-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Fibre Lifting Slings

- Chain Slings & Components

- Lifting and Lashing Chain

- Wire Rope Slings & Assemblies

- Shackles

- Eye Bolts and Eye Nuts

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Runway Beam Monorail Crane Trolleys, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms and Jib Cranes

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

- Man-riding Hoists & Rescue Winches

-

Fall Arrest & Man-riding Systems

- Fall Arrest Davit Arms & Posts for Working at Height

- Sala Advanced Davit Arm Systems and Components

- Xtirpa Confined Space Davit Arm Systems and Components

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding & Rescue Tripods & Quadpods

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

- Home/

- Lifting Equipment/

- Chain Hoists; Manual, Electric, Air/

- Hand Chain Blocks/

- Atex Manual Chain Blocks/

- Kito "RCB Series" Atex Hand Chain Block

Kito "RCB Series" Atex Hand Chain Block

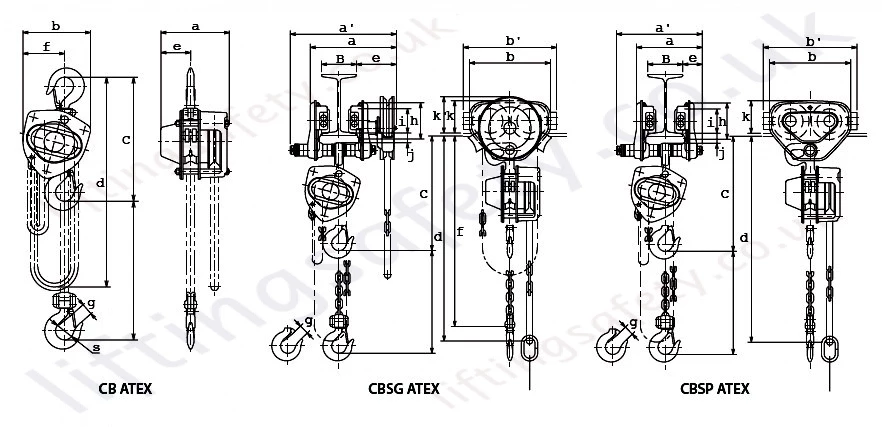

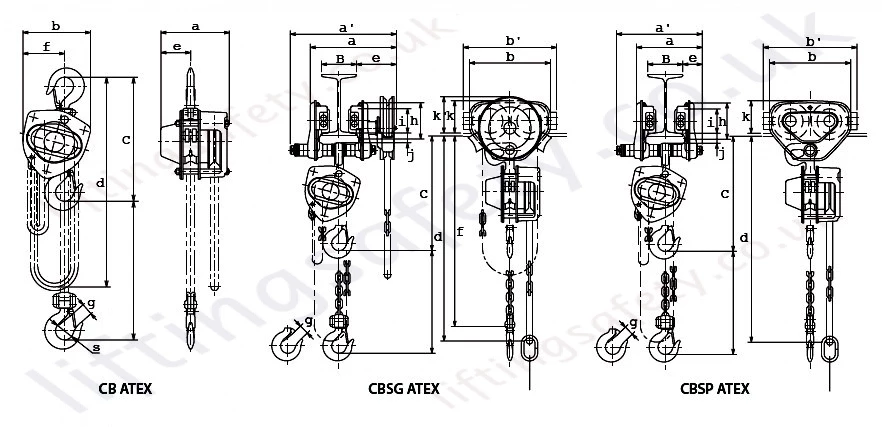

Spark-resistant hand chain hoist with optional hook, plain push trolley or geared travel trolley suspension.

RCB / KCSS-4184

Manufacturing Standard: ATEX 94/9/EC Safety Standard

Perfect for environments with combustible gases, vapors, and dusts. Kito's RCB Series Spark-Resistant Hand Chain Hoist is designed for petroleum, gas, pharmaceutical, and food industries - or any environment where safety is improved by the use of anti-sparking equipment.

