-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Soft Lifting Slings

- Lifting Chain Slings

- Wire Rope Slings & Assemblies

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Beam Trolleys and Crane Bridges, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

-

Confined Space and Rescue Systems

- Xtirpa Confined Space Davit Arm Systems and Components

- Sala Advanced Davit Arm Systems and Components

- Genesi Confined Space Systems

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding Hoists & Rescue Winches

- Fall Arrest & Rescue Tripods

- Fall Arrest Davit Arms & Posts for Working at Height

-

Fall Arrest & Man-riding Systems

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

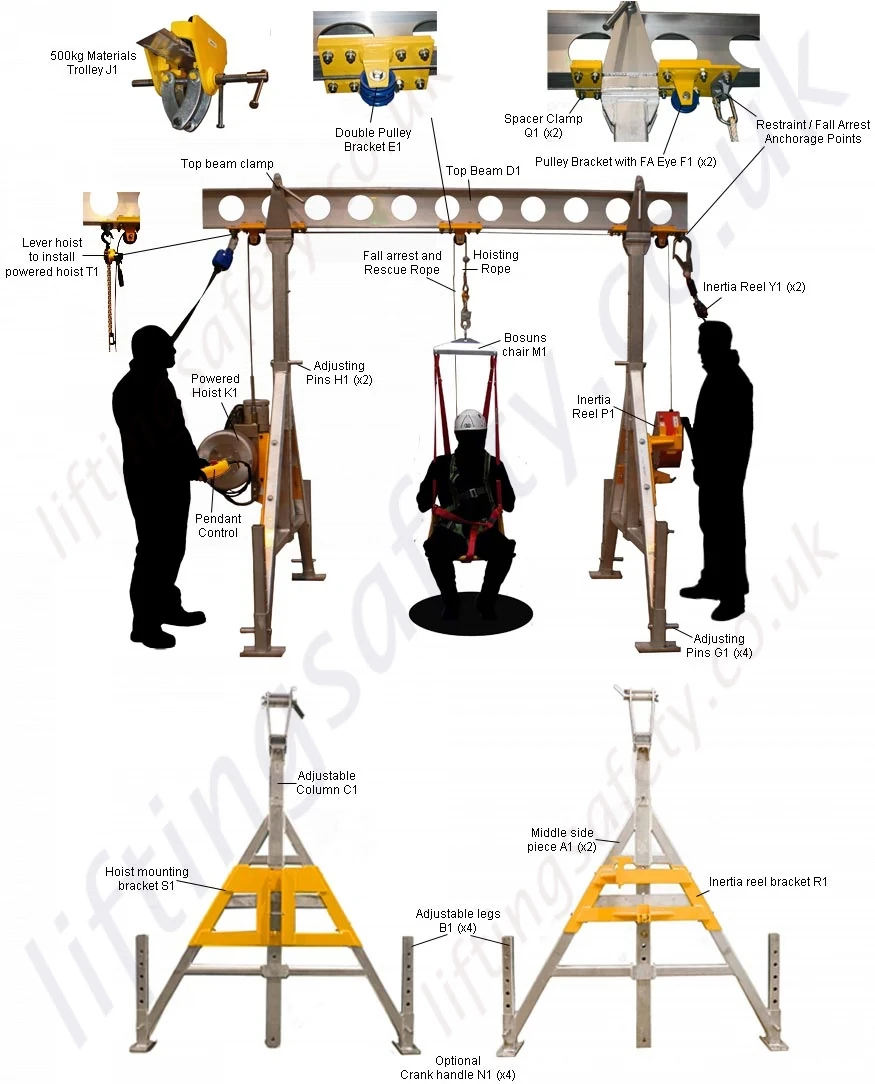

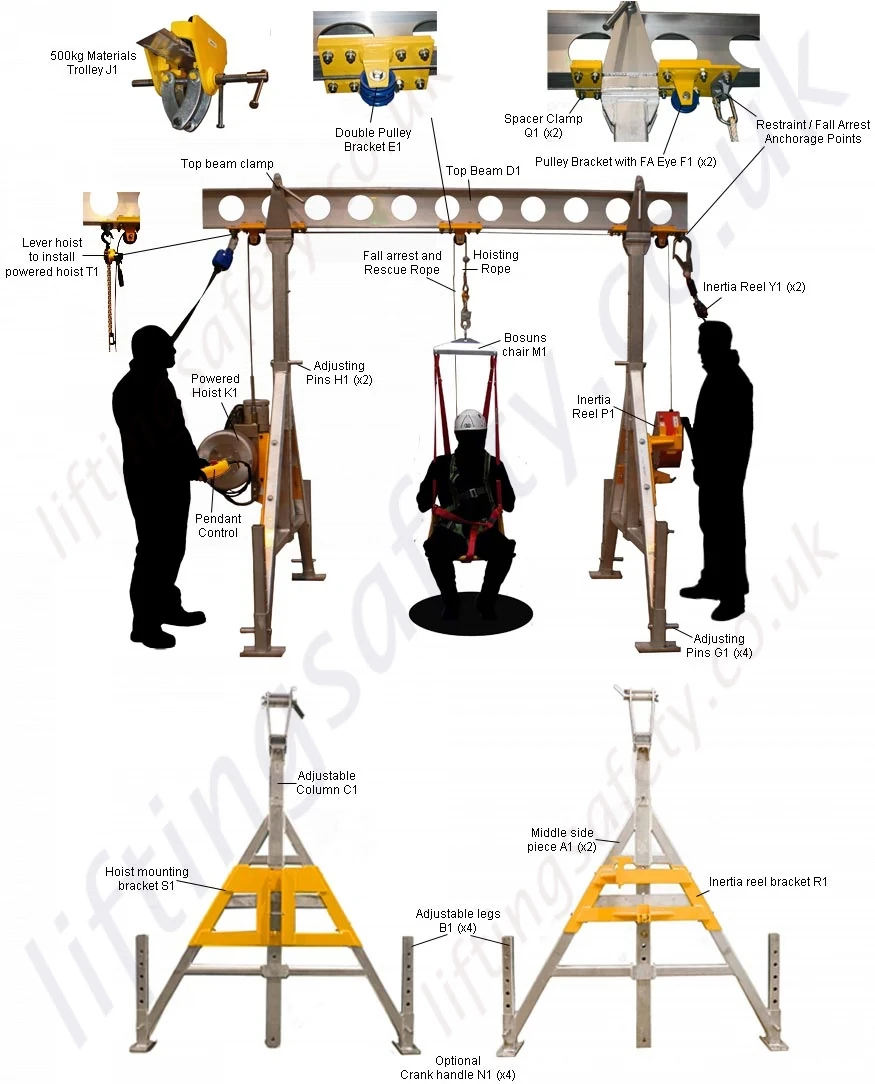

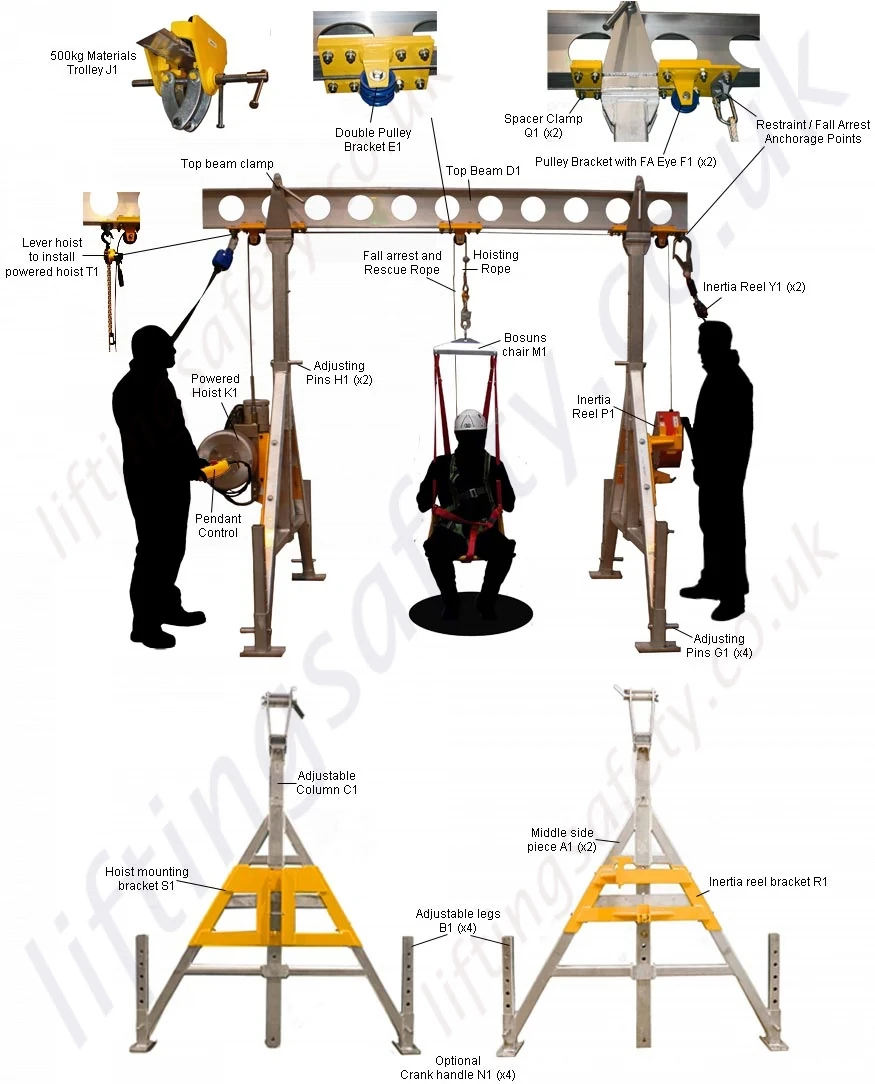

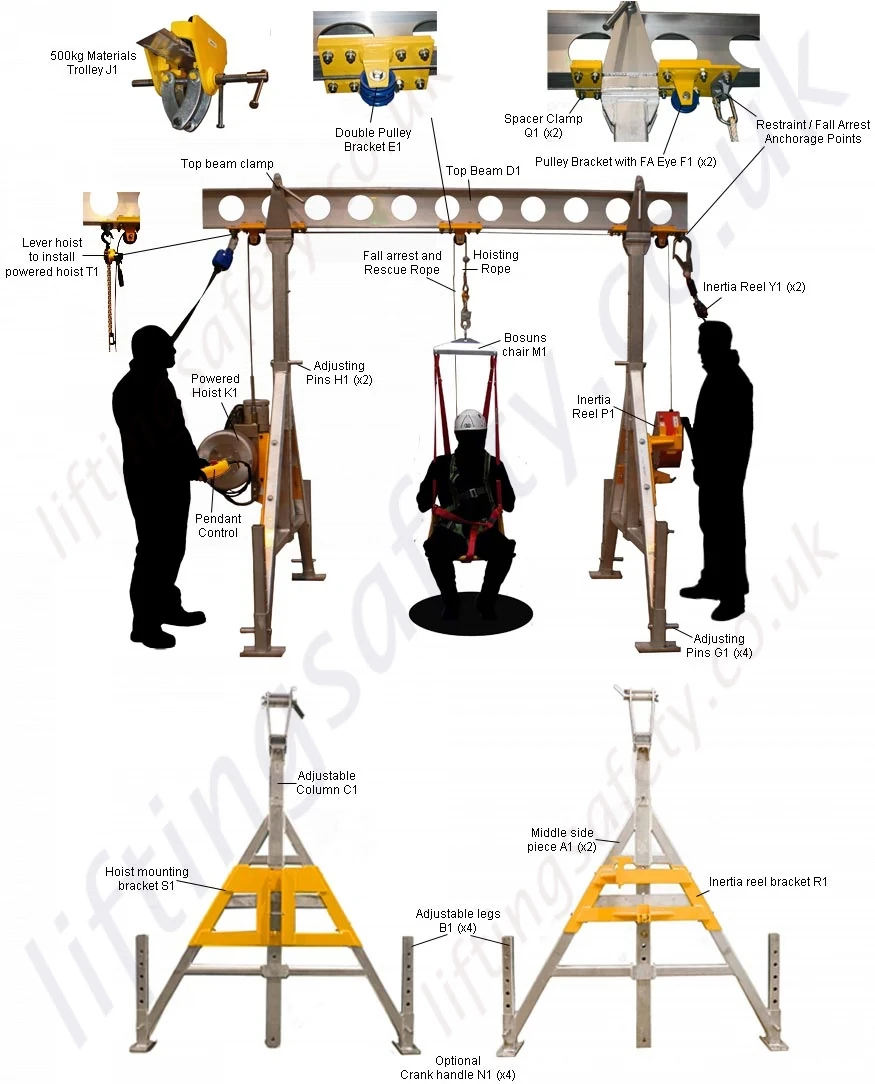

LiftingSafety Man-riding, Fall Arrest, Rescue and Materials Gantry System - Lightweight Aluminium, portable and adjustable (500kg For Materials)

Electric, Pneumatic or manual hoist with indefinite lifting height . 2m span and adjustable height (or bespoke) for man-riding, fall arrest / rescue.

MRG-3179

Unfortunately this system is no longer currently available. Please see our current range of mobile fall arrest systems for a possibly suitable alternative.

SELS offer our mobile lightweight aluminium fall arrest man riding gantry system with independent fall arrest and manual rescue winch. It is designed for maximum portability so that it can be adjusted in size to suit our customers working environment; both height, width and optional equipment and accessories.

