-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Soft Lifting Slings

- Lifting Chain Slings

- Wire Rope Slings & Assemblies

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Beam Trolleys and Crane Bridges, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

-

Confined Space and Rescue Systems

- Xtirpa Confined Space Davit Arm Systems and Components

- Sala Advanced Davit Arm Systems and Components

- Genesi Confined Space Systems

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding Hoists & Rescue Winches

- Fall Arrest & Rescue Tripods

- Fall Arrest Davit Arms & Posts for Working at Height

-

Fall Arrest & Man-riding Systems

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

- Home/

- Lifting Equipment/

- Screwjacks, Linear Actuators, Rotary Unions and ACME Ball Screws and Nuts/

- Duff Norton Rotary Union's/

- "2000 Series" Rotary Union

"2000 Series" Rotary Union

Heavy duty rotary union with spaced ballbearings to withstand radial and thrust loads.

2000 Series / SRU-4090

- Description

- Dimensional Specifications

- Performance Charts

- Components and Mounting

- Rotary Union Design

- Pricing (Buy/Quote)

2000 Series Rotary Union

Features and Benefits

- Heavy Duty design - designed with two ball bearings spaced to withstand radial and thrust loads.

- Easy Maintenance - designed with an intergral flange that allows repairs without removing the housing from the machine.

- No leakage in tough applications - Compression springs in the 2000 series provide even loading across the seal surfaces to maintain zero leakage even in low pressure applications.

- Easy mounting - The flange attaches directly to the machine journal, providing inherently concentric mounting, minimizing overhang, and partially relieving bearing load to increase service life.

2000 Series Rotary Union Mono Flow Dimensional Diagram

| Nominal Pipe Size | Part Number | Repair Cartidge | B (3) | F | T | Mounting Flange Diameter | Bolt Circle Diameter | Flange Type | Counterbore | Bolt Hole Size | Number of Bolt Holes (4) | H | P | Diameter (x) | Diameter (o) | C | |

| Diameter | Depth | ||||||||||||||||

| 2 | 730747C | 441781C | 2 | 12-3/4 | 1-7/16 | 10 | 7-1/8 | 2 | 9.002 to 9.004 | 3/16 | 11/16 | 4 | 5-1/2 | N/A | 5-1/4 | - | - |

| 3 | 730841C | 441845C | 3 | 16-1/8 | 1-3/4 | 9-1/2 | 7-9/16 | 2 | 8 | 7-1/4 | N/A | 6-5/16 | - | - | |||

| 4 | 730842C | 441846C | 4 | 20-1/4 | 1-3/4 | 11-1/2 | 8-15/16 | 2 | 10.824 to 10.820 | 13/16 | 6 | 9-1/8 | 6-3/4 | 7-3/4 | 1/8 | 5-3/4 | |

2000 Series Rotary Union Dual Flow with Revolving Siphon Diagram

| Nom. Pipe Size | Part No. | Repair Cartridge |

B (3) |

F | T | Mounting Flange Dia. | Bolt Circle Dia. | Flange Type |

Counterbore |

Bolt Hole Size | No. of Bolt Holes | H | P |

Dia. (x) |

Dia. (o) |

K (1) |

M (2) |

N |

J (3) |

S | E | R | |

| Dia. | Depth | ||||||||||||||||||||||

| 2 | 730843C | 441847C | 1-1/2 | 10 | 1-7/16 | 10 | 7-1/8 | 2 | 9.002 to 9.004 | 3/16 | 11/16 | 4 | 4-5/8 | - | - | - | 3/4 | .991 to .997 | 4-1/4 | 1-1/2 | 13-3/8 | 6-5/8 | N/A |

| 3 | 730737C | 441786C | 2-1/2 | 12-1/2 | 1-3/4 | 9-1/2 | 7-9/16 | 8 | 7-1/8 | 5-1/2 | 6-1/4 | 1-3/8 | 1-1/2 | 1.865 to 1.871 | 2-1/2 | 16-1/4 | 8-3/8 | 18-1/4 | |||||

| 4 | 730852C | 441860C | 2-1/2 | 15-3/8 | 1-3/4 | 11-1/2 | 8-15/16 | 10.820 to 10.824 | 13/16 | 6 | 6-1/8 | 7-3/4 | 2-1/2 | 2.801 to 2.807 | 2-1/2 | 19-3/8 | 8-7/8 | 21 | |||||

