-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Lifting Slings and Components

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Runway Beam Monorail Crane Trolleys, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms and Jib Cranes

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

- Man-riding Hoists & Rescue Winches

-

Fall Arrest & Man-riding Systems

- Fall Arrest Davit Arms & Posts for Working at Height

- Sala Advanced Davit Arm Systems and Components

- Xtirpa Confined Space Davit Arm Systems and Components

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding & Rescue Tripods & Quadpods

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

- Home/

- Lifting Equipment/

- Chain Hoists; Manual, Electric, Air/

- Hand Chain Blocks/

- Hook Suspended Chain Blocks/

- Tiger Hook Suspended Chain Hoists (Block and Tackle)/

- Tiger "ProCB14" Manual Chain Block

Tiger "ProCB14" Manual Chain Block

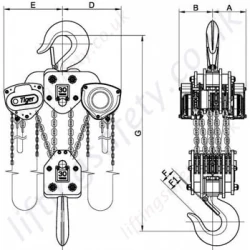

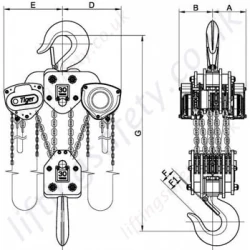

Hook suspension manual chain hoist that can be safely used for “fleeting” and “cross-hauling” applications up to 45°. Available with optional top and bottom 'adaptor' fittings. 250kg to 35t.

PROCB / TMCH-5185

The Tiger 'PROCB14' is the new name for the 'TCB14' Tiger hand chain hoist but with all the same characteristics; manufactured from the highest quality steel materials, offering a lightweight, compact and rugged construction, producing an exceptionally strong product resistant to impact damage.

The exceptional short head room allows for easy installation where every centimetre must be achieved.

Using only the highest quality materials precisely machined in Tigers own factory, the TCB is the ideal chain block for long term use with less maintenance and servicing costs.

These hoists meet and exceed all the requirements within BS EN 13157: 2004+A1:2009, ANSI/ASME B30.16, AS1418.2 and SANS 1594.

Certification

Each hoist comes fully certified with a test certificate or an EC Declaration of Conformity stating compliance with the essential health and safety requirements of the Machinery Directive 2006/42/EC. This document clearly states that the chain block has been proof tested at 1.5 times the rated capacity and the light load test of 2% of the rated capacity, which exceeds the requirements of the current applicable standard.

Main Features

- Range from 500kg – 35000kg.

- DNV GL Verification tested according to NORSOK R-002.

- Rugged steel body construction.

- Drop forged & heat treated alloy hooks.

- Certified 2% light load protection.

- Proof tested to 1.5 times rated capacity.

- Suitable for underground mining use.

- Available with stainless steel load chain.

- Available with forged clevis adaptor components in place of the standard upper and lower hook blocks.

- Lightweight and portable.

- High quality alloy calibrated load chain.

- Heat treated alloy steel triple spur gears and pinion shaft.

- Can be chained to meet your exact requirements.

- Tested and certified for “fleeting” and “cross-hauling” applications up to 45°.

- Meets or exceeds all international standards.

- 8t, 15t and 30t capacity units available.

- Double cover protection for brake chamber.

- Patented Quad Cam pawl system.

- Operating temperature of -40°C to +50°C.

- Individual spares readily available.

- Overload protection available.

- Meets and exceeds all international standards.

- Can be supplied with Various Top and Bottom fitting to suit your needs, see the 'Adaptor Fittings' tab above for further information.

Safety Brake:

The highly efficient and fully corrosion protected brake systems works instantly when the operation is stopped and securely holds the load. Loads are lowered under perfect control, allowing for precise operations. The TCB passes easily the “brake lock out test” as per BS 3243 with a 2% load of the rated capacity.

Double Cover Protection:

Both the hand chain wheel cover and the ratchet brake cover are designed to offer protection to the brake chamber in the harshest environments from foreign objects.

Lifting at Angles

The TCB range of chain blocks fitted with the patented protected quad cam brake system has undergone a full and comprehensive testing regime that was drawn up by industry specialists and Tiger’s mechanical engineers to provide evidence that these units can be safely used for “fleeting” and “cross-hauling” applications up to 45°. Note: All such operations should be carried out in accordance with manufacturer’s instructions and fully risk assessed by a competent person.

Load Chains:

Tiger only use the highest quality alloy, calibrated load chains in Grade 80 (T) or 100 (V) conforming to EN818-7 and ISO 16872. Also available with stainless steel load chain.

