-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Soft Lifting Slings

- Lifting Chain Slings

- Wire Rope Slings & Assemblies

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Runway Beam Monorail Crane Trolleys, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

-

Confined Space and Rescue Systems

- Xtirpa Confined Space Davit Arm Systems and Components

- Sala Advanced Davit Arm Systems and Components

- Genesi Confined Space Systems

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding Hoists & Rescue Winches

- Fall Arrest & Rescue Tripods

- Fall Arrest Davit Arms & Posts for Working at Height

-

Fall Arrest & Man-riding Systems

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

Tractel Dynafor LLXH Range from 15,000kg to 250,000kg

Tractel Dynafor LLXH / TD-3343

This Page has now expired. Please Contact us with your requirements for a superseding model or suitable alternative.

The DYNAFOR™ LLXH series are the industrial standard for load indicators.

Extreme accuracy with full traceability: 0.2% of the maximum measuring range.

In addition to the stand-alone application, the LLXH is suitable for very complex projects. Combined with monitoring software, it can be used for simultaneously reading, managing and storing measuring data from up to 8 load cells.

The remote display is designed for simultaneously reading 4 load cells.

Delivery includes the Dynafor™ LLXH, remote display, charging adapter, user manual, calibration report and declaration of conformity.

The series up to 50 t are supplied in a plastic case and the series up to 100 t and 250 t in a wooden transport box.

Important: If you are using a single unit, then you will require a display. If you are to use is a set (e.g. in use as a set of 4), then atleast one of the units must have a display.

Operating Principle

Strain gauge measurement of the extension, within its limits of elasticity, of a metal body subjected to traction stress. The sensor generates an electrical signal that is proportional to the load. This signal is processed by a micro-processor analyser and then transmitted via radio waves to the display unit, which immediately displays the load applied to the sensor to which it is linked. The display unit is compatible with all of the LLX 2

model sensors, irrespective of their capacity.

Technical Specifications

- 25 mm LCD display LCD with backlight.

- Safety factor: at least 4 times WLL.

- Units: kg, t/daN, kN/lbs, ton (US).

- ZigBee 2.4 GHz, default range 80 m.

- In conformity with: CE2006/42/EC, CEM2004/108/CE, EN300/440-2 V1.1.1.

- Protection class: IP66.

- Remote display: IP54.

- Operating temperature: -20 to +40 °C.

- .Test load: 2 times WLL.

Functional

- Taring.

- Overload indication at 10% overload.

- Max. measured value peak mode.

- Managing safety thresholds.

- Storing measurements.

- Dynamic effect filter settings.

- Automatic shutdown.

- Battery life (3 AA): 1,000 hours.

- Automatic zeroing.

Optional Accessories

- PC connection Kit.

- Connecting shackles.

- Swivel hooks as LLX.

- I.P. 67 Protection.

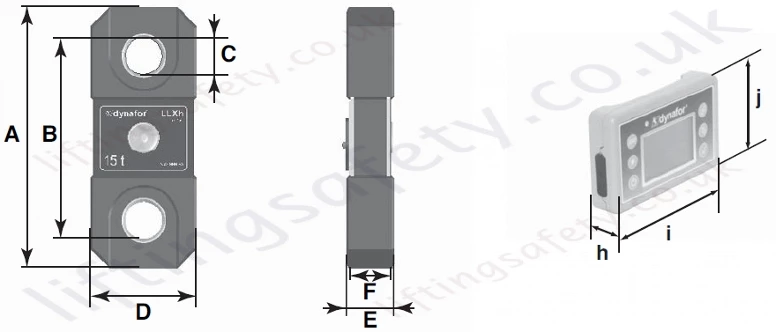

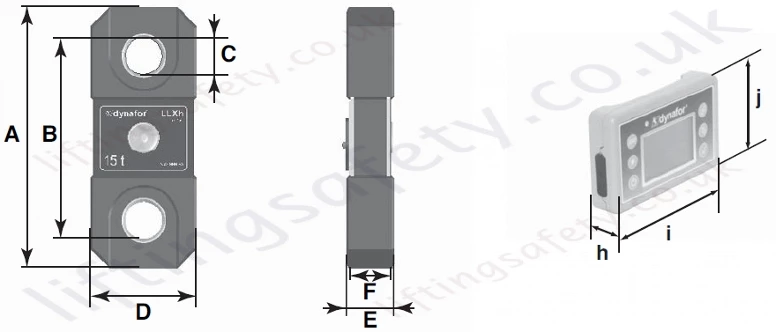

Dimensions

| Part No: | LLXH 15 t |

LLXH 25 t |

LLXH 50 t |

LLXH 100 t |

LLXH 250 t |

Display | |

| Maximum capacity | kg | 15000 | 25000 | 50000 | 100000 | 250000 | All |

| Test load | kg | 30000 | 50000 | 100000 | 200000 | 500000 | - |

| Safety coefficient | Minimum 4 | - | |||||

| Precision | 0.2 % according to ISO 376 . 21°C | - | |||||

| daN | 30 | 50 | 100 | 200 | 500 | - | |

| Increment | daN | 5 | 10 | 20 | 50 | 100 | <- |

| Max. display | 16500 daN | 27500 daN | 55000 daN | 110.00 t | 275.00 t | <- | |