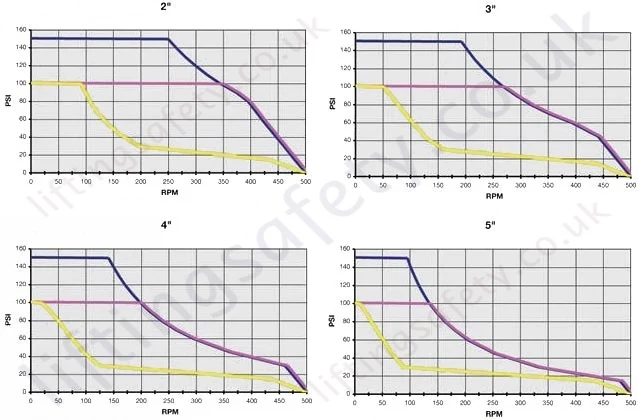

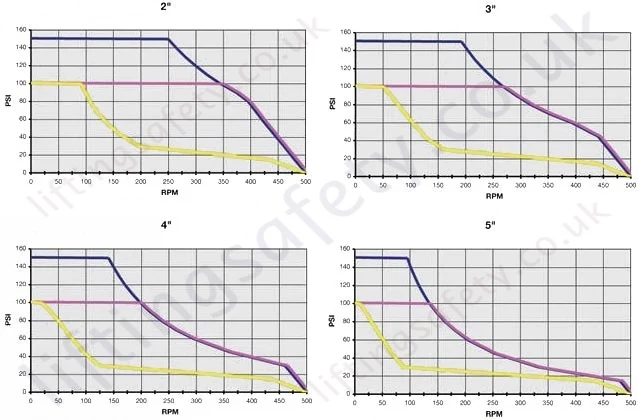

Performance Charts

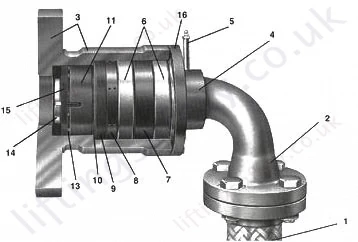

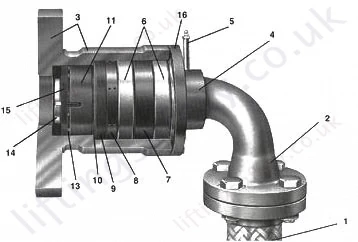

Components and Mounting

- Flexible Hose eliminates complex piping, allows adjustment of rolls without re-piping. Allows rotary joint to "float" so as to avoid unnecessary strain on sealing surfaces. A flexible hose either rubber or metal - must always be used with rotary joints.

- Flanged Inlet elbow of steel is a 150 lb. ASA flange type.

- Flanged Rotating Housing prevents leakage under pressure and protects the internal parts for a long service life. The flanged housing attaches directly to the machine journal, providing inherently concentric mounting, minimizes overhang. The housing may rotate in either direction without causing back out problems.

- Stationary Shaft is constructed of steel. It serves as a conduit for the fluid transfer from the flanged inlet into the revolving flanged housing.

- Lubrication Fitting located on the stationary shaft allows lubrication of the ball bearings while the rotary joint is in operation.

- Two Single Row, Widely Spaced Ball Bearings for radial and thrust loads.

- Grease Ring Assembly of steel, ground and spaced for ball bearing load sharing for increased life.

- Drain Ring is made of steel. It allows minute start-up leakage from entering the ball bearings.

- Seal Ring forms the primary rotating seal with the face ring. The seal ring is constructed of carbon graphite to provide a low friction, wear resistant surface.

- Gasket provides an effective seal between the housing and the fluid chamber.

- The Face Ring constructed of hardened and tempered stainless steel mates with the seal ring to form the primary seal.

- O-Ring Elastomer (not shown) of ethylene propylene for hot water applications. For higher temperature applications, a perfluoroelastomer is used.

- Compression Springs apply an initial pressure between the face ring and seal ring to provide sealing for low pressure applications.

- Drive Collar keys the face ring and the shaft together to prevent rotation.

- Retainer Rings secure the internal components to the shaft.

- Flanged Secures the internal components within the flanged housing. This allows quick rotary repair and less machine downtime.