Overload Protection:

If the chain hoist is fitted with a slipping clutch overload mechanism then it is protected from overload. When the load limit is exceeded, the clutch in the chain wheel will slip, allowing the hand wheel to be rotated whilst not engaging the gear box. The prevents further lifting of the load, though lowering is still possible.

Grease:

High performance premium quality grease allows the TCB Blocks to be certified for use within a temperature range of -40°C to +50°C, far exceeding the requirements of current standards.

Chain end stops:

Will hold a load of at least 2.5 times the rated capacity when supporting the full load without restraint from other components e.g. brake or gearing. This prevents accidents, by acting as a stop when the lift length of the load chain is exceeded when lowered.

Mechanical Efficiency:

All major components are heat treated and precisely machined to ensure long term smooth operation. High gear ratios keep physical effort to a minimum.

Convertibility

The TCB can be easily converted to have Load Limiters fitted. The top hook can be replaced by a competent person so the TCB can be directly fitted to our beam trolley range of the equivalent capacity achieving the lowest possible headroom.

Hoist Performance:

The TCB has undergone a full test program that includes:

Type Testing

- Ultimate strength test, at least 4 times the Working Load Limit (WLL)

- Continuous cyclic testing of over 1500 cycles

- Chain end anchorage test, passing at least 2.5 times the WLL without any restriction of the brake or gears

Test on every hoist

- Proof loading at 1.5 times the rated capacity

- Light load testing at maximum of 2% rated capacity

Quad Cam Brake Pawl System

Specifically designed so there is always a permanent engagement of one of the reciprocal pawls in the ratchet wheel. Most importantly, in the unlikely event of a pawl spring failure, this new design ensures the brake is alwys fully functional and the load is sustained without damage to the mechanism. With a conventional twin pawl brake mechanism (tear drop) failure can occur if the pawl spring erodes, fractures or a shock load bounces the pawls out of the ratchet gear. Without the spring these systems reply on gravity keeping the pawls enegaged and are flawed when the hoist is used at angles away from the vertical.

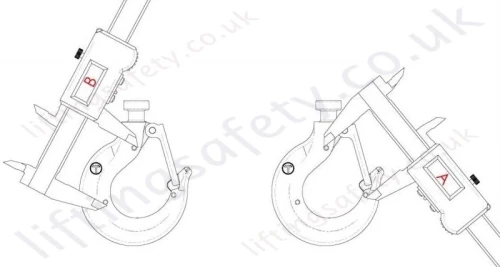

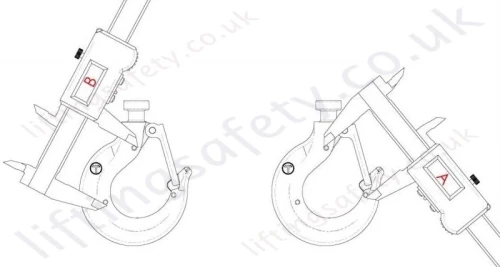

Hooks / Hook Blocks

The hooks incorporated the Patent Pending "EZ Check" feature, which allows operator and inspection engineers to easily check if the hook is streteched from overloading or shock loading etc. by simply measuring measuring between the triangle of pop marks (see the Hook Spec. tab above). Drop forged and heat treated alloy hooks are furnished with heavy duty latch kits that fully engage into the nose of the hook offering maximum load security. The swivel hooks are attached to the yoke using high grade nuts & bolts allowing for complete inspection during any statutory inspection or written scheme maintenance. The entire hook fitting has been protected using OCP or stainless steel fixtures and fittings. Recessed forgings offer full protection to the load chain anchor bolts on all Tiger bottom hooks.

Finish

The TCB is finished in our high quality powder coat paint offering excellent corrosion protection.

Brake Efficiency

Tiger uniquely uses an 8 point multi start thread pinion shaft whicj has measurably increased the efficiency in the brake reaction times.

Hand Wheel

For chain blocks to be used up to an angle of 45°, it's critical that the chand chain leavesand enters the hand wheel without twisting, snagging or jamming. Thanks to the specially designed deep-profile chain block hand wheel this is achievable as it helps to seat the chain no matter what angle or direction of pull.

