-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Soft Lifting Slings

- Lifting Chain Slings

- Wire Rope Slings & Assemblies

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Beam Trolleys and Crane Bridges, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

-

Confined Space and Rescue Systems

- Xtirpa Confined Space Davit Arm Systems and Components

- Sala Advanced Davit Arm Systems and Components

- Genesi Confined Space Systems

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding Hoists & Rescue Winches

- Fall Arrest & Rescue Tripods

- Fall Arrest Davit Arms & Posts for Working at Height

-

Fall Arrest & Man-riding Systems

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

- Home/

- Fall Arrest & Height Safety Equipment/

- Confined Space Rescue Systems and Equipment/

- Sala Advanced Davit Arm Systems and Components/

- Sala Advanced "Pole Hoist Davit". Lightweight Aluminium For Manriding using Independent Overhead Anchorage

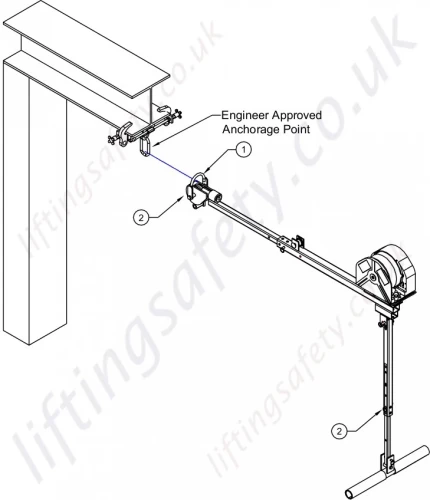

Sala Advanced "Pole Hoist Davit". Lightweight Aluminium For Manriding using Independent Overhead Anchorage

Connected via single anchor point, allowing you to work from direction from any angle. Complete with optional man-riding hoist.

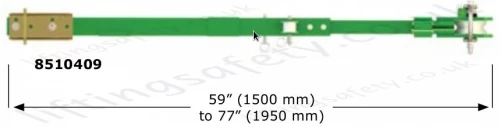

A-3508

The Advanced Pole Hoist attaches with a carabiner on the universal bracket to a suitable anchor point, allowing you to work in any direction from any angle. The Advanced Pole Hoist has a unique swivel head that rotates 360 degrees, providing unparalleled flexibility in both vertical and horizontal confined-space entries. Overall length adjusts from either 4’ - 7’ (1.2 m - 2.13 m) or 6’ - 10’ (1.8 m - 3.05 m) for positioning attendant for working in close quarters. Custom Pole Hoist sizes are available.

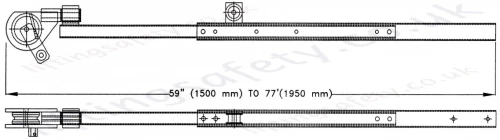

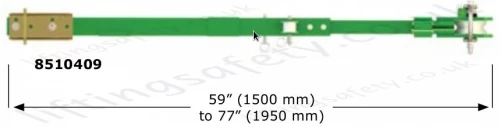

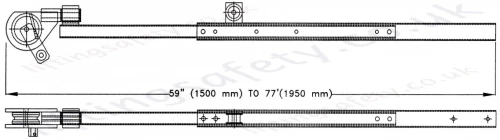

The Advanced Pole Hoist attaches with a carabiner on the universal bracket to a suitable anchor point, allowing you to work in any direction from any angle. The Advanced Pole Hoist has a unique swivel head that rotates 360 degrees, providing unparalleled flexibility in both vertical and horizontal confined-space entries. Overall length adjusts from either 4’ - 7’ (1.2 m - 2.13 m) or 6’ - 10’ (1.8 m - 3.05 m) for positioning attendant for working in close quarters. Custom Pole Hoist sizes are available.Advanced 4’ - 7’ (1.2m - 2.13m) Extendable Pole Hoist.

| Model | Description |

| 8510409 | 4’-7’ (1.2 m - 2.13 m) Extendable Pole Hoist, swivel head & hardware. Includes winch bracket. |

| 8516303 | 4’-7’ (1.2 m - 2.13 m) Extendable Pole Hoist, swivel head & stainless steel hardware. Includes winch bracket. |

| Weight: 12 lbs (5.4 kg) | |

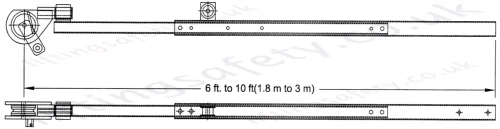

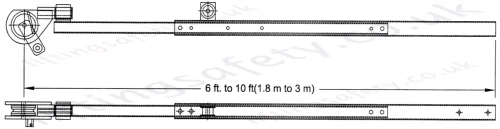

Advanced 6’ - 10’ (1.8 m - 3.05 m) Extendable Pole Hoist.

