-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Lifting Slings and Components

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Runway Beam Monorail Crane Trolleys, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms and Jib Cranes

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

- Man-riding Hoists & Rescue Winches

-

Fall Arrest & Man-riding Systems

- Fall Arrest Davit Arms & Posts for Working at Height

- Sala Advanced Davit Arm Systems and Components

- Xtirpa Confined Space Davit Arm Systems and Components

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding & Rescue Tripods & Quadpods

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

- Home/

- Fall Arrest & Height Safety Equipment/

- Fall Arrest Systems & Man-riding Equipment/

- Manriding Systems, Baskets and Chairs/

- Suspended Access Manriding Baskets and Suspension Seats/

- Tractel Suspended Access, Man-riding Baskets and Mobile Suspension Seats/

- Tractel "Solsit" Electric Operation Temporary Use Suspended Working Seat With Integrated Fall Protection and Endless HOL

Tractel "Solsit" Electric Operation Temporary Use Suspended Working Seat With Integrated Fall Protection and Endless HOL

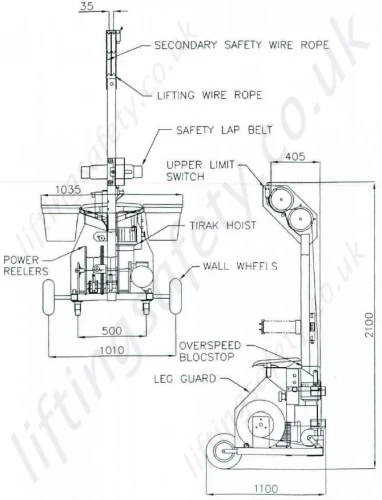

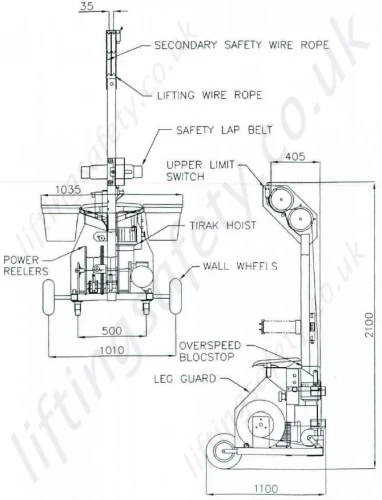

Single seat temporary suspended seat with integrated Tirak hoist and Blocstop safety device.

Tractel SOLSIT / T-3583

The SOLSIT, motorised seat for inspection and maintenance, has been specifically designed for man-riding applications. The compact design of the SOLSIT makes it extremely quick and simple to rig.

The SOLSIT is suitable for many light jobs and is fitted with a TIRAK X-300P series hoist and a TIRAK wire rope which passes through the machine. The working height is limited only by the length of the wire rope supplied.

In accordance with current safety regulations, a secondary safety wire rope is fitted in conjunction with a BLOCSTOP BSO, automatic secondary device.In the standard version the SOLSIT is supplied with 2 cleaning buckets, and 2 wall rollers to prevent damage to the facade and twisting of the unit.

- The equipment enables operators to carry out work which requires complete safety. Consequently, it is important to ensure that this equipment is only handed over for use to an operator who is competent and correctly trained to operate it in a safe and responsible manner.

- Particularly check the suspension anchor points of the SOLSIT. Ensure that the anchor points can accept at least 1.3 times the capacity of the hoist.

- Check that the lifting and safety wire ropes as well as the electric supply cable are sufficient for the job. The length of the wire ropes is marked on the ferrule of the hook or eye.

- Ensure that the diameter of the wire ropes is correct for the TIRAK hoist and BLOCSTOP safety device. Check the labels on the machines.

- When first put into operation and after every service-repair on the electrics, check the correct rotation of the TIRAK motor in relation to the controls. If necessary, call for an electrician to reverse the phase (3-phase motor).

The SOLSIT one-man seat is extremely compact and can pass through a man-hole of 45x54 cm. It can then be used inside very narrow furnaces, wells and chimneys. 2 containers are fitted for carrying tools and cleaning materials.

Built-in safety devices

- secondary safety wire rope

- overload safety device

- controlled lowering by centrifugal brake

- upper limit switch

- safety belt (SOLSIT one-man seat).