| Number height | mm | - | - | - | - | - | 25 |

| Autonomy | From 300 to 1000 h depending of functions | 48 h | |||||

| Radio scope | m | 80 (in open field) (I.P. 67 = 60) | |||||

| RF Technology | 2.4 Ghz | ||||||

| Weight | kg | 4 | 6.6 | 15.1 | 46 | 215 | 0.180 |

| IP Protection | I.P. 65 (option : I.P. 67) | I.P. 54 | |||||

| Usage | From - 20° to 40°C | ||||||

| Sensitivity to T° | 0.05% per 10°C | - | |||||

| Sensor material | Aluminium | - | |||||

| Dimensions mm | A | 320 | 360 | 440 | 660 | 905 | - |

| B | 247.5 | 277 | 338 | 488 | 685 | - | |

| ØC | 47.5 | 56 | 72 | 108 | 150 | - | |

| D | 130 | 134 | 164 | 260 | 424 | - | |

| E | 58 | 68 | 98 | 118 | 248 | - | |

| F | 48 | 58 | 86 | 104 | 190 | - | |

| h | - | - | - | - | - | 26.7 | |

| i | - | - | - | - | - | 131 | |

| j | - | - | - | - | - | 82 | |

Unfortunately, this product has been discontinued and/or is no longer available. Please contact us for details on possible alternative products.

Contact Us About This ProductThis Page has now expired. Please Contact us with your requirements for a superseding model or suitable alternative.

The DYNAFOR™ LLXH series are the industrial standard for load indicators.

Extreme accuracy with full traceability: 0.2% of the maximum measuring range.

In addition to the stand-alone application, the LLXH is suitable for very complex projects. Combined with monitoring software, it can be used for simultaneously reading, managing and storing measuring data from up to 8 load cells.

The remote display is designed for simultaneously reading 4 load cells.

Delivery includes the Dynafor™ LLXH, remote display, charging adapter, user manual, calibration report and declaration of conformity.

The series up to 50 t are supplied in a plastic case and the series up to 100 t and 250 t in a wooden transport box.

Important: If you are using a single unit, then you will require a display. If you are to use is a set (e.g. in use as a set of 4), then atleast one of the units must have a display.

Operating Principle

Strain gauge measurement of the extension, within its limits of elasticity, of a metal body subjected to traction stress. The sensor generates an electrical signal that is proportional to the load. This signal is processed by a micro-processor analyser and then transmitted via radio waves to the display unit, which immediately displays the load applied to the sensor to which it is linked. The display unit is compatible with all of the LLX 2

model sensors, irrespective of their capacity.

Technical Specifications

- 25 mm LCD display LCD with backlight.

- Safety factor: at least 4 times WLL.

- Units: kg, t/daN, kN/lbs, ton (US).

- ZigBee 2.4 GHz, default range 80 m.

- In conformity with: CE2006/42/EC, CEM2004/108/CE, EN300/440-2 V1.1.1.

- Protection class: IP66.

- Remote display: IP54.

- Operating temperature: -20 to +40 °C.

- .Test load: 2 times WLL.

Functional

- Taring.

- Overload indication at 10% overload.

- Max. measured value peak mode.

- Managing safety thresholds.

- Storing measurements.

- Dynamic effect filter settings.

- Automatic shutdown.

- Battery life (3 AA): 1,000 hours.

- Automatic zeroing.

Optional Accessories

- PC connection Kit.

- Connecting shackles.

- Swivel hooks as LLX.

- I.P. 67 Protection.

Dimensions

| Part No: | LLXH 15 t |

LLXH 25 t |

LLXH 50 t |

LLXH 100 t |

LLXH 250 t |

Display | |

| Maximum capacity | kg | 15000 | 25000 | 50000 | 100000 | 250000 | All |

| Test load | kg | 30000 | 50000 | 100000 | 200000 | 500000 | - |

| Safety coefficient | Minimum 4 | - | |||||

| Precision | 0.2 % according to ISO 376 . 21°C | - | |||||

| daN | 30 | 50 | 100 | 200 | 500 | - | |

| Increment | daN | 5 | 10 | 20 | 50 | 100 | <- |

| Max. display | 16500 daN | 27500 daN | 55000 daN | 110.00 t | 275.00 t | <- | |

| Number height | mm | - | - | - | - | - | 25 |

| Autonomy | From 300 to 1000 h depending of functions | 48 h | |||||

| Radio scope | m | 80 (in open field) (I.P. 67 = 60) | |||||

| RF Technology | 2.4 Ghz | ||||||

| Weight | kg | 4 | 6.6 | 15.1 | 46 | 215 | 0.180 |

| IP Protection | I.P. 65 (option : I.P. 67) | I.P. 54 | |||||

| Usage | From - 20° to 40°C | ||||||

| Sensitivity to T° | 0.05% per 10°C | - | |||||

| Sensor material | Aluminium | - | |||||

| Dimensions mm | A | 320 | 360 | 440 | 660 | 905 | - |

| B | 247.5 | 277 | 338 | 488 | 685 | - | |

| ØC | 47.5 | 56 | 72 | 108 | 150 | - | |

| D | 130 | 134 | 164 | 260 | 424 | - | |

| E | 58 | 68 | 98 | 118 | 248 | - | |

| F | 48 | 58 | 86 | 104 | 190 | - | |

| h | - | - | - | - | - | 26.7 | |

| i | - | - | - | - | - | 131 | |

| j | - | - | - | - | - | 82 | |

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.