Dimensions and Specifications

| Capacity | Part Number (@3m HOL) | Effort (kg) | Dimensions (mm) | Load Chain | Standard HOL (m) | Mass (kg) @ std HOL | Mass (kg) per extra metre HOL | ||||||

| A | B | D | E | F1 | G | Diameter (mm) | No. of falls | ||||||

| 0.25 | CB-0025-03 | To be confirmed | |||||||||||

| 0.5 | CB-0050-03 | 21 | 93 | 66 | 52 | 78 | 24 | 305 | 6.3 | 1 | 3 | 10.8 | 1.86 |

| 1.0 | CB-0100-03 | 25 | 93 | 66 | 63 | 87 | 28 | 340 | 6.3 | 1 | 3 | 11.8 | 1.86 |

| 1.5 | CB-0150-03 | 32 | 98 | 73 | 78 | 102 | 34 | 385 | 7.1 | 1 | 3 | 16.2 | 2.10 |

| 2.0 | CB-0200-03 | 34 | 101 | 79 | 87 | 113 | 35 | 420 | 8.0 | 1 | 3 | 20.0 | 2.39 |

| 2.0 Lite | CB-0200L-03 | 42 | 98 | 73 | 78 | 103 | 35 | 399 | 7.1 | 1 | 3 | 16.7 | 2.10 |

| 3.0 1-Fall | CB-0300-03 | 38 | 109 | 84 | 98 | 157 | 36 | 550 | 10.0 | 1 | 3 | 30.6 | 3.17 |

| 3.0 2-Fall | CB-030T-03 | 34 | 98 | 73 | 60 | 148 | 36 | 465 | 7.1 | 2 | 3 | 23.3 | 3.20 |

| 5.0 | CB-0500-03 | 37 | 101 | 79 | 122 | 209 | 49 | 575 | 8.0 | 3 | 3 | 37.8 | 5.17 |

| 8.0 | CB-0800-03 | 37 | 101 | 79 | 140 | 238 | 51 | 745 | 8.0 | 4 | 3 | 64.0 | 6.56 |

| 10.0 | CB-1000-03 | 40 | 109 | 84 | 153 | 263 | 54 | 660 | 10.0 | 3 | 3 | 64.0 | 7.54 |

| 15.0 | CB-1500-03 | 41 | 110 | 84 | 225 | 378 | 59 | 840 | 10.0 | 5 | 3 | 128.5 | 11.85 |

| 20.0 | CB-2000-03 | 43 | 161 | 90 | 148 | 360 | 81 | 1050 | 10.0 | 6 | 3 | 178.7 | 14.20 |

| 20.0 Twin Head | CB-200T-03 | 43 | 161 | 161 | 383 | 383 | 81 | 1050 | 10.0 | 6 | 3 | 210.4 | 15.20 |

| 30.0 | CB-3000-03 | 42 | 220 | 220 | 388 | 388 | 91 | 1200 | 10.0 | 10 | 3 | 306.9 | 23.80 |

| 35.0 | CB-3500-03 | To be confirmed | |||||||||||

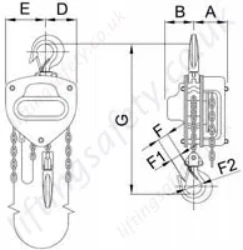

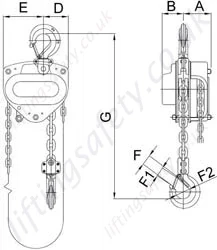

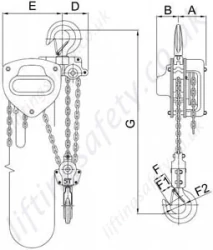

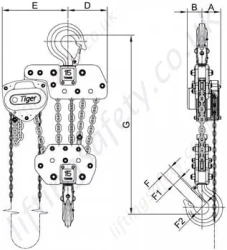

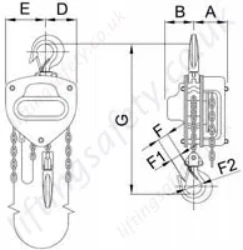

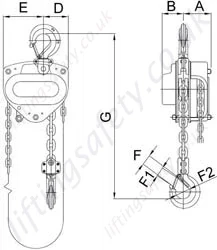

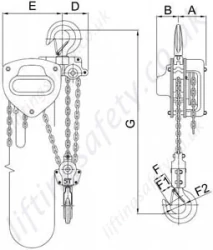

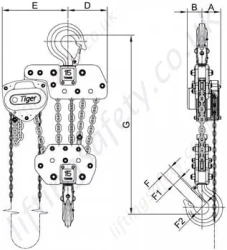

Dimensional Drawings

|

|

|

|

| 0.5 tonne to 2.0 tonne | 3.0 tonne twin fall | 3.0 tonne single fall | 5.0 tonne |