| Model | Description |

| 8510476 | 6’-10’ (1.8 m - 3.05 m) Extendable Pole Hoist, swivel head & hardware. Includes winch bracket. |

| 8520869 | 6’-10’ (1.8 m - 3.05 m) Extendable Pole Hoist, swivel Head & stainless steel hardware. Includes winch bracket. |

| Weight 14 lbs (6.4 kg) | |

The lightweight Pole Hoist is an extremely versatile piece of confined space entry / retrieval and rescue equipment. Simply attch via carabiner and the universal attachment ring to a suitable anchor point to work in ant direction from any angle. Overall length adjusts 1.8m to 3m (6' - 10' ft). For positioning personnel or working in confined space. Designed for use with Sala (UCL) safety systems winches.

Powder coated welded aluminum construction with zinc plated steel hardware.

Mounting Requirements

Anchor points for the pole hoist must be capable of withstanding a minimum load of 907 kg (2000 lbs) 4.4 KN.

General Specifications

| Specifications | kg | lbs |

| Rated Capacity (working load) | 204kg | 450lbs |

| Max. Allowed arresting force (M.A.F) rating for retractable devices ro shock absorbers | 453.6kg (4.4kn) | 1000lbs |

| Proof Load | 907kg | 2000lbs |

| Proof Test | UCT-133 | |

| Weight | ||

| Pole Hoist | 6.3kg | 14lbs |

| T-Bar Leg Assembly | 3kg | 7lbs |

Dimensions

| Material and Construction | |

| General Construction | Welded Aluminum / Steel |

| Weld Certification | CWB-47.2, CWB-47.1 |

| Base Material | 6061-T6, 5052 Aluminum |

| Sleeve | 6061-T6 Aluminum |

| Hardware | GR.5/GR.8 Steel, Zinc Plated |

| Finish | Gray Powder Coat |

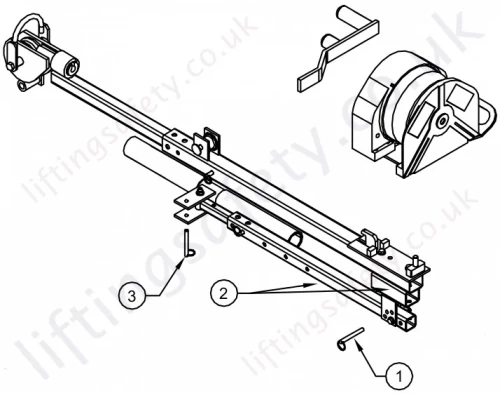

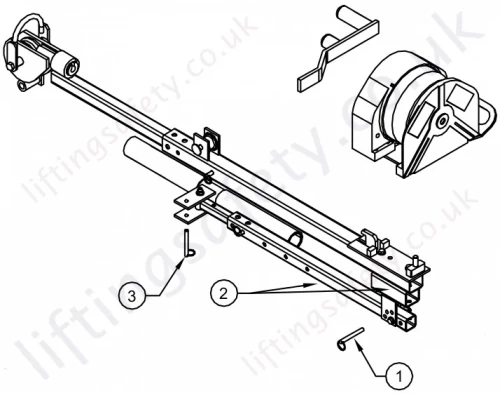

A) Setting up the Pole Hoist

- Remove all parts from strorage / transport bags

containers etc. and layout on ground. - Remove Pin (1) from T-bar leg assembly (2),

rotate leg and replace pin. Remove Pin(3)

from T-bar leg assembly rotate foot assembly and replace pin. - Remove Pin(4) to adjust T-bar leg assembly to a comfortable height

for winch operation.

B) Winch and Cable Routing Installation

- Install winch with upper slot in back plate (4) over hook

on flat quick mount plate (5). - Swing winch in and down so that the mounting stud (6)

engages the hole in the winch carrying handle (7). - Thread clamp knob (8) onto stud (6) and tighten securely

by hand. - Pay out 5' to 10' of cable from winch, maintaining at least

10 lb. (5 kg) of tension on cable at all times. - Remove cable roller pin (9) & guide pulley (10) from pole

hoist mast assembly (11). Place cable under guide pulley

and replace guide pulley & cable roller pin. - Rotate pole hoist head assembly (12) so that slots

through head align. Place cable through slot in head

assembly and over pulley and around cable retainer

spring (13).