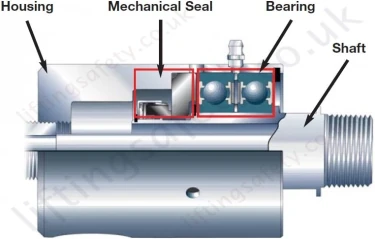

Rotary Union Design

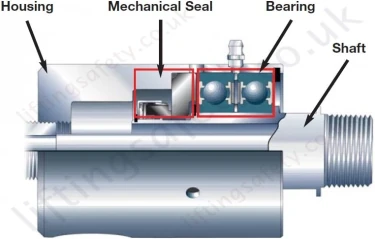

While rotating joints come in many shapes, sizes, and configurations, they always have the same four basic components: housing, a shaft, a bearing (or bearings) and a seal.

Mechanical Seal

The heart of the Rotary Union or rotary joint is the seal.

The seal prevents the medium (water, oil, air, etc) from leaking outside the Rotary Union while the Rotary Union is in operation.

Duff-Norton uses four basic types of mechanical seals in its Rotary Unions: 1) pusher-type end face mechanical seal, 2) non-pusher type end face mechanical seal, 3) lip seals and 4) o-ring seal. Rotary Unions may have more than one seal.

Bearing

The second most important part of the Rotary Union is the bearing. A Rotary Union may have only one bearing or multiple bearings.

Roller bearings, such as ball bearings and tapered roller bearings, or non-roller bearings, like graphite bearings and bronze bushings, may be used in the Rotary Union.

The bearings are always used to allow a part of the joint, either the shaft or the housing, to rotate.

Shaft

The shaft is the component that carries the medium through the Rotary Union into the drum or roll. In many cases, the shaft will turn with the drum or roll. In some cases, like in larger flanged rotary Unions, the shaft may be stationary while the housing rotates. The bearings and seal are typically assembled around the shaft.

Housing

The housing is the component that holds all of the other elements of the Rotary Union together. The housing has an inlet port, which is a threaded port to which the hose supplying the medium will be attached .

The Rotary Union may also have an outlet port, if the same joint is being used both to supply fluid to a roll and to remove fluid from the roll. In smaller Rotary Unions, the housing is stationary. In larger Rotary Unions, the housing maybe bolted to the drum or roll using a flange. In these cases, the housing rotates at the same speed as the drum.

2000 Series Rotary Union

Features and Benefits

- Heavy Duty design - designed with two ball bearings spaced to withstand radial and thrust loads.

- Easy Maintenance - designed with an intergral flange that allows repairs without removing the housing from the machine.

- No leakage in tough applications - Compression springs in the 2000 series provide even loading across the seal surfaces to maintain zero leakage even in low pressure applications.

- Easy mounting - The flange attaches directly to the machine journal, providing inherently concentric mounting, minimizing overhang, and partially relieving bearing load to increase service life.

2000 Series Rotary Union Mono Flow Dimensional Diagram

| Nominal Pipe Size | Part Number | Repair Cartidge | B (3) | F | T | Mounting Flange Diameter | Bolt Circle Diameter | Flange Type | Counterbore | Bolt Hole Size | Number of Bolt Holes (4) | H | P | Diameter (x) | Diameter (o) | C | |

| Diameter | Depth | ||||||||||||||||

| 2 | 730747C | 441781C | 2 | 12-3/4 | 1-7/16 | 10 | 7-1/8 | 2 | 9.002 to 9.004 | 3/16 | 11/16 | 4 | 5-1/2 | N/A | 5-1/4 | - | - |

| 3 | 730841C | 441845C | 3 | 16-1/8 | 1-3/4 | 9-1/2 | 7-9/16 | 2 | 8 | 7-1/4 | N/A | 6-5/16 | - | - | |||

| 4 | 730842C | 441846C | 4 | 20-1/4 | 1-3/4 | 11-1/2 | 8-15/16 | 2 | 10.824 to 10.820 | 13/16 | 6 | 9-1/8 | 6-3/4 | 7-3/4 | 1/8 | 5-3/4 | |

2000 Series Rotary Union Dual Flow with Revolving Siphon Diagram

| Nom. Pipe Size | Part No. | Repair Cartridge |

B (3) |

F | T | Mounting Flange Dia. | Bolt Circle Dia. | Flange Type |

Counterbore |

Bolt Hole Size | No. of Bolt Holes | H | P |

Dia. (x) |

Dia. (o) |

K (1) |

M (2) |

N |

J (3) |

S | E | R | |

| Dia. | Depth | ||||||||||||||||||||||

| 2 | 730843C | 441847C | 1-1/2 | 10 | 1-7/16 | 10 | 7-1/8 | 2 | 9.002 to 9.004 | 3/16 | 11/16 | 4 | 4-5/8 | - | - | - | 3/4 | .991 to .997 | 4-1/4 | 1-1/2 | 13-3/8 | 6-5/8 | N/A |