The legs are also adjustable meaning that the gantry can be easily adjusted in all corners so that it can be made level in rough terrain; we also offer with a screw jack system that allows very fine adjustment of the gantry legs. For safety reasons we do not fit Castor's as used on lifting systems; the gantry is so light enough to move with out the need for castors.

Fully certified with EC Declaration of Conformity and comprehensive Operation and User Manual / spare parts lists. Every system is assembled before dispatch and load tested - including individual component parts!

Modular / KnockDown

The modular design of the gantry means that it is quickly assembled with only hand tools required. The modular or knock-down design means that the rescue gantry can be easily disassembled for transportation.

Super-seeding the requirements of EN795, we supply our Man Gantry only as a bespoke system; complete with specialist fall arrest / man-riding and rescue equipment for suspended working at height and restraint / fall arrest systems for the operator and rescuer. The important and unique feature is that we supply all systems designed to meet our customers specific height safety requirements.

Gantry Design Features

The general design of the Aluminium man-riding gantry system offers more space for manoeuvrability of the worker, operator and rescuer than you would get with a tripod system. The gantry can be fitted with anchorage points to suit your individual needs though as standard is fitted with 2 x overhead fall arrest / restraint anchorage points / eyes for use by the hoist operator and potentially a rescuers. The electric or pneumatic man-riding hoist is mounted one of the vertical 'A' side sections and the fall arrest / rescue winch to the other; the wire ropes then pass through a pulley / bracket system ending-up in the desired position that the worker will descend. Fitting the hoists to the gantry legs means that we avoid the necessity to work at height as would otherwise be needed if the unit was to be mounted to the overhead lifting beam. Virtually no manual handing is needed to install the hoists as we utilise lifting points installed on the overhead beam and the hoist along with a lever hoist to lift the hoist onto its mounting bracket.

Additional Information - Options!

All gantries are customized to our customers requirements with adjustable height and width. Standard maximum width is 2 metre and height adjustable from 1995mm to 3220mm (under beam) - special dimensions are available on request! All systems are supplied with specialist height safety equipment to provide safe operations while working at height.Working height with a spring reeling drum is possible at heights of up to 60 metre, we use a separate (not attached) cable reeler when greater working heights are needed. Manual fall arrest inertia reels with integrated retrievers are supplied to a maximum working height of 40 metres; greater heights / depths use an alternative fall arrest / rescue system (not shown here).

The arrangement illustrated shows a a 110v electric powered man-riding hoist for suspended man access, also fitted is a fall arrest inertia reel; this provides fall arrest protection (a back-up) in the event of a failure to the electric hoist, the inbuilt hand operated winch provides a means of rescue in the event of a failure to the primary hoist (Mechanical, electrical or power failure).

Contact our sales team for a quotation and for advise on equipment to suit your your needs.

The Electric / Pneumatic Hoist is fitted with an upper limit switch and end of rope sensor. The hoist is also fitted with an overload alarm that can be set to stall to prevent injury should the equipment or person get caught / snagged while being hoisted. The load at which the hoist will stall must be factory set and can be chosen by the customer.

Inappropriate Application

The man-riding gantry system is to be used for lifting of persons, with a maximum total weight of 136kg with 2m span inside the legs of gantry and for lifting materials to a maximum capacity of 500kg while also providing fall arrest protection. Materials cannot be lifted by the powered man-riding hoist or rescue hoist and materials cannot be lifted when the system is being used for man-riding purposes. Man-riding and materials handling must be independent operations.

Labelled Gantry Diagram

Main Gantry Features

|

All the pulley sheave have quick release pins for fast reeving of the lead cable from the inertia reel / lifting hoist to the person man-riding. |

|

The overhead extremity brackets house both a pulley and fall arrest / restraint anchorage points and should be bolted to the underside of the lifting beam when the gantry is in the lowest position. The load cable from the fall arrest/ rescue inertia reels and from the hoist rise vertically then are deflected over a pulley sheave through 90 degrees, horizontally along the underside of the lifting beam . |

|

The 'Spacer Clamps' make the gantry system rigid when assembled - helps stop undesired movement when assembled. |

|

Stability and extremity brackets; this image is from the right side. Right and left brackets are identical. |

|

The karabiners from both the inertia reel and lifting hoist pass through a cavity specially designed into the vertical upright 'A' frames. |

|

Load cables from the inertia reel and hoist deflect through 90 degrees ober the pulley Twin Pulley Sheave Bracket This bracket should be bolted to the underside of the top beam directly above the access chamber (Man hole etc). The Pulley sheaves are also fixed in place with quick release pins! The bracket should be bolted to the underside of the lifting top beam when the gantry is in the lowest position. |

|

The user should check the Identification Labels to ensure gantry certification is in-date. |