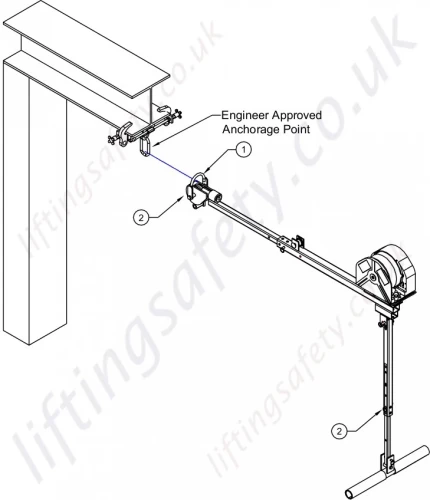

C) Pole Hoist Installation to Rated Anchor Point

- Using hanger bracket(1) on top pulley assembly (2), hang pole hoist using certified anchorage point and certified hardware.

- Make sure the T-bar leg(3) assembly is as vertical as possible to

support the weight of winch while in use.

D) Installation of Winches, Self-Retracting Lifelines (SLR's), Work Positioning and Fall-Arrest Devices not Manufactured by Sala (UCL) Advanced Products

Your Pole-Hoist system can be used as a support structure for various types of safety devices. Any accessories being used for the hoist MUST BE installed, inspected, maintained and operated according to the manufactures instructions. All installations MUST BE approved to local standards by a qualified engineer.

E) Inspection of Equipment Prior to Use

- Check all structural parts for damage: dents, cracked welds bend or crushed tubes. Minor cosmetic damage will not affect the structural integrity of the hoist, but any seriously damaged parts MUST BE repaired or replaced before using the hoist.

- Check all hardware ( pins, tri-screws, adjuster screws, nuts, bolts, pulleys, rollers and winch brackets) for damaged threads, bend, damaged or missing fasteners, loose fasteners. Check all pulleys and rollers for chips, grooves and excessive wear. Ensure that all pulleys and rollers turn freely.

- Inspect all equipment for missing, damaged or otherwise illegible warning stickers. Any damaged, missing or otherwise illegible stickers MUST BE replaced before using hoist.

- If you are using UCL Safety Systems Winches with your hoist, inspect the winch and cable as outlined in the "maintenance and inspection" section of the Digital Series Winch operators manual.

- Any additional winches, self-retracting lifelines (SRL's), work positioning or fall-arrest equipment being used with your UCL Safety Systems Hoist MUST BE installed, inspected, maintained and operated according to the manufactures instruction.

- Report any problems with the equipment to your supervisor and DO NOT USE the equipment until it has been repaired or replaced.

Pricing

Availability

Usually 3-5 Working Days

The Advanced Pole Hoist attaches with a carabiner on the universal bracket to a suitable anchor point, allowing you to work in any direction from any angle. The Advanced Pole Hoist has a unique swivel head that rotates 360 degrees, providing unparalleled flexibility in both vertical and horizontal confined-space entries. Overall length adjusts from either 4’ - 7’ (1.2 m - 2.13 m) or 6’ - 10’ (1.8 m - 3.05 m) for positioning attendant for working in close quarters. Custom Pole Hoist sizes are available.

The Advanced Pole Hoist attaches with a carabiner on the universal bracket to a suitable anchor point, allowing you to work in any direction from any angle. The Advanced Pole Hoist has a unique swivel head that rotates 360 degrees, providing unparalleled flexibility in both vertical and horizontal confined-space entries. Overall length adjusts from either 4’ - 7’ (1.2 m - 2.13 m) or 6’ - 10’ (1.8 m - 3.05 m) for positioning attendant for working in close quarters. Custom Pole Hoist sizes are available.Advanced 4’ - 7’ (1.2m - 2.13m) Extendable Pole Hoist.

| Model | Description |

| 8510409 | 4’-7’ (1.2 m - 2.13 m) Extendable Pole Hoist, swivel head & hardware. Includes winch bracket. |

| 8516303 | 4’-7’ (1.2 m - 2.13 m) Extendable Pole Hoist, swivel head & stainless steel hardware. Includes winch bracket. |

| Weight: 12 lbs (5.4 kg) | |

Advanced 6’ - 10’ (1.8 m - 3.05 m) Extendable Pole Hoist.

| Model | Description |

| 8510476 | 6’-10’ (1.8 m - 3.05 m) Extendable Pole Hoist, swivel head & hardware. Includes winch bracket. |

| 8520869 | 6’-10’ (1.8 m - 3.05 m) Extendable Pole Hoist, swivel Head & stainless steel hardware. Includes winch bracket. |

| Weight 14 lbs (6.4 kg) | |

The lightweight Pole Hoist is an extremely versatile piece of confined space entry / retrieval and rescue equipment. Simply attch via carabiner and the universal attachment ring to a suitable anchor point to work in ant direction from any angle. Overall length adjusts 1.8m to 3m (6' - 10' ft). For positioning personnel or working in confined space. Designed for use with Sala (UCL) safety systems winches.

