-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Soft Lifting Slings

- Lifting Chain Slings

- Wire Rope Slings & Assemblies

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Beam Trolleys and Crane Bridges, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

-

Confined Space and Rescue Systems

- Xtirpa Confined Space Davit Arm Systems and Components

- Sala Advanced Davit Arm Systems and Components

- Genesi Confined Space Systems

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding Hoists & Rescue Winches

- Fall Arrest & Rescue Tripods

- Fall Arrest Davit Arms & Posts for Working at Height

-

Fall Arrest & Man-riding Systems

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

- Home/

- Lifting Equipment/

- Access and Safety Related Equipment/

- Load Arrestors/

- LiftingSafety Load Arrestors upto 3000kg/

- LiftingSafety Load Arrestor - Range from 300kg to 3000kg (20 Options)

LiftingSafety Load Arrestor - Range from 300kg to 3000kg (20 Options)

High quality UK manufactured load arresters with many cable length options.

SELS Load Arrestors / LA-2653

Load Arrestor Information

Load arrestors are designed as fall protection for materials and serve a similar purpose to a sala fall arrest inertia reel as used for personal fall protection. The load arrestor, connected to a load, will stop a fall should it occur. The load arrestor will not only protect equipment attached to it, but also people and other items under the suspended equipment. The load arrestor is attached to a structure via the bolt holes. The equipment to be protected is to be attached to the wire rope. The wire rope is kept under tension and is automatically rewound on the wire rope drum. A drum spring will keep the wire rope under tension. If a fall occurs, a ratchet pawl will engage with a ratchet ring, when the wire speed exceeds 0.5 m/sec. The ratchet ring is then screwed into the cover and compresses the brake disc until all energy has been absorbed and the equipment safely held, undamaged by the wire rope. The brake disc also pushes the indication pin through the cover. The indication pin protruding by a few millimetres. This indicates that the load arrestor should immediately be removed, serviced, and have the brake reset.

Small Load Arrestor

Medium Load Arrestor

Large Load Arrestors

Features

- The Load arrestor provides independent protection that will arrest the fall of a load in the event of the primary system failing and, as it is completely independent of the primary lifting system, it lowers the risk of equipment damage and protects workers in and around the area of the incident.

- This range of load arrestors comes with safe working loads between 300kg and 3000kg, with a variety of wire cable lengths and arrest speeds.

- The load arrestor is installed adjacent to the primary lifting device and fixed to a suitable anchorage point. Its retractable steel cable is then secured to the load. The wire rope is attached to the arrestor using an internal spring-loaded drum that keeps the rope under a constant light tension yet allows unrestricted movement of the protected load.

- If the primary lifting device fails, and the load begins to fall, the sala arrestor senses a descent speed in excess of the set arrest speed and automatically engages an internal inertia-activated mechanical brake that acts on the rope drum. This arrests the fall over a short distance to reduce the shock forces exerted on the load and the load arrestor.

- Our range of load arrestors are only designed for indoor use.

- All Sala load arrestor standard units operate at a speed of 0.5 metres per second but there is choice of 0.3 and 1.0 metres per second operation but this needs to be stated at time of order. (Only 0.5 and 1.0 metres per second activation springs are available on the medium and large range)

Servicing the Load Arrestor

Servicing should be carried out at 12 monthly intervals based on a standard working week with up to 60 cycles a day, but should not exceed 7000 cycles before servicing. This should be based on the users risk assessment, taking into account environmental and working conditions etc..

Then the servicing periods should be reduced accordingly. If the unit has arrested a fall or if the activation pin (fall indicator) is protruding is should be withdrawn from service immediately.

Multiple Load Arrestors - To Increase Capacity

Small, Medium and Large

Under special circumstances sala multiple load arrestors can be used on a single application as confirmed by the manufacturer; tests have been carried out that proved that you can mount up to 4 load arrestors to a single item that requires fall protection (e.g. one for each corner), thus increasing the maximum potential arresting capacity. This works because there is a variance in the stopping distance, so all 4 units would work as designed.As the ratchet pawls will notengage simultaneously in two load arrestors, it is vital that the sala Load Arrestor are installed at a sufficient distance apart with unrestricted vertical movement under each unit to enable the falling force to be properly devided between them. Please contact our technical representatives before appyling this installation procedure.

