stability, corrosion protection, water resistance and increased operating temperature ranges are all improved by the using only the very best lubricant.

Overload protection

Designed for maximum safety, comfort, efficiency and ease of use, the operator friendly Hammerhead handle prevents the use of unauthorised extension bars overloading the SS11

Hooks

Drop forged and heat treated alloy hooks are furnished with heavy duty latch kits that fully engage into the nose of the hook offering maximum load security. The swivel hooks are attached to the yoke using high grade nuts & bolts allowing for complete inspection during any statutory inspection or written scheme maintenance. Recessed forgings offer full protection to the load chain anchor bolts on all our bottom hooks.

Chain end anchorage

Tiger have incorporated the ultimate safeguarding of a single point failure mode as described in IMCA DO28 Rev. 1 Note 7.2 by installing a new specially designed adjustable chain end stop profiled to fit the contours of the hoist body. This offers complete assurance to the operator, whilst maintaining the flexibility of “freewheeling” the chain to any required starting position.

Performance

The SS11 lever hoist has undergone a full test program that includes:

Type Testing

- Ultimate strength test, at least 4 times the Working load limit (WLL)

- Chain end anchorage test, passing at least 4 times the WLL without any restriction of the brake or gears

Test on every hoist

- Proof loading at 1.5 times the rated capacity

- Light load testing at maximum of 2% rated capacity

Salt Spray – Submersion Test Programme

The SS11 range of hoists has successfully been type tested to over 700 hours continuous exposure to an industry generated test programme that was specifically drawn up and agreed upon by a group of independent professionals incorporating ASTM B117 environmental conditions. This programme included over 50 individual load tests on the same hoist of varying weights at various timescales, to fully challenge the SS11.

Specifications

| Product Code | Capacity (tonne) | Effort (kg) | Effort (kg) with ext’n handle | Dimensions (mm) | Load Chain | Standard HOL (m) | Mass Kg @ std HOL | |||||||

| A | B | C | D | E | F | F1 | Diameter (mm) | No. of falls | ||||||

| SS-0080 | 0.8 | 23 | - | 128 | 240 | 275 | 158 | 99 | 30 | 28 | Ø6.3 | 1 | 3.0 | 9.1 |

| SS-0150 | 1.5 | 26 | - | 154 | 360 | 320 | 172 | 104 | 38 | 34 | Ø7.1 | 1 | 3.0 | 12.6 |

| SS-0300 | 3.0 | 38 | 22 | 182 | 360 | 400 | 195 | 108 | 43 | 35 | Ø10.0 | 1 | 3.0 | 22.0 |

| SS-0600 | 6.0 | 40 | 23.5 | 242 | 360 | 570 | 195 | 108 | 57 | 50 | Ø10.0 | 2 | 3.0 | 36.5 |

| SS-1000 | 10.0 | 47 | 27.5 | 370 | 360 | 630 | 195 | 108 | 71 | 54 | Ø10.0 | 3 | 3.0 | 56.3 |

| SS-2000 | 20.0 | 43 | - | 470 | 370 | 1050 | 251 | 161 | 90 | 70 | Ø10.0 | 6 | 3 | 174.0 |

Dimensional Images

|

|

|

|

| 800kg to 3000kg | 6000kg | 10000kg | 20000kg |

Tiger Adaptor Hoists are available with a drop-forged clevis adaptor allowing for the interchangeable range of EN1677 Tiger grade 100 clevis fittings.

This Tiger manufactured knuckle configuration gives 360° Rotation and 180° Pivot for maximum flexibility, whilst maintaining our 4:1 factor of safety at all angles.

- Available for Tiger TCB14 / SS12 chain blocks and PROLH / SS11 / TLH lever hoists.

- All fittings meet the standards of EN1677 grade 100 at 400°C tempering.

- Drop forged adaptor for maximum strength certified 4:1 FOS at all angles.

- Self-locking (safety) hook, clevis shackle, reevable egg (master) link or sling hook fitting available.

- Overload protection available.

- For lifting at angles (cross hauling/fleeting/drifting) with no deration.

- Chain Blocks – 500kg – 10t capacity.

- Lever Hoists – 800kg – 10t capacity.

Adaptor Sling Hook

Safety Hooks

Reevable Egg Link

Hoist Clevis Shackle

Adaptor Roation

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.