Electric / Pneumatic / Hydraulic Hoist Installation

|

We recommend this bracket is permanently fastened to one of the 'A' frame to which the hoist is to be mounted. |

|

Lifting of the hoist onto the bracket is done without the need for manual handing by use of a small 'lever hoist'. Connect one lever hoist hook to the overhead eye on the top beam and to the other hook to the eye pre-installed onto the hoist then raise into position! |

|

The hoist raised to the correct height. |

|

Connect the bracket pre-installed on the bottom of the hoist to the Yellow bracket as shown in this image with the nut finger tight. |

|

Gently push the hoist forward using the bottom bolt as a pivot until the second two fixing holes line-up - put these bolts in place! |

|

This image shows the hoist correctly installed - all three fixings in place and tightened. The lever Hoist is now removed. |

|

View from the underside |

|

Electric man riding hoist from the left side; showing the motor and control box with overload alarm. |

|

Installed view from the right showing the the cable reeler in the foreground |

|

Front view including the hand held pendant control. |

|

Rear view. |

Inertia Reel Installation

|

We recommend this bracket is permanently fastened to one of the 'A' frame to which the inertia reel retriever block is to be mounted. |

|

The fall arrest inertia retriever block is not to heavy to be lifted with care by 1 or 2 persons. The installer manually lifts into place. The arrow on this image points to a location of the anchorage pin. This easily pushes into place and instantly takes the all the weight of the inertia reel. |

|

Gently maneuver the inertia reel using the bottom pin as a pivot until the second two fixing holes line-up - screw these bolts in place! |

|

This image shows the inertia reel correctly installed. |

|

Detailed front view of the inertial retriever block and the bracket |

|

Rear view with the inertia reel installed. |

Parts List

| Description | Part Number |

| 1 x Operation and Service Instructions | - |

| 1 x Gantry system consisting of: | - |

| 2 x Side pieces | MRG3179B-A1 |

| 4 x legs for side pieces | MRG3179B-B1 |

| 2 x supports for top beam | MRG3179B-C1 |

| 1 x Top beam (runway) | MRG3179B-D1 |

| 1 x Double pulley bracket |

MRG3179B-E1 |

| 2 x Pulley bracket with fall arrest eye |

MRG3179B-F1 |

| 4 x bolts for leg adjustment 160 mm long | MRG3179B-G1 |

| 2 x bolts for height adjustment 170 mm long | MRG3179B-H1 |

| 1 x 500kg materials trolley | MRG3179B-J1 |

| 1 x Electric powered man-riding hoist, 40 metre of cable, complete with pendant control, 110v, top and bottom limit switches, top hook suspended and c/w overload alarm | MRG3179B-K1 |

| 1 x Bosun’s chair / suspension seat (optional extra). | MRG3179B-M1 |

| 1 x Set of adjustable legs with crank handle (optional extra). | MRG3179B-N1 |

| 1 x 40 metre fall arrest inertia reel with integrated manual rescue winch | MRG3179B-P1 |

| 2 x Spacer clamp | MRG3179B-Q1 |

| 1 x Inertia reel bracket | MRG3179B-R1 |

| 1 x Hoist mounting bracket | MRG3179B-S1 |

| 1 x 250kg capacity manual lever hoist x 3 metre height of lift for lifting the powered man-riding hoist onto the man-riding trolley clamp. | MRG3179B-T1 |

| 2 x Fall arrest inertia reel. | MRG3179B-Y1 |

Safety first

- Please read completely these operating instructions before using the Gantry man-riding system.

- Ensure a rescue plan is in place and approved before persons commence working at height.

- The gantry system must only be used by competent and trained operatives. It is recommended that all operatives are trained by the manufacturer, Selby Engineering and Lifting Safety Ltd, contact our training department on 0044 1977 684600.

- Keep the operating instructions carefully in the proximity of the Gantry Crane, for future reference when in doubt!

- Unconventional changes or installing of additional devices will lead to the cancellation of any liability by the dealer or manufacturer.

- Remove all articles from the working area, which could potentially be a possible source of danger!

- Only authorized persons may use the Gantry Crane. Each user must have read and understood this documentation.

- Before each use, check the basic parts and welding seams for damages. In case of defects do not use the Crane. The use by an unauthorized third party must be prevented by suitable measures.