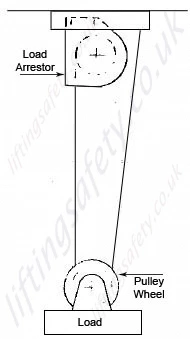

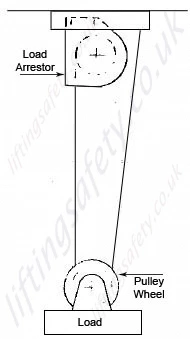

Load Arrestor used with a Pulley Sheave - For Increased Capacity

Small, Medium and Large

Combined with Pulley

The load arrestor can be combined with a pulley and can if properly installed, protect twice the nominal load but with half wire length capacity. The load arrestor must for this application be ordered complete with pulleyand modified ratchet pawl springs to maintain engagement speed of O.5m/s. The wire rope should move in the same direction on both the wire drum and the external pulley.

Pulley in Cramp Conditions

The sala Load Arrestor can be used in cramped conditions by using a pulley as shown below. The LoadArrestor must under all circumstances be installed so the wire drum is working vertically. For this application, the anchorage point for the external pulley must be calculated according to the specification table below.

All units have to have a vertical feed to the unit although you can put the wire on a pulley so that it will work if an arc is required but will keep the feed vertical to the unit. In that case it would not halve the load or speed as you are only ensuring that the cable runs vertically.

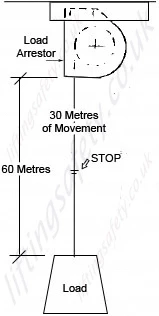

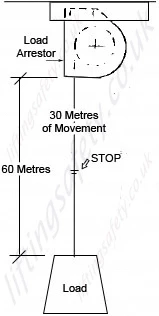

Load Arrestors with Long Cable Lengths

If a customer requires a unit that has 60 metres of cable though only 30 metres ever needs to be recoiled inside the unit, this can be achieved by putting a clamp on the wire to keep the 30 metres from entering the unit. The only factor is that the recoil spring must be able to cope with the extra weight of the wire, I will do some tests and get you the maximum lengths that can be left outside the housing. (See image to the right)

Main Features

- Independent protection.

- Reduces the risk of equipment damage and protects personnel.

- Three body sizes, small, medium, and large.

- Protect loads from 300kg up to 3000kg.

- Variety of standard cable lengths (other specials available on request).

- Allows unrestricted movement of the protected load.

- Senses a fall speed and automatically engages.

- Arrests falling materials over a short distance.

- Absorbs the shock forces.

Applications

The Load Arrestors can be used in conjunction with a large variety of lifting devices, or protection of overhead loads:

- Cranes

- Hoists

- Lifts

- Lighting rigs

- Tools / equipment

Options Available

| Model | Body Size | Capacity | Minimum Load (kg) | Cable Length (m) | Brake Activating Speed (m/s) | Rope Dia. (mm) | Rope M.B.S. (kN) | Max Stopping Distance (mm) | Minimum Anchorage Capability (kN) | Maximum cycles per day | Maximum cycles between servicing | Approx. Dimensions (mm) | Weight (kg) |

| SELS-300-12 | Small | 300kg | 2.5 | 12 (1- fall) | 0.5 std (0.33 or 1 - special) | 5 | 16.0 | 1000 | 15.8kN | TBA | TBA | 200 x 260 x 112 | 8.5 |

| SELS-400-8 | Small | 400kg | 2.5 | 8 (1- fall) | 0.5 std (0.33 or 1 - special) | 6 | 24.0 | 1000 | 22.8kN | TBA | TBA | 200 x 260 x 112 | 8.5 |

| SELS-500-5 | Small | 500kg | 2.5 | 5 (1- fall) | 0.5 std (0.33 or 1 - special) | 7 | 32.0 | 1000 | 31.0kN | TBA | TBA | 200 x 260 x 112 | 8.5 |

| SELS-500-20 | Medium | 500kg | 5 to 7.5 | 20 (1- fall) | 0.5 std (1 -special) | 7 | 32.0 | 600 | 31.0kN | TBA | TBA | 368 x 435 x 236 |