Powder coated welded aluminum construction with zinc plated steel hardware.

Mounting Requirements

Anchor points for the pole hoist must be capable of withstanding a minimum load of 907 kg (2000 lbs) 4.4 KN.

General Specifications

| Specifications | kg | lbs |

| Rated Capacity (working load) | 204kg | 450lbs |

| Max. Allowed arresting force (M.A.F) rating for retractable devices ro shock absorbers | 453.6kg (4.4kn) | 1000lbs |

| Proof Load | 907kg | 2000lbs |

| Proof Test | UCT-133 | |

| Weight | ||

| Pole Hoist | 6.3kg | 14lbs |

| T-Bar Leg Assembly | 3kg | 7lbs |

Dimensions

| Material and Construction | |

| General Construction | Welded Aluminum / Steel |

| Weld Certification | CWB-47.2, CWB-47.1 |

| Base Material | 6061-T6, 5052 Aluminum |

| Sleeve | 6061-T6 Aluminum |

| Hardware | GR.5/GR.8 Steel, Zinc Plated |

| Finish | Gray Powder Coat |

A) Setting up the Pole Hoist

- Remove all parts from strorage / transport bags

containers etc. and layout on ground. - Remove Pin (1) from T-bar leg assembly (2),

rotate leg and replace pin. Remove Pin(3)

from T-bar leg assembly rotate foot assembly and replace pin. - Remove Pin(4) to adjust T-bar leg assembly to a comfortable height

for winch operation.

B) Winch and Cable Routing Installation

- Install winch with upper slot in back plate (4) over hook

on flat quick mount plate (5). - Swing winch in and down so that the mounting stud (6)

engages the hole in the winch carrying handle (7). - Thread clamp knob (8) onto stud (6) and tighten securely

by hand. - Pay out 5' to 10' of cable from winch, maintaining at least

10 lb. (5 kg) of tension on cable at all times. - Remove cable roller pin (9) & guide pulley (10) from pole

hoist mast assembly (11). Place cable under guide pulley

and replace guide pulley & cable roller pin. - Rotate pole hoist head assembly (12) so that slots

through head align. Place cable through slot in head

assembly and over pulley and around cable retainer

spring (13).

C) Pole Hoist Installation to Rated Anchor Point

- Using hanger bracket(1) on top pulley assembly (2), hang pole hoist using certified anchorage point and certified hardware.

- Make sure the T-bar leg(3) assembly is as vertical as possible to

support the weight of winch while in use.

D) Installation of Winches, Self-Retracting Lifelines (SLR's), Work Positioning and Fall-Arrest Devices not Manufactured by Sala (UCL) Advanced Products

Your Pole-Hoist system can be used as a support structure for various types of safety devices. Any accessories being used for the hoist MUST BE installed, inspected, maintained and operated according to the manufactures instructions. All installations MUST BE approved to local standards by a qualified engineer.

E) Inspection of Equipment Prior to Use

- Check all structural parts for damage: dents, cracked welds bend or crushed tubes. Minor cosmetic damage will not affect the structural integrity of the hoist, but any seriously damaged parts MUST BE repaired or replaced before using the hoist.

- Check all hardware ( pins, tri-screws, adjuster screws, nuts, bolts, pulleys, rollers and winch brackets) for damaged threads, bend, damaged or missing fasteners, loose fasteners. Check all pulleys and rollers for chips, grooves and excessive wear. Ensure that all pulleys and rollers turn freely.

- Inspect all equipment for missing, damaged or otherwise illegible warning stickers. Any damaged, missing or otherwise illegible stickers MUST BE replaced before using hoist.

- If you are using UCL Safety Systems Winches with your hoist, inspect the winch and cable as outlined in the "maintenance and inspection" section of the Digital Series Winch operators manual.

- Any additional winches, self-retracting lifelines (SRL's), work positioning or fall-arrest equipment being used with your UCL Safety Systems Hoist MUST BE installed, inspected, maintained and operated according to the manufactures instruction.

- Report any problems with the equipment to your supervisor and DO NOT USE the equipment until it has been repaired or replaced.

You May Also Like

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.