- Make certain that the location where the Crane is to be assembled offers suitable foundation carrying capacity.

- The supporting foundation must provide a carrying capacity of from 12.000 kg/m², provided no support plates are laid beneath the legs of the crane.

- The maximum permissible carrying capacity for man-riding is 136kg and 500kg for materials

- Lifting of materials and persons at the same is forbidden.

- Standing under a suspended load is absolutely forbidden!

- Carrying capacities may not be pulled on a slant.

- The bolt for the height adjustment must be inserted at the peak of the side piece (A-Form). It is FORBIDDEN to permit the bolt for the height adjustment on the cross bridge of the side piece (A-Form) to be used for supporting purposes.

- The Gantry may not be used with a wind speed of 10 m/s.

- All bolts must be safely secured to prevent unintentional loosening.

- Maintain a clean working area and provide for adequate lighting.

- When operating the gantry system suitable PPE / fall arrest and / or restraint and / or Protective work clothing / equipment must be used as required, in accordance with user risk assessment and method statement.

- During use, check to ensure that no one is in the proximity of the Crane, in order to avoid danger to a third party.

- Check and make certain that all parts are correctly installed.

- In case of damages or malfunctions occurring with the machine, de-commission immediately and contact Selby Engineering and Lifting Safety (0044 1977 684600) immediately.

- Protect the Gantry system from environmental factors, e.g. rain, sunrays, humidity, dust etc.

- In case of damage or other reasons which prevent the further use of the gantry totally remove from service, to prevent accidental use by others.

- If disposing of the machine or parts then be all items must be disposed of in accordance with recycling and environmental regulations.

Maintenance and Inspection

To comply with LOLER 98 The gantry crane / man-riding system must be thoroughly examined by SELS (the manufacturer) or a trained and competent person at intervals no longer that every 6 months. This is the maximum permissible period between inspections and therefore must be reduced dependant on working practice – for example how often the equipment is used, by whom it is used, environmental conditions etc...

These Items must also be returned to the manufacturers for annual service and certification: The powered man-riding hoist, the fall arrest inertia reel / rescue winch and the manual hand chain hoist

Unfortunately, this product has been discontinued and/or is no longer available. Please contact us for details on possible alternative products.

Contact Us About This ProductUnfortunately this system is no longer currently available. Please see our current range of mobile fall arrest systems for a possibly suitable alternative.

SELS offer our mobile lightweight aluminium fall arrest man riding gantry system with independent fall arrest and manual rescue winch. It is designed for maximum portability so that it can be adjusted in size to suit our customers working environment; both height, width and optional equipment and accessories.

The legs are also adjustable meaning that the gantry can be easily adjusted in all corners so that it can be made level in rough terrain; we also offer with a screw jack system that allows very fine adjustment of the gantry legs. For safety reasons we do not fit Castor's as used on lifting systems; the gantry is so light enough to move with out the need for castors.

Fully certified with EC Declaration of Conformity and comprehensive Operation and User Manual / spare parts lists. Every system is assembled before dispatch and load tested - including individual component parts!

Modular / KnockDown

The modular design of the gantry means that it is quickly assembled with only hand tools required. The modular or knock-down design means that the rescue gantry can be easily disassembled for transportation.

Super-seeding the requirements of EN795, we supply our Man Gantry only as a bespoke system; complete with specialist fall arrest / man-riding and rescue equipment for suspended working at height and restraint / fall arrest systems for the operator and rescuer. The important and unique feature is that we supply all systems designed to meet our customers specific height safety requirements.

Gantry Design Features

The general design of the Aluminium man-riding gantry system offers more space for manoeuvrability of the worker, operator and rescuer than you would get with a tripod system. The gantry can be fitted with anchorage points to suit your individual needs though as standard is fitted with 2 x overhead fall arrest / restraint anchorage points / eyes for use by the hoist operator and potentially a rescuers. The electric or pneumatic man-riding hoist is mounted one of the vertical 'A' side sections and the fall arrest / rescue winch to the other; the wire ropes then pass through a pulley / bracket system ending-up in the desired position that the worker will descend. Fitting the hoists to the gantry legs means that we avoid the necessity to work at height as would otherwise be needed if the unit was to be mounted to the overhead lifting beam. Virtually no manual handing is needed to install the hoists as we utilise lifting points installed on the overhead beam and the hoist along with a lever hoist to lift the hoist onto its mounting bracket.

Additional Information - Options!

