-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Lifting Slings and Components

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Runway Beam Monorail Crane Trolleys, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms and Jib Cranes

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

- Man-riding Hoists & Rescue Winches

-

Fall Arrest & Man-riding Systems

- Fall Arrest Davit Arms & Posts for Working at Height

- Sala Advanced Davit Arm Systems and Components

- Xtirpa Confined Space Davit Arm Systems and Components

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding & Rescue Tripods & Quadpods

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

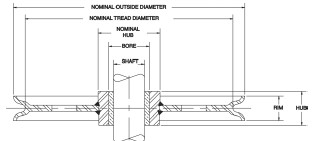

McKissick Sheaves- General Information

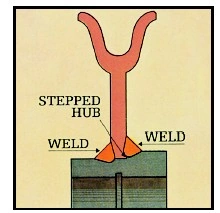

Stepped hub design proves better.

The McKissick hub is stepped to eliminate stress failure in the weld, common in traditional hub designs. The hub is pressed into place with complete metal-to-metal contact. This helps ensure an accurate alignment to the hubs axis so theres no wobble or lopping of the rotating sheave.

The precision aligned hub/sheave wheel combination adds to the bearing life and keeps the sheave on the job longer.

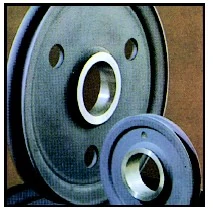

Closed die upset and roll forged not split.

Upsetting and roll forging forms the groove and flange walls in multiple steps, eliminating the need to split and weaken the groove. This exclusive forging process adds extra strength to the critical groove section. You can count on a McKissick sheave to give maximum life performance, because its forged to distribute the wire rope forces evenly over an accurately formed load surface. Plus, uniformity of the roll forged groove adds longer wire rope life.

Full range of standard sheave sizes.

Solid steel no casting.

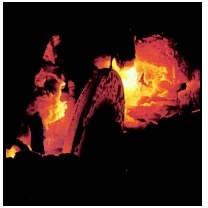

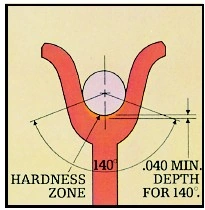

Flame hardened groove.

Crosbys hardening technique is a science. It provides a precise maximum hardness for wear-

resistance across the wire rope contact area. The McKissick sheave groove is flame hardened to a minimum 35 Rockwell C for a 140, contact area with the wire rope. The solid steel plate provides the ideal surface for flame hardening and a closer tolerance fit to the wire rope to reduce fatigue and wear.

Bearing selection to match your job requirement.

The McKissick Roll Forged sheave is available in the following configurations:

- Plain bore

- Bronze bushed

- Roller bearing

- Tapered roller bearing

- Lubrication thru hub

- Key ways

- Set screws

Ordering Information

McKissick sheaves come in a variety of sizes to suit your specific applications. Check the tables for the size, bearing style and price that best fits your application. For applications that require unique specifications Crosby can make minor modifications to many of the sheaves listed at a reasonable charge. We can also custom design and manufacture sheaves to your exact requirements. Contact Crosby Sales to order McKissick sheaves and include the stock number and quantity. For special requirements or custom designed sheaves, furnish the following important information:

|

|

Roll Forged Sheave Features

- Unique upset roll forging process provides a thicker groove section for extra strength.

- Stepped Hubs are precisely centered and mechanically locked in place.

- Wireline grooves on sheave diameters of 14" and larger are flamed hardened for extra wear resistance.

- All sheaves have solid steel webs with holes for easy handling.

- Sheave weights can be made heavier or lighter than shown to fit your specific application.

- For more information ask for our special brochure describing the complete roll forging process.

Sheave Bearing Application Information

Bronze Bushing -

Slow line speed, moderate load and moderate use,

Maximum Bearing Pressure (BP): 4500 PSI

Maximum Velocity at Bearing (BV): 1200 FPM

Maximum Pressure Velocity Factor (PV): 55000

| Formula for BP = |

Line Pull x Angle Factor (See Page 335) |

|

|

|

| Shaft Size x Hub Width (See example). |

Plain Bore-

Very slow line speed, very infrequent use, low load.

Faster line speeds, more frequent use, greater load.