-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Soft Lifting Slings

- Lifting Chain Slings

- Wire Rope Slings & Assemblies

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Beam Trolleys and Crane Bridges, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

-

Confined Space and Rescue Systems

- Xtirpa Confined Space Davit Arm Systems and Components

- Sala Advanced Davit Arm Systems and Components

- Genesi Confined Space Systems

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding Hoists & Rescue Winches

- Fall Arrest & Rescue Tripods

- Fall Arrest Davit Arms & Posts for Working at Height

-

Fall Arrest & Man-riding Systems

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

- Home/

- Lifting Equipment/

- Cranes; Mobile, Portable and Fixed/

- Portable Davit Arms/

- Vertical Type Davit Arms/

- Portable Light Weight, Vertical Pole Style Davit Arm With Many Options Built To Customers Specification - Range to 1000kg

Portable Light Weight, Vertical Pole Style Davit Arm With Many Options Built To Customers Specification - Range to 1000kg

Portable Lightweight Split Pole Davit Arm, Specials and Bespoke designs are available. Top quality made in the UK.

SPDA-1210

We offer several designs of lightweight portable davit lifting arms, including lean over type davits and vertical split pole type davits. The split pole davits are suited to applications where there is an obstruction which must be worked around, because the unit is relatively compact, it offers an excellent solution for a confined space or restricted access lifitng environments.

To help comply with the manual handling regulations our davit arms are made in three sections, this ensures that the davits are easily transportable when the davit is to be used in more than one location. They are supplied CE marked and come with a certificate of conformity. The design of the davits means that they are very portable. Many of our customers purchase several davit sockets, and permanently install these wherever they require the davit. One davit arm can then be purchased and easily transported between jobs - reducing the overall cost.

This type of light weight davit lifting arm is mainly manufactured from galvanized mild steel though can also be manufactured from aluminum or stainless steel if required. The galvanized steel arms are suitable for use in marine and offshore environments, whether this be for a lifting application in the offshore oil and gas industry, or for use on a boat. The aluminium option offers an even more lightweight solution. The Stainless Steel davit arms can be used in hazardous environments. These davits are often utilised in the petrochemical industry, where they are used in hazardous environments, and also the food industry, where regulations for cleanliness must be observed.

All of our special davit arm jib cranes can be manufactured to our customers specification (height of lift and reach). In order to maintain the integrity of the davit we recommend that for a Safe Working Load (SWL) of 500kg the radius (reach) does not exceed 1800mm; and for 1000kg 1200mm. The height to the lifting eye on the davit arm can be up to 3000mm. These figures are given as a rough guide. If your requirments do not fall within the advised parameters, please submit your required measurments, and we will quote the item or our suggested alternative that may meet your needs. If the reach of the davit arm you require exceeds our recomendations, but a lower safe working load is acceptable, then we could manufacture a bespoke davit arm that meets your requirments.

Our davit jib arms can be designed for the lifting of materials and / or for the lifting of people (manriding application). To view detailed specifications, information and options on our man-riding davits please click here. For general lifting applications the davit arm’s can be supplied up to 1000kg safe working load (SWL). For material lifting applications our Davits can be supplied with a manual hand winch, electric chain hoist, pneumatic hoists or hand chain block to suit your lifting needs and environment.

We can quote for hoists or winches to almost any specification. The more popular chain hoists we offer can be viewed online under their own category of hand chain hoists. If you have a specific requirment for a winch or chain hoist please speak to one of our sales team and we can tailor your quotation to suit - for example we can offer spark resistant and corrosion resistant units, suitable for use in hazardous environments. The products of Selby Engineering and Lifting Safety are first choice for specifiers and engineers worldwide. Our davit sockets are used extensively in the chemical, water treatment and offshore oil and gas industries. We have a wealth of experience in the development of all types of individual davits and sockets for numerous applications.We offer several socket options for our davit arms, please see the drawings below.

Davit Sockets

Bolt-Down Surface Mount Socket

Available in 1000kg and 500kg ratings for use on flat surfaces. Cover plate can be supplied if required. Surface protection hot dip galvanised to BS1461 as standard. Stainless steel 304/316 material can be supplied/manufactured.

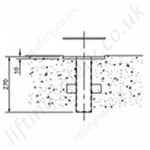

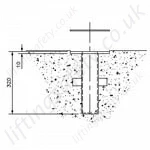

Grout-In Socket (with Cover Plate)

This type of socket is fitted when a flush non-trip hazard installation is required. A cover plate is fitted as standard, secured with 3 x 8mm fasteners. Surface protection hot dip galvanised to BS1461 as standard. Stainless Steel 304/316 can be supplied/manufactured.