All gantries are customized to our customers requirements with adjustable height and width. Standard maximum width is 2 metre and height adjustable from 1995mm to 3220mm (under beam) - special dimensions are available on request! All systems are supplied with specialist height safety equipment to provide safe operations while working at height.Working height with a spring reeling drum is possible at heights of up to 60 metre, we use a separate (not attached) cable reeler when greater working heights are needed. Manual fall arrest inertia reels with integrated retrievers are supplied to a maximum working height of 40 metres; greater heights / depths use an alternative fall arrest / rescue system (not shown here).

The arrangement illustrated shows a a 110v electric powered man-riding hoist for suspended man access, also fitted is a fall arrest inertia reel; this provides fall arrest protection (a back-up) in the event of a failure to the electric hoist, the inbuilt hand operated winch provides a means of rescue in the event of a failure to the primary hoist (Mechanical, electrical or power failure).

Contact our sales team for a quotation and for advise on equipment to suit your your needs.

The Electric / Pneumatic Hoist is fitted with an upper limit switch and end of rope sensor. The hoist is also fitted with an overload alarm that can be set to stall to prevent injury should the equipment or person get caught / snagged while being hoisted. The load at which the hoist will stall must be factory set and can be chosen by the customer.

Inappropriate Application

The man-riding gantry system is to be used for lifting of persons, with a maximum total weight of 136kg with 2m span inside the legs of gantry and for lifting materials to a maximum capacity of 500kg while also providing fall arrest protection. Materials cannot be lifted by the powered man-riding hoist or rescue hoist and materials cannot be lifted when the system is being used for man-riding purposes. Man-riding and materials handling must be independent operations.

Labelled Gantry Diagram

Main Gantry Features

|

All the pulley sheave have quick release pins for fast reeving of the lead cable from the inertia reel / lifting hoist to the person man-riding. |

|

The overhead extremity brackets house both a pulley and fall arrest / restraint anchorage points and should be bolted to the underside of the lifting beam when the gantry is in the lowest position. The load cable from the fall arrest/ rescue inertia reels and from the hoist rise vertically then are deflected over a pulley sheave through 90 degrees, horizontally along the underside of the lifting beam . |

|

The 'Spacer Clamps' make the gantry system rigid when assembled - helps stop undesired movement when assembled. |

|

Stability and extremity brackets; this image is from the right side. Right and left brackets are identical. |

|

The karabiners from both the inertia reel and lifting hoist pass through a cavity specially designed into the vertical upright 'A' frames. |

|

Load cables from the inertia reel and hoist deflect through 90 degrees ober the pulley Twin Pulley Sheave Bracket This bracket should be bolted to the underside of the top beam directly above the access chamber (Man hole etc). The Pulley sheaves are also fixed in place with quick release pins! The bracket should be bolted to the underside of the lifting top beam when the gantry is in the lowest position. |

|

The user should check the Identification Labels to ensure gantry certification is in-date. |

Electric / Pneumatic / Hydraulic Hoist Installation

|

We recommend this bracket is permanently fastened to one of the 'A' frame to which the hoist is to be mounted. |

|

Lifting of the hoist onto the bracket is done without the need for manual handing by use of a small 'lever hoist'. Connect one lever hoist hook to the overhead eye on the top beam and to the other hook to the eye pre-installed onto the hoist then raise into position! |

|

The hoist raised to the correct height. |

|

Connect the bracket pre-installed on the bottom of the hoist to the Yellow bracket as shown in this image with the nut finger tight. |

|

Gently push the hoist forward using the bottom bolt as a pivot until the second two fixing holes line-up - put these bolts in place! |

|

This image shows the hoist correctly installed - all three fixings in place and tightened. The lever Hoist is now removed. |

|

View from the underside |

|

Electric man riding hoist from the left side; showing the motor and control box with overload alarm. |

|

Installed view from the right showing the the cable reeler in the foreground |

|

Front view including the hand held pendant control. |

|

Rear view. |

Inertia Reel Installation

|

We recommend this bracket is permanently fastened to one of the 'A' frame to which the inertia reel retriever block is to be mounted. |

|

The fall arrest inertia retriever block is not to heavy to be lifted with care by 1 or 2 persons. The installer manually lifts into place. The arrow on this image points to a location of the anchorage pin. This easily pushes into place and instantly takes the all the weight of the inertia reel. |

|

Gently maneuver the inertia reel using the bottom pin as a pivot until the second two fixing holes line-up - screw these bolts in place! |