Features

- Safety improved by modifications to industry leading steel-body M3CB hand chain hoist

- Uses oversize hoist bodies (ie. 1t RCB uses 1.5t M3CB hoist body)

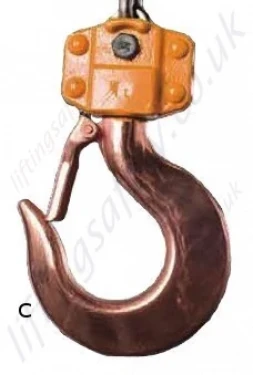

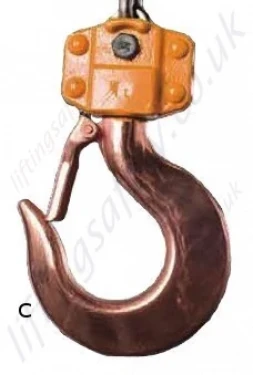

- Copper plated bottom hook

- Nickel-plated load chain

- Stainless-steel hand chain

- Solid bronze trolley wheels up to 2t models

- Bronze plated trolley wheels on 3t model

- Conforms to ATEX directive 94/9/EC

- Specification: EX II 2G c IIB T4 and EX II 2D c T135

- Operate safely up to 135°C

Standards

- ATEX 94/9/EC Safety Standard

- EX II 2G c IIB T4

- X II 2D c T135

- ASME B30.16 Safety Standard

- ASME HST-2 Performance Standard

- 125% of rated capactity test load

- Grade 100 Chain

ATEX Directive 94/9/EC

|

|

| A) Solid Bronze (Bronze coated for 3,000kg) B) Hand Chain SUS 304 |

C) Copper-coated load hook |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dimensions (mm)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Atex regulations as follows: The Atex directive on “use” refers to the DSEAR Regulations 2002 requires employers to protect workers from the risk of explosive atmospheres. An explosive atmosphere is defined as a mixture with air, under atmospheric conditions, of dangerous substances in the form of gases, vapours, mist or dust in which after ignition has occurred, combustion spreads to the entire unburned mixture. The Atex directive on “Product” refers to Directive 94/9/EC (ATEX 95) Equipment and Protective Systems for use in potentially explosive atmospheres. Covers electrical and non-electrical products intended for use in hazardous areas (gas, vapours or dust atmospheres) ATEX 95 implemented in the UK as: The Equipment and Protective Systems Intended for USE in Potentially Explosive Atmospheres Regulations 1996 Statutory Instrument 1996 No. 192.

Relevant EN Standards for potentially explosive areas of work

- EN 60079-17 Inspection and maintenance of electrical installations in hazardous areas (other than mines).

- EN 60079-10 Classification of Hazardous areas (Gas).

- EN 60079-14 Electrical Installations in Hazardous areas (other than mines)

- EN 60079-19 Repair and overhaul for apparatus used in explosive atmosphere (other than mines)

- EN 61241-3 Classification of areas where combustible dusts are or may be present.

- EN 1127-1 Explosion Prevention and Protection Basic concepts and methodology.

DSEAR (Dangerous Substances & Explosive Atmosphere Regulations) applies to all dangerous substances at nearly every business in Great Britain and gives the least requirements for protecting employees from fire and “explosion risks”, “dangerous substances” & “potentially explosive” atmospheres.

The main requirement are given below (summary).

- A risk assessment of any work place when dangerous substances are involved (potentially explosive)

- Eliminate or reduce to (as is reasonably practical) by the use of technical and organisational measures all of the Identified risks in potentially explosive areas or work

- Anti sparking, spark proof Equipment and other equipment should be provided by the employer and procedures documented to deal with accidents and emergencies before commencing work

- Training shall be provided to all employees to ensure that they are competent in all aspects of work including the use of Atex hoists and other items of Atex lifting equipment, Always follow the manufacturer’s operation user manual on safe use and maintenance.

- Classify places, areas at the work place where explosive atmospheres may occur (Inc potentially explosive areas) into zones, and mark the zones where necessary.

The Dangerous Substances & Explosive Atmosphere Regulations applies whenever there is work being carried out by an employer or self-employed person or a dangerous substance is present or liable to be present at the workplace or if the dangerous substance presents a risk to the safety of persons (as opposed to a risk to health). The warning signs for places where explosive atmospheres may occur (Distinctive features) are a Triangular shape and black letters on yellow background with black edging (the yellow part to take at least 50% of the area of the sign).