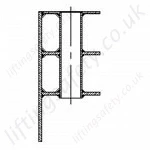

Wall-Type Sockets

Vertical installation to suit 500kg and 1000kg davits. Hot dip galvanised to BS1461. In our product range we offer back plates and tiebars to accompany the wall-type sockets for use on a brick wall. We also offer these items in stainless steel 304/316.

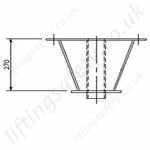

Inverted Davit Socket

Widely used in steel walkways where a flush installation is required to eliminate trip hazards.

This type of socket can be mounted flush within open mesh flooring section. Manufactured to suit the 500kg and 1000kg davit pins. Surface finish hot dip galvanised to BS1461 . This type of socket can be supplied in 304/316 stainless steel.

The drawings below give an indication of the style and size of davit's available, though as all our davit arm cranes are made to order the specification can be changed to meet your individual specification.

Thumbnail Image (please click to view full size image)

Thumbnail Image (please click to view full size image)

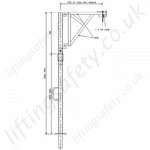

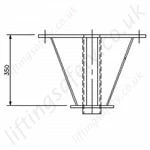

This image gives a dimensional drawing of the standard 500kg split pole lifting davit, which is suitable for use with a winch.

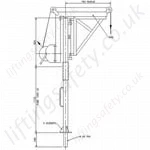

This image gives a dimensional drawing of the standard 1000kg split pole lifting davit.

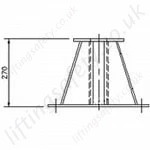

Dimensional drawing: 500kg SWL, surface mount lifting davit socket

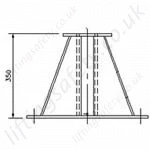

Dimensional drawing: 1000kg SWL, surface mount lifting davit socket

Dimensional drawing: 500kg SWL, wall mount lifting davit socket

Dimensional drawing: 1000kg SWL, wall mount lifting davit socket

Dimensional drawing: 500kg SWL, cast in lifting davit socket

Dimensional drawing: 1000kg SWL, cast in lifting davit socket

Dimensional drawing: 500kg SWL, inverted lifting davit socket

Dimensional drawing: 1000kg SWL, inverted lifting davit socket

Davit Cranes With Spark Resistant Features / Explosion proof.

SELS can include any anti-sparking features our customers specify on davit lifting arms we manufacture that are intended to be used in potentially explosive areas / atmospheres (Zone 1 & 2 etc...) – These features will enhance the davit’s anti-sparking properties and therefore make the crane more suitable for use in such potentially explosive environments.

SELS will not to take the responsibility of supplying our Davit cranes described as 'spark proof' or ‘Explosion Proof’ as this is ‘too broad’ a term. We believe that total compliance is probably impossible because of the mechanical operation and movement of a davit crane; i.e. we cannot offer a 100% guarantee that no part of the assembly is capable of generating a spark capable of igniting a flame. We supply / manufacture our cranes with anti sparking features according to the requirements and specification of our customers and therefore we ask our customers to provide a detailed specification and not just ask for sparkproof or explosion proof . Our cranes have been successfully supplied to customers in the offshore Oil and Gas industry in the UK on this basis.

Pricing

We offer several designs of lightweight portable davit lifting arms, including lean over type davits and vertical split pole type davits. The split pole davits are suited to applications where there is an obstruction which must be worked around, because the unit is relatively compact, it offers an excellent solution for a confined space or restricted access lifitng environments.

To help comply with the manual handling regulations our davit arms are made in three sections, this ensures that the davits are easily transportable when the davit is to be used in more than one location. They are supplied CE marked and come with a certificate of conformity. The design of the davits means that they are very portable. Many of our customers purchase several davit sockets, and permanently install these wherever they require the davit. One davit arm can then be purchased and easily transported between jobs - reducing the overall cost.

This type of light weight davit lifting arm is mainly manufactured from galvanized mild steel though can also be manufactured from aluminum or stainless steel if required. The galvanized steel arms are suitable for use in marine and offshore environments, whether this be for a lifting application in the offshore oil and gas industry, or for use on a boat. The aluminium option offers an even more lightweight solution. The Stainless Steel davit arms can be used in hazardous environments. These davits are often utilised in the petrochemical industry, where they are used in hazardous environments, and also the food industry, where regulations for cleanliness must be observed.