|

This image shows the inertia reel correctly installed. |

|

Detailed front view of the inertial retriever block and the bracket |

|

Rear view with the inertia reel installed. |

Parts List

| Description | Part Number |

| 1 x Operation and Service Instructions | - |

| 1 x Gantry system consisting of: | - |

| 2 x Side pieces | MRG3179B-A1 |

| 4 x legs for side pieces | MRG3179B-B1 |

| 2 x supports for top beam | MRG3179B-C1 |

| 1 x Top beam (runway) | MRG3179B-D1 |

| 1 x Double pulley bracket |

MRG3179B-E1 |

| 2 x Pulley bracket with fall arrest eye |

MRG3179B-F1 |

| 4 x bolts for leg adjustment 160 mm long | MRG3179B-G1 |

| 2 x bolts for height adjustment 170 mm long | MRG3179B-H1 |

| 1 x 500kg materials trolley | MRG3179B-J1 |

| 1 x Electric powered man-riding hoist, 40 metre of cable, complete with pendant control, 110v, top and bottom limit switches, top hook suspended and c/w overload alarm | MRG3179B-K1 |

| 1 x Bosun’s chair / suspension seat (optional extra). | MRG3179B-M1 |

| 1 x Set of adjustable legs with crank handle (optional extra). | MRG3179B-N1 |

| 1 x 40 metre fall arrest inertia reel with integrated manual rescue winch | MRG3179B-P1 |

| 2 x Spacer clamp | MRG3179B-Q1 |

| 1 x Inertia reel bracket | MRG3179B-R1 |

| 1 x Hoist mounting bracket | MRG3179B-S1 |

| 1 x 250kg capacity manual lever hoist x 3 metre height of lift for lifting the powered man-riding hoist onto the man-riding trolley clamp. | MRG3179B-T1 |

| 2 x Fall arrest inertia reel. | MRG3179B-Y1 |

Safety first

- Please read completely these operating instructions before using the Gantry man-riding system.

- Ensure a rescue plan is in place and approved before persons commence working at height.

- The gantry system must only be used by competent and trained operatives. It is recommended that all operatives are trained by the manufacturer, Selby Engineering and Lifting Safety Ltd, contact our training department on 0044 1977 684600.

- Keep the operating instructions carefully in the proximity of the Gantry Crane, for future reference when in doubt!

- Unconventional changes or installing of additional devices will lead to the cancellation of any liability by the dealer or manufacturer.

- Remove all articles from the working area, which could potentially be a possible source of danger!

- Only authorized persons may use the Gantry Crane. Each user must have read and understood this documentation.

- Before each use, check the basic parts and welding seams for damages. In case of defects do not use the Crane. The use by an unauthorized third party must be prevented by suitable measures.

- Make certain that the location where the Crane is to be assembled offers suitable foundation carrying capacity.

- The supporting foundation must provide a carrying capacity of from 12.000 kg/m², provided no support plates are laid beneath the legs of the crane.

- The maximum permissible carrying capacity for man-riding is 136kg and 500kg for materials

- Lifting of materials and persons at the same is forbidden.

- Standing under a suspended load is absolutely forbidden!

- Carrying capacities may not be pulled on a slant.

- The bolt for the height adjustment must be inserted at the peak of the side piece (A-Form). It is FORBIDDEN to permit the bolt for the height adjustment on the cross bridge of the side piece (A-Form) to be used for supporting purposes.

- The Gantry may not be used with a wind speed of 10 m/s.

- All bolts must be safely secured to prevent unintentional loosening.

- Maintain a clean working area and provide for adequate lighting.

- When operating the gantry system suitable PPE / fall arrest and / or restraint and / or Protective work clothing / equipment must be used as required, in accordance with user risk assessment and method statement.

- During use, check to ensure that no one is in the proximity of the Crane, in order to avoid danger to a third party.

- Check and make certain that all parts are correctly installed.

- In case of damages or malfunctions occurring with the machine, de-commission immediately and contact Selby Engineering and Lifting Safety (0044 1977 684600) immediately.

- Protect the Gantry system from environmental factors, e.g. rain, sunrays, humidity, dust etc.

- In case of damage or other reasons which prevent the further use of the gantry totally remove from service, to prevent accidental use by others.

- If disposing of the machine or parts then be all items must be disposed of in accordance with recycling and environmental regulations.

Maintenance and Inspection

To comply with LOLER 98 The gantry crane / man-riding system must be thoroughly examined by SELS (the manufacturer) or a trained and competent person at intervals no longer that every 6 months. This is the maximum permissible period between inspections and therefore must be reduced dependant on working practice – for example how often the equipment is used, by whom it is used, environmental conditions etc...

These Items must also be returned to the manufacturers for annual service and certification: The powered man-riding hoist, the fall arrest inertia reel / rescue winch and the manual hand chain hoist

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.