-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Soft Lifting Slings

- Lifting Chain Slings

- Wire Rope Slings & Assemblies

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Beam Trolleys and Crane Bridges, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

-

Confined Space and Rescue Systems

- Xtirpa Confined Space Davit Arm Systems and Components

- Sala Advanced Davit Arm Systems and Components

- Genesi Confined Space Systems

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding Hoists & Rescue Winches

- Fall Arrest & Rescue Tripods

- Fall Arrest Davit Arms & Posts for Working at Height

-

Fall Arrest & Man-riding Systems

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

- Home/

- Lifting Equipment/

- Chain Hoists; Manual, Electric, Air/

- Electric Chain Hoists/

- Stahl Electric Chain Hoists/

- Stahl ST Electric Chain Hoist

Stahl ST Electric Chain Hoist

400v 3ph 50hz electric hoists with a wide variety of options such as extra low headroom and atex certification, in capacities from 125kg up to 5 tonne.

Stahl ST / SSEH-4522

Facts About Stahl ST Electric Hoist Line

The ST chain hoist programme ranks among the world’s most distinctive and extensive ranges on offer. Users, crane manufacturers and systems manufacturers appreciate the robust classic which proves itself in operation day for day. It is powerful, reliable and undemanding as regards maintenance and power consumption. The supervised series production of the standard components brings you economic advantages. And in conjunction with the precise manufacture of off-standard components, the ST chain hoist is an acknowledged top-level quality product.

The modular system permits numerous combinations of sub-assemblies to achieve your individual solutions.

The ST series from STAHL CraneSystems is available in 9 load capacity variants for the load capacity range from 125kg to 5-tonne.

ST chain hoists can be used as stationary models with suspension hook or eye, with rigid suspension or with a push trolley. Or when completed by an electric trolley they are mounted on standard cranes, off-standard cranes or in systems manufacture. The technical highlight which makes the ST chain hoist one of the safest around is the direct suspension on the patented solid cast iron chain guide. The load is supported at the point where it engages.

Various off-standard designs are available for use in particular conditions. Two constructions optimise the effective hook height of all chain hoist models if required. The headroom of the short-headroom trolley and the extra short-headroom trolley is a reduced Standard ST chain hoist with electric trolley by 33 % and over 60 % respectively. For exceptional requirements, our experts in the engineering department will develop suitable customised solutions. Even in explosive atmospheres, you do not have to manage without the ST chain hoist. On request, nearly the entire chain hoist programme is available in explosion-protected design for Zone 1, Zone 21 and Zone 22. It’s no coincidence that Stahl is a market leader for explosion-protected lifting technology and crane components.

- The most comprehensive chain hoist programme for the load capacity range from 125kg to 5,000kg

- Patented suspension directly on the chain guide

- Equipped with two hoisting speeds as standard

- Extremely short and compact construction ensures that space can be utilised to the maximum

- High standard classification in accordance with FEM

- Modern Kanban production, available fast

- Available as an option in explosion-protected design complying with ATEX and IECEx

Models and Suspension Options

Different construction types and trolley variants for the ST chain hoist open up the most varied applications in crane and systems manufacture. Individually tailored to your specific requirements as stationary hoist or for use with a trolley. The trolleys are equipped as standard with one travel speed, as an option the motors can be supplied with two travel speeds. But in this matter too we are open to your requirements. Our chain hoists are known worldwide for their flexible and versatile use. Compact dimensions and extremely short approach dimensions help to make optimum use of the production shop.

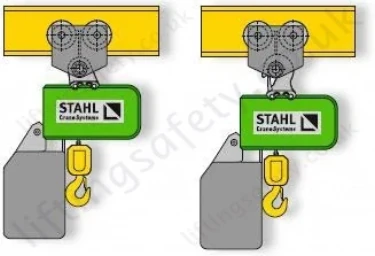

Stationary Suspension Options

The standard stationary ST chain hoist has hook suspension. However, you can also choose eye suspension or rigid suspension.

The eye suspension is used when the stationary chain hoist is only rarely moved to a different location, while the low headroom permits long hook paths even in low-ceilinged rooms. If the ST chain hoist is to be permanently mounted, for example in systems manufacture, we recommend rigid suspension. Here too the extremely short headroom is of advantage. In addition, the rigid mounting prevents the chain hoist from swinging on the trolley.

Hook Suspension

Eye Suspension

Rigid Suspension

Stationary Foot Mounting

In order to utilise space optimally in low-ceilinged rooms the ST chain hoist can be bolted from below onto a foot mounting.