ATEX & Intrinsic Safety Information - Explosive Atmospheres

Protection Concepts

| ZONE | HAZARD | PROTECTION CONCEPTS |

| 0 | In which an explosive gas/air mixture is continuously present for long periods | Exia or Exs |

| 1 | In which an explosive gas/air mixture is likely to occur in normal operation. | Exd. Exe, Exib, Exp, Exia, Exs |

| 2 | In which an explosive gas/air mixture is not likely to occur in normal operation. | All concepts suitable for Zone 0 & 1, ExN, ExO and Exq |

Standards For Methods Of Protection

| METHOD OF PROTECTION | PERMITTED ZONE OF USE IN UK | CODE LETTER IEC, EX.., CENELEC, EEX |

| General requirement | - | - |

| Oil immersion | 2 | o |

| Pressurisation | 1 or 2 | p |

| Powder filling | 2 | q |

| Flameproof | 1 or 2 | d |

| Increased safety | 1 or 2 | e |

| Intrinsic safety | * 0, 1 or 2 | ia or ib |

| Non-incendive | 2 | n # |

| Encapsulation | 1 or 2 | m |

| Special | 1 or 2 | s |

| * ia: Zone 0,1,2. ib: Zone 1,2. not Zone 0. # n: used locally in UK. | ||

Gas Grouping and Temperature Classification

| Gas Grouping | Temperature Classification | |||

| GAS # GROUP CENELEC EN 50 014, IEC | REPRESENTATIVE GAS | T Class / IEC 79-7 | Max. surface temp ° C | |

| I * (mining) | Methane | T1 | 450 ° C | |

| IIA | Propane | T2 | 300 ° C | |

| IIB | Ethylene | T3 | 200 ° C | |

| IIC | Hydrogen | T4 | 135 ° C | |

| T5 | 100 ° C | |||

| T6 | 85 ° C | |||

Certification Code

(CENELEC marking information - example [EEx ia] IIC T4)

| [ | E | Ex | ia | ] | IIC | T4 |

| Associated apparatus* | Certified to the CENELEC standard | Explosion protected | Protection concept (IS) | Associated apparatus* | Apparatus group (gas group) | Temperature classification (not Gp I) |

| * (located in safe area and may be connected to hazardous area) | ||||||

Device Group & Category

| DEVICE GROUP | DEVICE CATEGORY | ZONE |

| I | M = mining | – |

| Mining | M 1 | – |

| Pit gas &/or flammable dusts | M 2 | – |

| II | G = gas | |

| Other areas | 1 G | 0, 1, 2 |

| Explosive atmosphere | 2 G | 1, 2 |

| 3 G | 2 | |

| D is added after G in the certification class number | D = dust | |

| (i.e. GD) if device is dust category approved also | 1 D | 20, 21, 22 |

| 2 D | 21, 22 | |

| 3 D | 22 | |

|

Explanation of the categories:

Note: A number in brackets before device category designation signifies that the device meets the requirements of an additional category to the main one that is specified. Example: II (1) 2G signifies that the device meets requirements for both 1 G and 2 G categories |

||

Characteristics of Substances

Flashpoint

This is the lowest temperature at which a liquid generates sufficient vapour to support ignition. This vapour can be ignited in many ways including temperature or energy (i.e. a spark)

Ignition Temperature

This is the lowest temperature at which the vapour will be ignited.

This defines the temperature class.

Classification of maximum surface temperatures of electrical apparatus (CENELEC)

| Temp. Class | Max. Surface Temp. |

| T1 | <450ºC |

| T2 | <300ºC |

| T3 | <200ºC |

| T4 | <135ºC |

| T5 | <100ºC |

| T6 | <85ºC |

Apparatus Group (energy ignition)

All surface industry gases/vapours are classed as Group II gases.

Group II is divided into 3 sub groups:

- IIA – High energy is required to ignite. Less intense explosion. (Propane)

- IIB – Less energy is required to ignite. More intense explosion. (Ethylene)

- IIC – Little energy is required to ignite. Most intense explosion. (Hydrogen)

Characteristics of some common flammable materials

| Gas/Vapour | Flashpoint | Gas Group | Ignition Temp. | Temp. Class |

| Acetone | 19ºC | IIA | 535ºC | T1 |

| Butane | -60ºC | IIA | 365ºC | T2 |

| Heptane | -4C | IIA | 215ºC | T3 |

| Ethyl Methyl Ether | 37ºC | IIB | 190ºC | T4 |

Note: There is no connection between ignition energy and ignition temperature

The information offered by LiftingSafety is guidance only. For detailed information see the relevant directives and regulations.