| 3 | 730737C | 441786C | 2-1/2 | 12-1/2 | 1-3/4 | 9-1/2 | 7-9/16 | 8 | 7-1/8 | 5-1/2 | 6-1/4 | 1-3/8 | 1-1/2 | 1.865 to 1.871 | 2-1/2 | 16-1/4 | 8-3/8 | 18-1/4 | |||||

| 4 | 730852C | 441860C | 2-1/2 | 15-3/8 | 1-3/4 | 11-1/2 | 8-15/16 | 10.820 to 10.824 | 13/16 | 6 | 6-1/8 | 7-3/4 | 2-1/2 | 2.801 to 2.807 | 2-1/2 | 19-3/8 | 8-7/8 | 21 | |||||

Performance Charts

Components and Mounting

- Flexible Hose eliminates complex piping, allows adjustment of rolls without re-piping. Allows rotary joint to "float" so as to avoid unnecessary strain on sealing surfaces. A flexible hose either rubber or metal - must always be used with rotary joints.

- Flanged Inlet elbow of steel is a 150 lb. ASA flange type.

- Flanged Rotating Housing prevents leakage under pressure and protects the internal parts for a long service life. The flanged housing attaches directly to the machine journal, providing inherently concentric mounting, minimizes overhang. The housing may rotate in either direction without causing back out problems.

- Stationary Shaft is constructed of steel. It serves as a conduit for the fluid transfer from the flanged inlet into the revolving flanged housing.

- Lubrication Fitting located on the stationary shaft allows lubrication of the ball bearings while the rotary joint is in operation.

- Two Single Row, Widely Spaced Ball Bearings for radial and thrust loads.

- Grease Ring Assembly of steel, ground and spaced for ball bearing load sharing for increased life.

- Drain Ring is made of steel. It allows minute start-up leakage from entering the ball bearings.

- Seal Ring forms the primary rotating seal with the face ring. The seal ring is constructed of carbon graphite to provide a low friction, wear resistant surface.

- Gasket provides an effective seal between the housing and the fluid chamber.

- The Face Ring constructed of hardened and tempered stainless steel mates with the seal ring to form the primary seal.

- O-Ring Elastomer (not shown) of ethylene propylene for hot water applications. For higher temperature applications, a perfluoroelastomer is used.

- Compression Springs apply an initial pressure between the face ring and seal ring to provide sealing for low pressure applications.

- Drive Collar keys the face ring and the shaft together to prevent rotation.

- Retainer Rings secure the internal components to the shaft.

- Flanged Secures the internal components within the flanged housing. This allows quick rotary repair and less machine downtime.

Rotary Union Design

While rotating joints come in many shapes, sizes, and configurations, they always have the same four basic components: housing, a shaft, a bearing (or bearings) and a seal.

Mechanical Seal

The heart of the Rotary Union or rotary joint is the seal.

The seal prevents the medium (water, oil, air, etc) from leaking outside the Rotary Union while the Rotary Union is in operation.

Duff-Norton uses four basic types of mechanical seals in its Rotary Unions: 1) pusher-type end face mechanical seal, 2) non-pusher type end face mechanical seal, 3) lip seals and 4) o-ring seal. Rotary Unions may have more than one seal.

Bearing

The second most important part of the Rotary Union is the bearing. A Rotary Union may have only one bearing or multiple bearings.

Roller bearings, such as ball bearings and tapered roller bearings, or non-roller bearings, like graphite bearings and bronze bushings, may be used in the Rotary Union.

The bearings are always used to allow a part of the joint, either the shaft or the housing, to rotate.

Shaft

The shaft is the component that carries the medium through the Rotary Union into the drum or roll. In many cases, the shaft will turn with the drum or roll. In some cases, like in larger flanged rotary Unions, the shaft may be stationary while the housing rotates. The bearings and seal are typically assembled around the shaft.

Housing

The housing is the component that holds all of the other elements of the Rotary Union together. The housing has an inlet port, which is a threaded port to which the hose supplying the medium will be attached .

The Rotary Union may also have an outlet port, if the same joint is being used both to supply fluid to a roll and to remove fluid from the roll. In smaller Rotary Unions, the housing is stationary. In larger Rotary Unions, the housing maybe bolted to the drum or roll using a flange. In these cases, the housing rotates at the same speed as the drum.

You May Also Like

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.