ST05 Foot Mounting

ST10 - ST60 Foot Mounting - (View from Below)

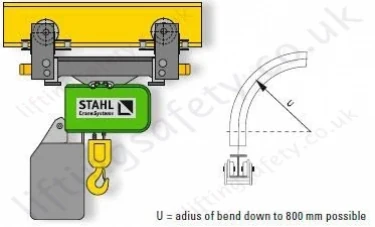

Trolley Options

|

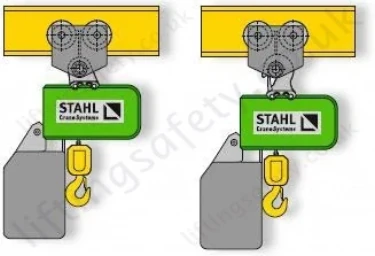

| Push Trolley In the standard version, the ST05 and ST 10 1/1 chain hoists are suspended by eye or hook from the smooth-running push trolleys. Rigid suspension of the chain hoist is possible on request. The push trolley does not affect the low headroom of the hoist. Optional wheel arresters make your workplace safer. |

|

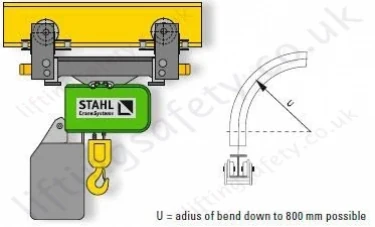

| DUE Articulating Trolley The DUE articulated trolley is available for frequent travel around bends and narrow radii. Depending on the radius of the bend, runway flange width or application it is equipped with one or two travel motors. The lateral guide rollers cause minimum wear. The DUE articulated trolley is designed for load capacities up to 6,300kg. |

|

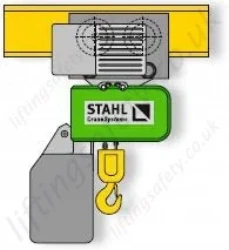

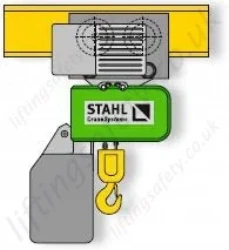

| Standard Headroom Electric Trolley Even with the smooth-running electric trolley, the extremely short headroom permitting long hook paths is typical. |

|

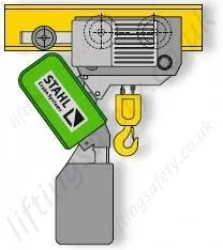

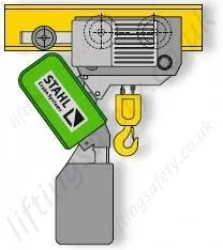

| Short Headroom Electric Trolley The smooth-running electric trolley can also be combined with the ST short headroom chain hoist, reducing the headroom by a further 33%. |

Hoist Specifications

| Capacity (kg) | FEM Rating (ISO) | Lifting Speed (m/min) | Model/Type | Number of falls |