Pricing

Perfect for environments with combustible gases, vapors, and dusts. Kito's RCB Series Spark-Resistant Hand Chain Hoist is designed for petroleum, gas, pharmaceutical, and food industries - or any environment where safety is improved by the use of anti-sparking equipment.

Features

- Safety improved by modifications to industry leading steel-body M3CB hand chain hoist

- Uses oversize hoist bodies (ie. 1t RCB uses 1.5t M3CB hoist body)

- Copper plated bottom hook

- Nickel-plated load chain

- Stainless-steel hand chain

- Solid bronze trolley wheels up to 2t models

- Bronze plated trolley wheels on 3t model

- Conforms to ATEX directive 94/9/EC

- Specification: EX II 2G c IIB T4 and EX II 2D c T135

- Operate safely up to 135°C

Standards

- ATEX 94/9/EC Safety Standard

- EX II 2G c IIB T4

- X II 2D c T135

- ASME B30.16 Safety Standard

- ASME HST-2 Performance Standard

- 125% of rated capactity test load

- Grade 100 Chain

ATEX Directive 94/9/EC

|

|

| A) Solid Bronze (Bronze coated for 3,000kg) B) Hand Chain SUS 304 |

C) Copper-coated load hook |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dimensions (mm)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Atex regulations as follows: The Atex directive on “use” refers to the DSEAR Regulations 2002 requires employers to protect workers from the risk of explosive atmospheres. An explosive atmosphere is defined as a mixture with air, under atmospheric conditions, of dangerous substances in the form of gases, vapours, mist or dust in which after ignition has occurred, combustion spreads to the entire unburned mixture. The Atex directive on “Product” refers to Directive 94/9/EC (ATEX 95) Equipment and Protective Systems for use in potentially explosive atmospheres. Covers electrical and non-electrical products intended for use in hazardous areas (gas, vapours or dust atmospheres) ATEX 95 implemented in the UK as: The Equipment and Protective Systems Intended for USE in Potentially Explosive Atmospheres Regulations 1996 Statutory Instrument 1996 No. 192.

Relevant EN Standards for potentially explosive areas of work

- EN 60079-17 Inspection and maintenance of electrical installations in hazardous areas (other than mines).

- EN 60079-10 Classification of Hazardous areas (Gas).

- EN 60079-14 Electrical Installations in Hazardous areas (other than mines)

- EN 60079-19 Repair and overhaul for apparatus used in explosive atmosphere (other than mines)

- EN 61241-3 Classification of areas where combustible dusts are or may be present.

- EN 1127-1 Explosion Prevention and Protection Basic concepts and methodology.

DSEAR (Dangerous Substances & Explosive Atmosphere Regulations) applies to all dangerous substances at nearly every business in Great Britain and gives the least requirements for protecting employees from fire and “explosion risks”, “dangerous substances” & “potentially explosive” atmospheres.

The main requirement are given below (summary).

- A risk assessment of any work place when dangerous substances are involved (potentially explosive)

- Eliminate or reduce to (as is reasonably practical) by the use of technical and organisational measures all of the Identified risks in potentially explosive areas or work

- Anti sparking, spark proof Equipment and other equipment should be provided by the employer and procedures documented to deal with accidents and emergencies before commencing work

- Training shall be provided to all employees to ensure that they are competent in all aspects of work including the use of Atex hoists and other items of Atex lifting equipment, Always follow the manufacturer’s operation user manual on safe use and maintenance.

- Classify places, areas at the work place where explosive atmospheres may occur (Inc potentially explosive areas) into zones, and mark the zones where necessary.

The Dangerous Substances & Explosive Atmosphere Regulations applies whenever there is work being carried out by an employer or self-employed person or a dangerous substance is present or liable to be present at the workplace or if the dangerous substance presents a risk to the safety of persons (as opposed to a risk to health). The warning signs for places where explosive atmospheres may occur (Distinctive features) are a Triangular shape and black letters on yellow background with black edging (the yellow part to take at least 50% of the area of the sign).