Fast installation and set up

The cradle or work seat can be very quickly installed and set up for operation. The two wire ropes are hooked onto the suspension point and the electric supply cable plugged in – depending on the model of TIRAK hoist – to a 220 V single phase or 220/380 V 3 phase supply. An extra power point for a drill or inspection lamp avoids the need for additional power supply cable.

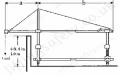

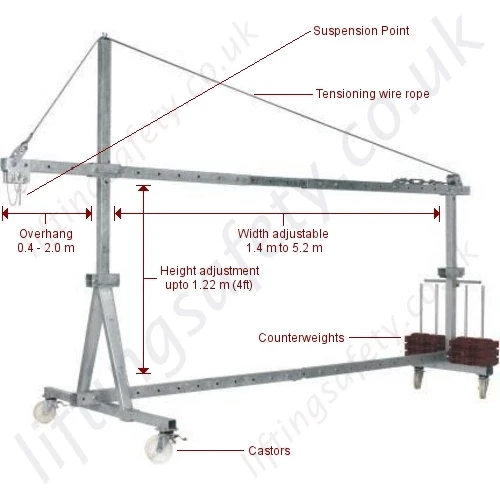

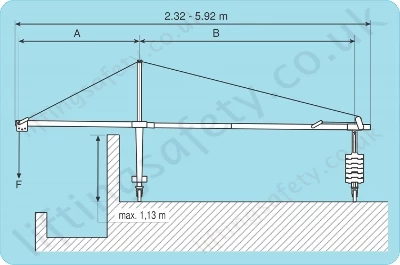

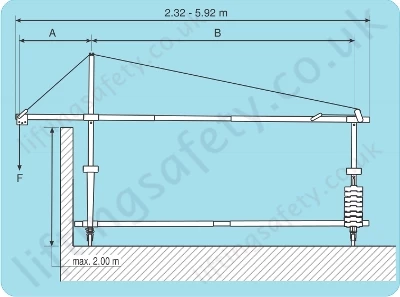

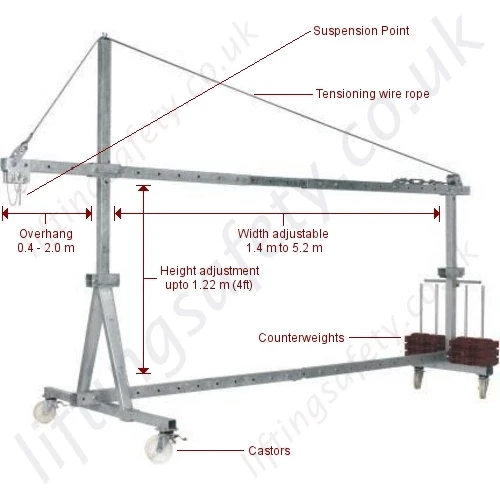

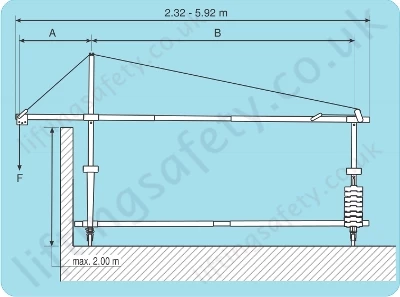

Mobile suspension jibs that allow very fast access to building facades. SWL of 150kg, 300kg, 400kg, 500kg, 800kg and 1000kg.

The mobile portable suspension jibs allow very fast access to the building facades using many types of temporary platforms.

Portable suspension jibs are robust and easy to assemble and to dismantle. They represent the ideal solution for nearly every flat roof, especially when the parapet is not strong enough to hold a load. The stability of the jibs is provided by counterweights. no roof penetration is required, reach (cantilever distance), height and SWL to our customers requirements.