Motor Data | ||

| kW | Duty Cycle (%ED) | Operations/Hour (c/h) | |||||

| 125 | 3m (M6) | 8/2 | ST 0501-8/2 | 1/1 | 0.2/0.05 | 35/15 | 240/480 |

| 250 | 1Am (M4) | 8/2 | ST 0502-8/2 | 1/1 | 0.4/0.1 | 35/15 | 120/240 |

| 500 | 1Am (M4) | 4/1 | ST 0502-8/2 | 2/1 | 0.4/0.1 | 35/15 | 120/240 |

| 500 | 1Am (M4) | 8/2 | ST 1005-8/2 | 1/1 | 0.8/0.2 | 40/20 | 120/240 |

| 500 | 1Am (M4) | 12/3 | ST 1005-12/3 | 1/1 | 1.2/0.3 | 40/20 | 120/240 |

| 1000 | 1Am (M4) | 4/1 | ST 1005-8/2 | 2/1 | 0.8/0.2 | 40/20 | 120/240 |

| 1000 | 1Am (M4) | 6/1.5 | ST 1005-12/3 | 2/1 | 1.2/0.3 | 40/20 | 120/240 |

| 1000 | 1Am (M4) | 8/2 | ST 2010-8/2 | 1/1 | 1.5/0.37 | 40/20 | 120/240 |

| 1000 | 1Am (M4) | 12/3 | ST 2010-12/ | 1/1 | 12/3 | 40/20 | 120/240 |

| 1600 | 1Bm (M3) | 8/2 | ST 3016-8/2 | 1/1 | 2.3/0.57 | 40/20 | 120/240 |

| 1600 | 2m (M5) | 8/2 | ST 3216-8/2 | 1/1 | 2.4/0.6 | 40/20 | 120/240 |

| 2000 | 1Am (M4) | 4/1 | ST 2010-8/2 | 2/1 | 1.5/0.37 | 40/20 | 120/240 |

| 2500 | 1Am (M4) | 6.3/1.5 | ST 5025-6/1 | 1/1 | 3.0/0.76 | 40/20 | 120/240 |

| 2500 | 1Am (M4) | 8/2 | ST 5025-8/2 | 1/1 | 3.8/0.9 | 33/17 | 100/200 |

| 3200 | 1Bm (M3) | 4/1 | ST 3016-8/2 | 2/1 | 2.3/0.57 | 40/20 | 120/240 |

| 3200 | 2m (M5) | 4/1 | ST 3216-8/2 | 2/1 | 2.4/0.6 | 40/20 | 120/240 |

| 5000 | 1Am (M4) | 3.2/0.75 | ST 5025-6/1 | 2/1 | 3.0/0.76 | 40/20 | 120/240 |

| 5000 | 1Am (M4) | 4/1 | ST 5025-8/2 | 2/1 | 3.8/0.9 | 33/17 | 100/200 |

Explanation of Duty Cycle

%ED is how long the motor can run in a 10 minute period

40% ED means the motor can run for 4 minutes and then needs to rest for 6

20% ED means the motor can run for 2 minutes and then needs to rest for 8

Pricing

Availability

Please note that this may be subject to change, particularly on larger capacity units. For urgent orders, please contact our sales team that will gladly assist.

Facts About Stahl ST Electric Hoist Line

The ST chain hoist programme ranks among the world’s most distinctive and extensive ranges on offer. Users, crane manufacturers and systems manufacturers appreciate the robust classic which proves itself in operation day for day. It is powerful, reliable and undemanding as regards maintenance and power consumption. The supervised series production of the standard components brings you economic advantages. And in conjunction with the precise manufacture of off-standard components, the ST chain hoist is an acknowledged top-level quality product.

The modular system permits numerous combinations of sub-assemblies to achieve your individual solutions.

The ST series from STAHL CraneSystems is available in 9 load capacity variants for the load capacity range from 125kg to 5-tonne.

ST chain hoists can be used as stationary models with suspension hook or eye, with rigid suspension or with a push trolley. Or when completed by an electric trolley they are mounted on standard cranes, off-standard cranes or in systems manufacture. The technical highlight which makes the ST chain hoist one of the safest around is the direct suspension on the patented solid cast iron chain guide. The load is supported at the point where it engages.

Various off-standard designs are available for use in particular conditions. Two constructions optimise the effective hook height of all chain hoist models if required. The headroom of the short-headroom trolley and the extra short-headroom trolley is a reduced Standard ST chain hoist with electric trolley by 33 % and over 60 % respectively. For exceptional requirements, our experts in the engineering department will develop suitable customised solutions. Even in explosive atmospheres, you do not have to manage without the ST chain hoist. On request, nearly the entire chain hoist programme is available in explosion-protected design for Zone 1, Zone 21 and Zone 22. It’s no coincidence that Stahl is a market leader for explosion-protected lifting technology and crane components.

- The most comprehensive chain hoist programme for the load capacity range from 125kg to 5,000kg

- Patented suspension directly on the chain guide

- Equipped with two hoisting speeds as standard

- Extremely short and compact construction ensures that space can be utilised to the maximum

- High standard classification in accordance with FEM

- Modern Kanban production, available fast

- Available as an option in explosion-protected design complying with ATEX and IECEx

Models and Suspension Options

Different construction types and trolley variants for the ST chain hoist open up the most varied applications in crane and systems manufacture. Individually tailored to your specific requirements as stationary hoist or for use with a trolley. The trolleys are equipped as standard with one travel speed, as an option the motors can be supplied with two travel speeds. But in this matter too we are open to your requirements. Our chain hoists are known worldwide for their flexible and versatile use. Compact dimensions and extremely short approach dimensions help to make optimum use of the production shop.

Stationary Suspension Options

The standard stationary ST chain hoist has hook suspension. However, you can also choose eye suspension or rigid suspension.

The eye suspension is used when the stationary chain hoist is only rarely moved to a different location, while the low headroom permits long hook paths even in low-ceilinged rooms. If the ST chain hoist is to be permanently mounted, for example in systems manufacture, we recommend rigid suspension. Here too the extremely short headroom is of advantage. In addition, the rigid mounting prevents the chain hoist from swinging on the trolley.