41 |

| SELS-600-6P | Small | 600kg | 2.5 | 6 (2- fall c/w pulley) | 0.5 | 5 | 16.0 | 1000 | 15.8kN x2 (31.6kN) | TBA | TBA | 200 x 260 x 112 | 8.5 |

| SELS-800-4P | Small | 800kg | 2.5 | 4 (2- fall c/w pulley) | 0.5 | 6 | 24.0 | 1000 | 22.8kN x2 (45.6kN) | TBA | TBA | 200 x 260 x 112 | 8.5 |

| SELS-800-17 | Medium | 800kg | 5 to 7.5 | 17 (1- fall) | 0.5 std (1m/s - special) | 8 | 41.0 | 600 | 40.5kN | TBA | TBA | 368 x 435 x 236 | 41 |

| SELS-1000-2.5P | Small | 1000kg | 2.5 | 2.5 (2- fall c/w pulley) | 0.5 | 7 | 32.0 | 1000 | 31.0kN x2 (62.0kN) | TBA | TBA | 200 x 260 x 112 | 8.5 |

| SELS-1000-10P | Medium | 1000kg | 5 to 7.5 | 10 (2- fall c/w pulley) | 0.5 | 7 | 32.0 | 500 | 31.0kN x2 (62.0kN) | TBA | TBA | 368 x 435 x 236 | 41 |

| Model | Body Size | Capacity | Minimum Load (kg) | Cable Length (m) | Brake Activating Speed (Arrest Speed)(m/s) | Rope Dia. (mm) | Rope M.B.S. (kN) | Max Stopping Distance (mm) | Minimum Anchorage Capability (kN) | Maximum cycles per day | Maximum cycles between servicing | Approx. Dimensions (mm) | Weight (kg) |

| SELS-1000-12 | Medium | 1000kg | 5 to 7.5 | 12 (1- fall) | 0.5 std (1m/s - special) | 9 | 48.0 | 800 | 51.0kN | TBA | TBA | 368 x 435 x 236 | 41 |

| SELS-1000-14.3 | Medium | 1000kg | 5 to 7.5 | 14.3 (1- fall) | 0.5 std (1 - special) | 11 | 71.0 | 500 | 51.0kN | TBA | TBA | 368 x 435 x 236 | 41 |

| SELS-1000-30 | Large | 1000kg | 15 | 30 (1- fall) | 0.5 std (1 - special) | 9 | 48 | 800 | TBA | TBA | TBA | 470 x 535 x 220 | 105 |

| SELS-1300-20 | Large | 1300kg | 15 | 20 (1- fall) | 0.5 std (1 - special) | 10 | 59 | 800 | TBA | TBA | TBA | 470 x 535 x 220 | 105 |

| SELS-1500-5 | Medium | 1500kg | TBA | 5 (1-fall) | 0.5 std (1 - Special) | 11 | 71 | 500 | TBA | TBA | TBA | 368 x 435 x 236 | 41 |

| SELS-1500-15 | Large | 1500kg | 15 | 15 (1- fall) | 0.5 std (1 - special) | 11 | 71 | 1000 | TBA | TBA | TBA | 470 x 535 x 220 | 105 |

| SELS-1600-8.5P | Medium | 1600kg | 5 to 7.5 | 8.5 (2- fall c/w pulley) | 0.5 | 8 | 41.0 | 500 | 40.5kN x2 (81.0kN) | TBA | TBA | 368 x 435 x 236 | 41 |

| SELS-2000-6P | Medium | 2000kg | 5 to 7.5 | 6 (2- fall c/w pulley) | 0.5 | 9 | 48.0 | 500 | 51.0kN x2 (102.0kN) | TBA | TBA | 368 x 435 x 236 | 41 |

| SELS-2000-7.15P | Medium | 2000kg | 5 to 7.5 | 7.15 (2-fall c/w pulley) | 0.5 | 11 | 71.0 | 500 | 51.0kN x2(102.0kN) | TBA | TBA | 368 x 435 x 236 | 41 |