Please contact our sales team for advise and / or a quotation.

|

|

|

|

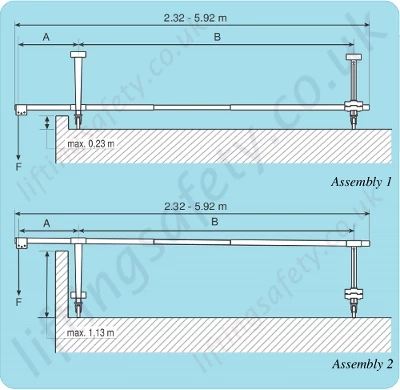

Standard Configurations

|

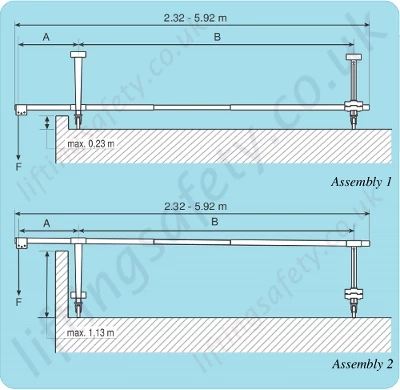

System 1

Two assemblies are possible:

|

|

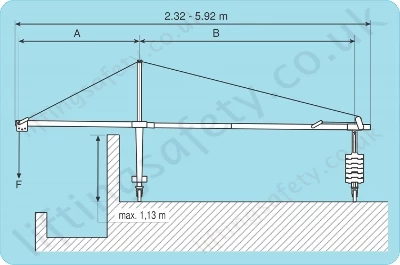

System 2

Model with reinforcing bracket and guy wire rope, recommended for longer overhangs (A) or heavy loads. |

|

System 3

Model with:

|

Dimensions

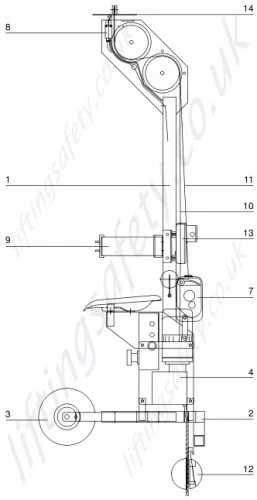

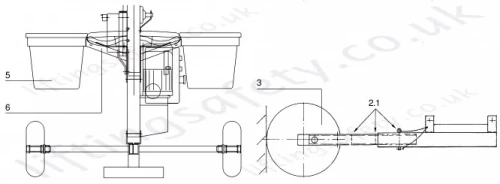

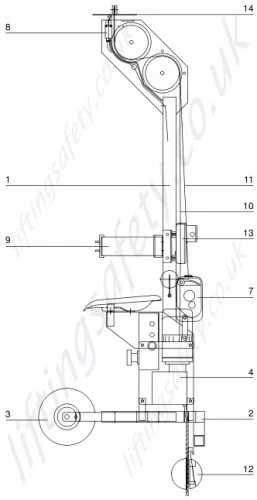

Assembly of The SOLSIT

- Stirrup

- Base frame

- Roller assembly

- TIRAK hoist, X-300P

- Bucket

- Frame support for bucket

- BLOCSTOP BSO 500 secondary safety device

- Upper limit switch

- Safety belt

- Lifting wire rope

- Safety wire rope

- Counterweight for safety wire rope

- Mechanical overload safety device

Assembly

Generally, the SOLSIT is delivered already assembled. However, if this is not possible, e.g. for transport reasons, follow the assembly instruction below.

- Fit the TIRAK hoist (4) with the motor turned upwards, to the stirrup (1) and base frame (2) and the overload safety device (13) connecting to the control box of the TIRAK hoist.

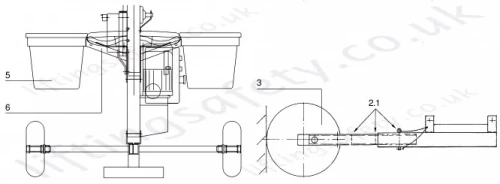

- Stabilise the equipment by fitting the roller assembly (3) into the base frame (2). Lock it into position using the clip pin (2.1). The base frame (3) has three holes, to allow adjustment of the distance between the SOLSIT and the facade.

- Fix the frame supports (6) for the buckets. Fit the 2 buckets (5).

- Fit the BLOCSTOP BSO (7) to the stirrup (1).

- Fix the upper limit switch (8) to the top of the mast (1). Connect to the control box of the TIRAK hoist (Fig. 3).