Hook Suspension

Eye Suspension

Rigid Suspension

Stationary Foot Mounting

In order to utilise space optimally in low-ceilinged rooms the ST chain hoist can be bolted from below onto a foot mounting.

ST05 Foot Mounting

ST10 - ST60 Foot Mounting - (View from Below)

Trolley Options

|

| Push Trolley In the standard version, the ST05 and ST 10 1/1 chain hoists are suspended by eye or hook from the smooth-running push trolleys. Rigid suspension of the chain hoist is possible on request. The push trolley does not affect the low headroom of the hoist. Optional wheel arresters make your workplace safer. |

|

| DUE Articulating Trolley The DUE articulated trolley is available for frequent travel around bends and narrow radii. Depending on the radius of the bend, runway flange width or application it is equipped with one or two travel motors. The lateral guide rollers cause minimum wear. The DUE articulated trolley is designed for load capacities up to 6,300kg. |

|

| Standard Headroom Electric Trolley Even with the smooth-running electric trolley, the extremely short headroom permitting long hook paths is typical. |

|

| Short Headroom Electric Trolley The smooth-running electric trolley can also be combined with the ST short headroom chain hoist, reducing the headroom by a further 33%. |

Hoist Specifications

| Capacity (kg) | FEM Rating (ISO) | Lifting Speed (m/min) | Model/Type | Number of falls |

Motor Data | ||

| kW | Duty Cycle (%ED) | Operations/Hour (c/h) | |||||

| 125 | 3m (M6) | 8/2 | ST 0501-8/2 | 1/1 | 0.2/0.05 | 35/15 | 240/480 |

| 250 | 1Am (M4) | 8/2 | ST 0502-8/2 | 1/1 | 0.4/0.1 | 35/15 | 120/240 |

| 500 | 1Am (M4) | 4/1 | ST 0502-8/2 | 2/1 | 0.4/0.1 | 35/15 | 120/240 |

| 500 | 1Am (M4) | 8/2 | ST 1005-8/2 | 1/1 | 0.8/0.2 | 40/20 | 120/240 |

| 500 | 1Am (M4) | 12/3 | ST 1005-12/3 | 1/1 | 1.2/0.3 | 40/20 | 120/240 |

| 1000 | 1Am (M4) | 4/1 | ST 1005-8/2 | 2/1 | 0.8/0.2 | 40/20 | 120/240 |

| 1000 | 1Am (M4) | 6/1.5 | ST 1005-12/3 | 2/1 | 1.2/0.3 | 40/20 | 120/240 |

| 1000 | 1Am (M4) | 8/2 | ST 2010-8/2 | 1/1 | 1.5/0.37 | 40/20 | 120/240 |

| 1000 | 1Am (M4) | 12/3 | ST 2010-12/ | 1/1 | 12/3 | 40/20 | 120/240 |

| 1600 | 1Bm (M3) | 8/2 | ST 3016-8/2 | 1/1 | 2.3/0.57 | 40/20 | 120/240 |

| 1600 | 2m (M5) | 8/2 | ST 3216-8/2 | 1/1 | 2.4/0.6 | 40/20 | 120/240 |

| 2000 | 1Am (M4) | 4/1 | ST 2010-8/2 | 2/1 | 1.5/0.37 | 40/20 | 120/240 |

| 2500 | 1Am (M4) | 6.3/1.5 | ST 5025-6/1 | 1/1 | 3.0/0.76 | 40/20 | 120/240 |

| 2500 | 1Am (M4) | 8/2 | ST 5025-8/2 | 1/1 | 3.8/0.9 | 33/17 | 100/200 |

| 3200 | 1Bm (M3) | 4/1 | ST 3016-8/2 | 2/1 | 2.3/0.57 | 40/20 | 120/240 |

| 3200 | 2m (M5) | 4/1 | ST 3216-8/2 | 2/1 | 2.4/0.6 | 40/20 | 120/240 |

| 5000 | 1Am (M4) | 3.2/0.75 | ST 5025-6/1 | 2/1 | 3.0/0.76 | 40/20 | 120/240 |

| 5000 | 1Am (M4) | 4/1 | ST 5025-8/2 | 2/1 | 3.8/0.9 | 33/17 | 100/200 |

Explanation of Duty Cycle

%ED is how long the motor can run in a 10 minute period

40% ED means the motor can run for 4 minutes and then needs to rest for 6

20% ED means the motor can run for 2 minutes and then needs to rest for 8

You May Also Like

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.