All of our special davit arm jib cranes can be manufactured to our customers specification (height of lift and reach). In order to maintain the integrity of the davit we recommend that for a Safe Working Load (SWL) of 500kg the radius (reach) does not exceed 1800mm; and for 1000kg 1200mm. The height to the lifting eye on the davit arm can be up to 3000mm. These figures are given as a rough guide. If your requirments do not fall within the advised parameters, please submit your required measurments, and we will quote the item or our suggested alternative that may meet your needs. If the reach of the davit arm you require exceeds our recomendations, but a lower safe working load is acceptable, then we could manufacture a bespoke davit arm that meets your requirments.

Our davit jib arms can be designed for the lifting of materials and / or for the lifting of people (manriding application). To view detailed specifications, information and options on our man-riding davits please click here. For general lifting applications the davit arm’s can be supplied up to 1000kg safe working load (SWL). For material lifting applications our Davits can be supplied with a manual hand winch, electric chain hoist, pneumatic hoists or hand chain block to suit your lifting needs and environment.

We can quote for hoists or winches to almost any specification. The more popular chain hoists we offer can be viewed online under their own category of hand chain hoists. If you have a specific requirment for a winch or chain hoist please speak to one of our sales team and we can tailor your quotation to suit - for example we can offer spark resistant and corrosion resistant units, suitable for use in hazardous environments. The products of Selby Engineering and Lifting Safety are first choice for specifiers and engineers worldwide. Our davit sockets are used extensively in the chemical, water treatment and offshore oil and gas industries. We have a wealth of experience in the development of all types of individual davits and sockets for numerous applications.We offer several socket options for our davit arms, please see the drawings below.

Davit Sockets

Bolt-Down Surface Mount Socket

Available in 1000kg and 500kg ratings for use on flat surfaces. Cover plate can be supplied if required. Surface protection hot dip galvanised to BS1461 as standard. Stainless steel 304/316 material can be supplied/manufactured.

Grout-In Socket (with Cover Plate)

This type of socket is fitted when a flush non-trip hazard installation is required. A cover plate is fitted as standard, secured with 3 x 8mm fasteners. Surface protection hot dip galvanised to BS1461 as standard. Stainless Steel 304/316 can be supplied/manufactured.

Wall-Type Sockets

Vertical installation to suit 500kg and 1000kg davits. Hot dip galvanised to BS1461. In our product range we offer back plates and tiebars to accompany the wall-type sockets for use on a brick wall. We also offer these items in stainless steel 304/316.

Inverted Davit Socket

Widely used in steel walkways where a flush installation is required to eliminate trip hazards.

This type of socket can be mounted flush within open mesh flooring section. Manufactured to suit the 500kg and 1000kg davit pins. Surface finish hot dip galvanised to BS1461 . This type of socket can be supplied in 304/316 stainless steel.

The drawings below give an indication of the style and size of davit's available, though as all our davit arm cranes are made to order the specification can be changed to meet your individual specification.

Thumbnail Image (please click to view full size image)

Thumbnail Image (please click to view full size image)

This image gives a dimensional drawing of the standard 500kg split pole lifting davit, which is suitable for use with a winch.

This image gives a dimensional drawing of the standard 1000kg split pole lifting davit.

Dimensional drawing: 500kg SWL, surface mount lifting davit socket

Dimensional drawing: 1000kg SWL, surface mount lifting davit socket

Dimensional drawing: 500kg SWL, wall mount lifting davit socket

Dimensional drawing: 1000kg SWL, wall mount lifting davit socket

Dimensional drawing: 500kg SWL, cast in lifting davit socket

Dimensional drawing: 1000kg SWL, cast in lifting davit socket

Dimensional drawing: 500kg SWL, inverted lifting davit socket

Dimensional drawing: 1000kg SWL, inverted lifting davit socket

Davit Cranes With Spark Resistant Features / Explosion proof.

SELS can include any anti-sparking features our customers specify on davit lifting arms we manufacture that are intended to be used in potentially explosive areas / atmospheres (Zone 1 & 2 etc...) – These features will enhance the davit’s anti-sparking properties and therefore make the crane more suitable for use in such potentially explosive environments.

SELS will not to take the responsibility of supplying our Davit cranes described as 'spark proof' or ‘Explosion Proof’ as this is ‘too broad’ a term. We believe that total compliance is probably impossible because of the mechanical operation and movement of a davit crane; i.e. we cannot offer a 100% guarantee that no part of the assembly is capable of generating a spark capable of igniting a flame. We supply / manufacture our cranes with anti sparking features according to the requirements and specification of our customers and therefore we ask our customers to provide a detailed specification and not just ask for sparkproof or explosion proof . Our cranes have been successfully supplied to customers in the offshore Oil and Gas industry in the UK on this basis.

You May Also Like

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.