Pricing

The SOLSIT, motorised seat for inspection and maintenance, has been specifically designed for man-riding applications. The compact design of the SOLSIT makes it extremely quick and simple to rig.

The SOLSIT is suitable for many light jobs and is fitted with a TIRAK X-300P series hoist and a TIRAK wire rope which passes through the machine. The working height is limited only by the length of the wire rope supplied.

In accordance with current safety regulations, a secondary safety wire rope is fitted in conjunction with a BLOCSTOP BSO, automatic secondary device.In the standard version the SOLSIT is supplied with 2 cleaning buckets, and 2 wall rollers to prevent damage to the facade and twisting of the unit.

- The equipment enables operators to carry out work which requires complete safety. Consequently, it is important to ensure that this equipment is only handed over for use to an operator who is competent and correctly trained to operate it in a safe and responsible manner.

- Particularly check the suspension anchor points of the SOLSIT. Ensure that the anchor points can accept at least 1.3 times the capacity of the hoist.

- Check that the lifting and safety wire ropes as well as the electric supply cable are sufficient for the job. The length of the wire ropes is marked on the ferrule of the hook or eye.

- Ensure that the diameter of the wire ropes is correct for the TIRAK hoist and BLOCSTOP safety device. Check the labels on the machines.

- When first put into operation and after every service-repair on the electrics, check the correct rotation of the TIRAK motor in relation to the controls. If necessary, call for an electrician to reverse the phase (3-phase motor).

The SOLSIT one-man seat is extremely compact and can pass through a man-hole of 45x54 cm. It can then be used inside very narrow furnaces, wells and chimneys. 2 containers are fitted for carrying tools and cleaning materials.

Built-in safety devices

- secondary safety wire rope

- overload safety device

- controlled lowering by centrifugal brake

- upper limit switch

- safety belt (SOLSIT one-man seat).

Fast installation and set up

The cradle or work seat can be very quickly installed and set up for operation. The two wire ropes are hooked onto the suspension point and the electric supply cable plugged in – depending on the model of TIRAK hoist – to a 220 V single phase or 220/380 V 3 phase supply. An extra power point for a drill or inspection lamp avoids the need for additional power supply cable.

Mobile suspension jibs that allow very fast access to building facades. SWL of 150kg, 300kg, 400kg, 500kg, 800kg and 1000kg.

The mobile portable suspension jibs allow very fast access to the building facades using many types of temporary platforms.

Portable suspension jibs are robust and easy to assemble and to dismantle. They represent the ideal solution for nearly every flat roof, especially when the parapet is not strong enough to hold a load. The stability of the jibs is provided by counterweights. no roof penetration is required, reach (cantilever distance), height and SWL to our customers requirements.

Please contact our sales team for advise and / or a quotation.

|

|

|

|

Standard Configurations

|

System 1

Two assemblies are possible:

|

|

System 2

Model with reinforcing bracket and guy wire rope, recommended for longer overhangs (A) or heavy loads. |

|

System 3

Model with:

|

Dimensions

Assembly of The SOLSIT

- Stirrup

- Base frame

- Roller assembly

- TIRAK hoist, X-300P

- Bucket

- Frame support for bucket

- BLOCSTOP BSO 500 secondary safety device

- Upper limit switch

- Safety belt

- Lifting wire rope

- Safety wire rope

- Counterweight for safety wire rope

- Mechanical overload safety device

Assembly

Generally, the SOLSIT is delivered already assembled. However, if this is not possible, e.g. for transport reasons, follow the assembly instruction below.

- Fit the TIRAK hoist (4) with the motor turned upwards, to the stirrup (1) and base frame (2) and the overload safety device (13) connecting to the control box of the TIRAK hoist.

- Stabilise the equipment by fitting the roller assembly (3) into the base frame (2). Lock it into position using the clip pin (2.1). The base frame (3) has three holes, to allow adjustment of the distance between the SOLSIT and the facade.

- Fix the frame supports (6) for the buckets. Fit the 2 buckets (5).

- Fit the BLOCSTOP BSO (7) to the stirrup (1).

- Fix the upper limit switch (8) to the top of the mast (1). Connect to the control box of the TIRAK hoist (Fig. 3).

Products of Possible Interest

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.