ATEX & Intrinsic Safety Information - Explosive Atmospheres

Protection Concepts

| ZONE | HAZARD | PROTECTION CONCEPTS |

| 0 | In which an explosive gas/air mixture is continuously present for long periods | Exia or Exs |

| 1 | In which an explosive gas/air mixture is likely to occur in normal operation. | Exd. Exe, Exib, Exp, Exia, Exs |

| 2 | In which an explosive gas/air mixture is not likely to occur in normal operation. | All concepts suitable for Zone 0 & 1, ExN, ExO and Exq |

Standards For Methods Of Protection

| METHOD OF PROTECTION | PERMITTED ZONE OF USE IN UK | CODE LETTER IEC, EX.., CENELEC, EEX |

| General requirement | - | - |

| Oil immersion | 2 | o |

| Pressurisation | 1 or 2 | p |

| Powder filling | 2 | q |

| Flameproof | 1 or 2 | d |

| Increased safety | 1 or 2 | e |

| Intrinsic safety | * 0, 1 or 2 | ia or ib |

| Non-incendive | 2 | n # |

| Encapsulation | 1 or 2 | m |

| Special | 1 or 2 | s |

| * ia: Zone 0,1,2. ib: Zone 1,2. not Zone 0. # n: used locally in UK. | ||

Gas Grouping and Temperature Classification

| Gas Grouping | Temperature Classification | |||

| GAS # GROUP CENELEC EN 50 014, IEC | REPRESENTATIVE GAS | T Class / IEC 79-7 | Max. surface temp ° C | |

| I * (mining) | Methane | T1 | 450 ° C | |

| IIA | Propane | T2 | 300 ° C | |

| IIB | Ethylene | T3 | 200 ° C | |

| IIC | Hydrogen | T4 | 135 ° C | |

| T5 | 100 ° C | |||

| T6 | 85 ° C | |||

Certification Code

(CENELEC marking information - example [EEx ia] IIC T4)

| [ | E | Ex | ia | ] | IIC | T4 |

| Associated apparatus* | Certified to the CENELEC standard | Explosion protected | Protection concept (IS) | Associated apparatus* | Apparatus group (gas group) | Temperature classification (not Gp I) |

| * (located in safe area and may be connected to hazardous area) | ||||||

Device Group & Category

| DEVICE GROUP | DEVICE CATEGORY | ZONE |

| I | M = mining | – |

| Mining | M 1 | – |

| Pit gas &/or flammable dusts | M 2 | – |

| II | G = gas | |

| Other areas | 1 G | 0, 1, 2 |

| Explosive atmosphere | 2 G | 1, 2 |

| 3 G | 2 | |

| D is added after G in the certification class number | D = dust | |

| (i.e. GD) if device is dust category approved also | 1 D | 20, 21, 22 |

| 2 D | 21, 22 | |

| 3 D | 22 | |

|

Explanation of the categories:

Note: A number in brackets before device category designation signifies that the device meets the requirements of an additional category to the main one that is specified. Example: II (1) 2G signifies that the device meets requirements for both 1 G and 2 G categories |

||

Characteristics of Substances

Flashpoint

This is the lowest temperature at which a liquid generates sufficient vapour to support ignition. This vapour can be ignited in many ways including temperature or energy (i.e. a spark)

Ignition Temperature

This is the lowest temperature at which the vapour will be ignited.

This defines the temperature class.

Classification of maximum surface temperatures of electrical apparatus (CENELEC)

| Temp. Class | Max. Surface Temp. |

| T1 | <450ºC |

| T2 | <300ºC |

| T3 | <200ºC |

| T4 | <135ºC |

| T5 | <100ºC |

| T6 | <85ºC |

Apparatus Group (energy ignition)

All surface industry gases/vapours are classed as Group II gases.

Group II is divided into 3 sub groups:

- IIA – High energy is required to ignite. Less intense explosion. (Propane)

- IIB – Less energy is required to ignite. More intense explosion. (Ethylene)

- IIC – Little energy is required to ignite. Most intense explosion. (Hydrogen)

Characteristics of some common flammable materials

| Gas/Vapour | Flashpoint | Gas Group | Ignition Temp. | Temp. Class |

| Acetone | 19ºC | IIA | 535ºC | T1 |

| Butane | -60ºC | IIA | 365ºC | T2 |

| Heptane | -4C | IIA | 215ºC | T3 |

| Ethyl Methyl Ether | 37ºC | IIB | 190ºC | T4 |

Note: There is no connection between ignition energy and ignition temperature

The information offered by LiftingSafety is guidance only. For detailed information see the relevant directives and regulations.

Products of Possible Interest

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.