| SELS-2000-15P | Large | 2000kg | 15 | 15 (2- fall c/w pulley) | 0.5 | 9 | 48 | 500 | TBA | TBA | TBA | 470 x 535 x 220 | 105 |

| SELS-2600-10P | Large | 2600kg | 15 | 10 (2- fall c/w pulley) | 0.5 | 10 | 59 | 500 | TBA | TBA | TBA | 470 x 535 x 220 | 105 |

| SELS-3000-2.5P | Medium | 3000kg | TBA | 2.5 (2-fall c/w pulley) | 0.5 | 11 | 71 | 500 | TBA | TBA | TBA | 368 x 435 x 236 | 41 |

| SELS-3000-7.5P | Large | 3000kg | 15 | 7.5 (2- fall c/w pulley) | 0.5 | 11 | 71 | 700 | TBA | TBA | TBA | 470 x 535 x 220 | 105 |

Pricing

Load Arrestor Information

Load arrestors are designed as fall protection for materials and serve a similar purpose to a sala fall arrest inertia reel as used for personal fall protection. The load arrestor, connected to a load, will stop a fall should it occur. The load arrestor will not only protect equipment attached to it, but also people and other items under the suspended equipment. The load arrestor is attached to a structure via the bolt holes. The equipment to be protected is to be attached to the wire rope. The wire rope is kept under tension and is automatically rewound on the wire rope drum. A drum spring will keep the wire rope under tension. If a fall occurs, a ratchet pawl will engage with a ratchet ring, when the wire speed exceeds 0.5 m/sec. The ratchet ring is then screwed into the cover and compresses the brake disc until all energy has been absorbed and the equipment safely held, undamaged by the wire rope. The brake disc also pushes the indication pin through the cover. The indication pin protruding by a few millimetres. This indicates that the load arrestor should immediately be removed, serviced, and have the brake reset.

Small Load Arrestor

Medium Load Arrestor

Large Load Arrestors

Features

- The Load arrestor provides independent protection that will arrest the fall of a load in the event of the primary system failing and, as it is completely independent of the primary lifting system, it lowers the risk of equipment damage and protects workers in and around the area of the incident.

- This range of load arrestors comes with safe working loads between 300kg and 3000kg, with a variety of wire cable lengths and arrest speeds.

- The load arrestor is installed adjacent to the primary lifting device and fixed to a suitable anchorage point. Its retractable steel cable is then secured to the load. The wire rope is attached to the arrestor using an internal spring-loaded drum that keeps the rope under a constant light tension yet allows unrestricted movement of the protected load.

- If the primary lifting device fails, and the load begins to fall, the sala arrestor senses a descent speed in excess of the set arrest speed and automatically engages an internal inertia-activated mechanical brake that acts on the rope drum. This arrests the fall over a short distance to reduce the shock forces exerted on the load and the load arrestor.

- Our range of load arrestors are only designed for indoor use.

- All Sala load arrestor standard units operate at a speed of 0.5 metres per second but there is choice of 0.3 and 1.0 metres per second operation but this needs to be stated at time of order. (Only 0.5 and 1.0 metres per second activation springs are available on the medium and large range)

Servicing the Load Arrestor

Servicing should be carried out at 12 monthly intervals based on a standard working week with up to 60 cycles a day, but should not exceed 7000 cycles before servicing. This should be based on the users risk assessment, taking into account environmental and working conditions etc..

Then the servicing periods should be reduced accordingly. If the unit has arrested a fall or if the activation pin (fall indicator) is protruding is should be withdrawn from service immediately.

Multiple Load Arrestors - To Increase Capacity

Small, Medium and Large

Under special circumstances sala multiple load arrestors can be used on a single application as confirmed by the manufacturer; tests have been carried out that proved that you can mount up to 4 load arrestors to a single item that requires fall protection (e.g. one for each corner), thus increasing the maximum potential arresting capacity. This works because there is a variance in the stopping distance, so all 4 units would work as designed.As the ratchet pawls will notengage simultaneously in two load arrestors, it is vital that the sala Load Arrestor are installed at a sufficient distance apart with unrestricted vertical movement under each unit to enable the falling force to be properly devided between them. Please contact our technical representatives before appyling this installation procedure.

Load Arrestor used with a Pulley Sheave - For Increased Capacity

Small, Medium and Large

Combined with Pulley

The load arrestor can be combined with a pulley and can if properly installed, protect twice the nominal load but with half wire length capacity. The load arrestor must for this application be ordered complete with pulleyand modified ratchet pawl springs to maintain engagement speed of O.5m/s. The wire rope should move in the same direction on both the wire drum and the external pulley.

Pulley in Cramp Conditions

The sala Load Arrestor can be used in cramped conditions by using a pulley as shown below. The LoadArrestor must under all circumstances be installed so the wire drum is working vertically. For this application, the anchorage point for the external pulley must be calculated according to the specification table below.

All units have to have a vertical feed to the unit although you can put the wire on a pulley so that it will work if an arc is required but will keep the feed vertical to the unit. In that case it would not halve the load or speed as you are only ensuring that the cable runs vertically.

Load Arrestors with Long Cable Lengths

If a customer requires a unit that has 60 metres of cable though only 30 metres ever needs to be recoiled inside the unit, this can be achieved by putting a clamp on the wire to keep the 30 metres from entering the unit. The only factor is that the recoil spring must be able to cope with the extra weight of the wire, I will do some tests and get you the maximum lengths that can be left outside the housing. (See image to the right)

Main Features

- Independent protection.

- Reduces the risk of equipment damage and protects personnel.

- Three body sizes, small, medium, and large.

- Protect loads from 300kg up to 3000kg.

- Variety of standard cable lengths (other specials available on request).

- Allows unrestricted movement of the protected load.

- Senses a fall speed and automatically engages.

- Arrests falling materials over a short distance.

- Absorbs the shock forces.

Applications

The Load Arrestors can be used in conjunction with a large variety of lifting devices, or protection of overhead loads:

- Cranes

- Hoists

- Lifts

- Lighting rigs

- Tools / equipment

Options Available

| Model | Body Size | Capacity | Minimum Load (kg) | Cable Length (m) | Brake Activating Speed (m/s) | Rope Dia. (mm) | Rope M.B.S. (kN) | Max Stopping Distance (mm) | Minimum Anchorage Capability (kN) | Maximum cycles per day | Maximum cycles between servicing | Approx. Dimensions (mm) | Weight (kg) |

| SELS-300-12 | Small | 300kg | 2.5 | 12 (1- fall) | 0.5 std (0.33 or 1 - special) | 5 | 16.0 | 1000 | 15.8kN | TBA | TBA | 200 x 260 x 112 | 8.5 |

| SELS-400-8 | Small | 400kg | 2.5 | 8 (1- fall) | 0.5 std (0.33 or 1 - special) | 6 | 24.0 | 1000 | 22.8kN | TBA | TBA | 200 x 260 x 112 | 8.5 |

| SELS-500-5 | Small | 500kg | 2.5 | 5 (1- fall) | 0.5 std (0.33 or 1 - special) | 7 | 32.0 | 1000 | 31.0kN | TBA | TBA | 200 x 260 x 112 | 8.5 |

| SELS-500-20 | Medium | 500kg | 5 to 7.5 | 20 (1- fall) | 0.5 std (1 -special) | 7 | 32.0 | 600 | 31.0kN | TBA | TBA | 368 x 435 x 236 |

41 |

| SELS-600-6P | Small | 600kg | 2.5 | 6 (2- fall c/w pulley) | 0.5 | 5 | 16.0 | 1000 | 15.8kN x2 (31.6kN) | TBA | TBA | 200 x 260 x 112 | 8.5 |

| SELS-800-4P | Small | 800kg | 2.5 | 4 (2- fall c/w pulley) | 0.5 | 6 | 24.0 | 1000 | 22.8kN x2 (45.6kN) | TBA | TBA | 200 x 260 x 112 | 8.5 |

| SELS-800-17 | Medium | 800kg | 5 to 7.5 | 17 (1- fall) | 0.5 std (1m/s - special) | 8 | 41.0 | 600 | 40.5kN | TBA | TBA | 368 x 435 x 236 | 41 |

| SELS-1000-2.5P | Small | 1000kg | 2.5 | 2.5 (2- fall c/w pulley) | 0.5 | 7 | 32.0 | 1000 | 31.0kN x2 (62.0kN) | TBA | TBA | 200 x 260 x 112 | 8.5 |

| SELS-1000-10P | Medium | 1000kg | 5 to 7.5 | 10 (2- fall c/w pulley) | 0.5 | 7 | 32.0 | 500 | 31.0kN x2 (62.0kN) | TBA | TBA | 368 x 435 x 236 | 41 |

| Model | Body Size | Capacity | Minimum Load (kg) | Cable Length (m) | Brake Activating Speed (Arrest Speed)(m/s) | Rope Dia. (mm) | Rope M.B.S. (kN) | Max Stopping Distance (mm) | Minimum Anchorage Capability (kN) | Maximum cycles per day | Maximum cycles between servicing | Approx. Dimensions (mm) | Weight (kg) |

| SELS-1000-12 | Medium | 1000kg | 5 to 7.5 | 12 (1- fall) | 0.5 std (1m/s - special) | 9 | 48.0 | 800 | 51.0kN | TBA | TBA | 368 x 435 x 236 | 41 |

| SELS-1000-14.3 | Medium | 1000kg | 5 to 7.5 | 14.3 (1- fall) | 0.5 std (1 - special) | 11 | 71.0 | 500 | 51.0kN | TBA | TBA | 368 x 435 x 236 | 41 |

| SELS-1000-30 | Large | 1000kg | 15 | 30 (1- fall) | 0.5 std (1 - special) | 9 | 48 | 800 | TBA | TBA | TBA | 470 x 535 x 220 | 105 |

| SELS-1300-20 | Large | 1300kg | 15 | 20 (1- fall) | 0.5 std (1 - special) | 10 | 59 | 800 | TBA | TBA | TBA | 470 x 535 x 220 | 105 |

| SELS-1500-5 | Medium | 1500kg | TBA | 5 (1-fall) | 0.5 std (1 - Special) | 11 | 71 | 500 | TBA | TBA | TBA | 368 x 435 x 236 | 41 |

| SELS-1500-15 | Large | 1500kg | 15 | 15 (1- fall) | 0.5 std (1 - special) | 11 | 71 | 1000 | TBA | TBA | TBA | 470 x 535 x 220 | 105 |

| SELS-1600-8.5P | Medium | 1600kg | 5 to 7.5 | 8.5 (2- fall c/w pulley) | 0.5 | 8 | 41.0 | 500 | 40.5kN x2 (81.0kN) | TBA | TBA | 368 x 435 x 236 | 41 |

| SELS-2000-6P | Medium | 2000kg | 5 to 7.5 | 6 (2- fall c/w pulley) | 0.5 | 9 | 48.0 | 500 | 51.0kN x2 (102.0kN) | TBA | TBA | 368 x 435 x 236 | 41 |

| SELS-2000-7.15P | Medium | 2000kg | 5 to 7.5 | 7.15 (2-fall c/w pulley) | 0.5 | 11 | 71.0 | 500 | 51.0kN x2(102.0kN) | TBA | TBA | 368 x 435 x 236 | 41 |

| SELS-2000-15P | Large | 2000kg | 15 | 15 (2- fall c/w pulley) | 0.5 | 9 | 48 | 500 | TBA | TBA | TBA | 470 x 535 x 220 | 105 |

| SELS-2600-10P | Large | 2600kg | 15 | 10 (2- fall c/w pulley) | 0.5 | 10 | 59 | 500 | TBA | TBA | TBA | 470 x 535 x 220 | 105 |

| SELS-3000-2.5P | Medium | 3000kg | TBA | 2.5 (2-fall c/w pulley) | 0.5 | 11 | 71 | 500 | TBA | TBA | TBA | 368 x 435 x 236 | 41 |

| SELS-3000-7.5P | Large | 3000kg | 15 | 7.5 (2- fall c/w pulley) | 0.5 | 11 | 71 | 700 | TBA | TBA | TBA | 470 x 535 x 220 | 105 |

You May Also Like

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.