|

|

|

|

| 8.0 tonne | 10 tonne | 15 tonne | 20 tonne single head |

|

|

| 20 tonne twin head | 30 tonne |

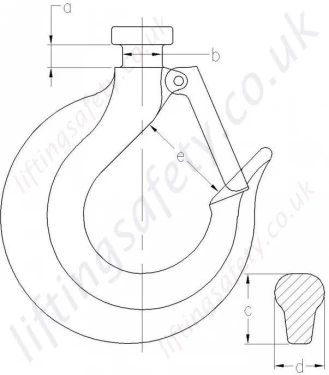

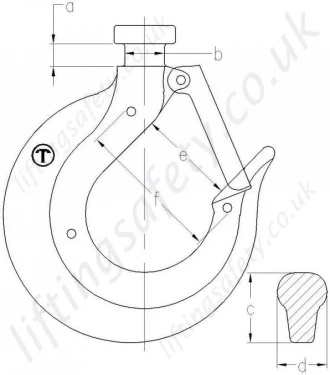

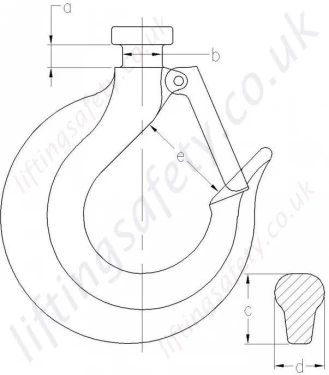

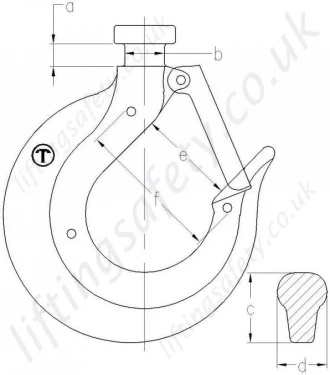

Hook Specifications

| Capacity (tonnes) | Collar Measurements (mm) | Hook Thickness at point shown in diagram (mm) | Hook throat Opening (mm) | "Ez Check" Measurement (mm) | ||

| a | c | c | d | e | f | |

| 0.5 | 8 | 13.5 | 19 | 15 | 29 | 45 |

| 1.0 | 8 | 13.5 | 23 | 17 | 33 | 52 |

| 1.5 | 10 | 15.5 | 26 | 21 | 38 | 59 |

| 2.0 | 10 | 17.5 | 30 | 22 | 42 | 64 |

| 3.0 | 12.5 | 20 | 37 | 32 | 40 | 76 |

| 5.0 | 19 | 30 | 43 | 36 | 54 | 86 |

| 8.0 | 21.7 | 33 | 50 | 43 | 55 | 110 |

| 10.0 | 20 | 33 | 52 | 48 | 60 | 121 |

| 15.0 | - | 36 | 67 | 60 | 64 | 130 |

| 20.0 | - | 48 | 77 | 72 | 90 | 162 |

| 30.0 | - | 56 | 94 | 78 | 100 | 177 |

Traditional Tiger Hooks

Tiger Hooks with new "EZ Check" 3 point marking system

Newer models of the TCB are fitted with the patent pending Tiger “EZ check” 3 point marking system. With this system a quick check that the A and B measurements are the same (as shown in the diagram below) will indicate if the hooks have stretched If A≦B the hook is fine; If A>B the hook needs to be replaced:

Tiger Adaptor Hoists are available with a drop-forged clevis adaptor allowing for the interchangeable range of EN1677 Tiger grade 100 clevis fittings.

This Tiger manufactured knuckle configuration gives 360° Rotation and 180° Pivot for maximum flexibility, whilst maintaining our 4:1 factor of safety at all angles.

- Available for Tiger TCB14 / SS12 chain blocks and PROLH / SS11 / TLH lever hoists.

- All fittings meet the standards of EN1677 grade 100 at 400°C tempering.

- Drop forged adaptor for maximum strength certified 4:1 FOS at all angles.

- Self-locking (safety) hook, clevis shackle, reevable egg (master) link or sling hook fitting available.

- Overload protection available.

- For lifting at angles (cross hauling/fleeting/drifting) with no deration.

- Chain Blocks – 500kg – 10t capacity.

- Lever Hoists – 800kg – 10t capacity.

Adaptor Sling Hook

Safety Hooks

Reevable Egg Link

Hoist Clevis Shackle

Adaptor Rotation

Pricing

The Tiger 'PROCB14' is the new name for the 'TCB14' Tiger hand chain hoist but with all the same characteristics; manufactured from the highest quality steel materials, offering a lightweight, compact and rugged construction, producing an exceptionally strong product resistant to impact damage.

The exceptional short head room allows for easy installation where every centimetre must be achieved.

Using only the highest quality materials precisely machined in Tigers own factory, the TCB is the ideal chain block for long term use with less maintenance and servicing costs.

These hoists meet and exceed all the requirements within BS EN 13157: 2004+A1:2009, ANSI/ASME B30.16, AS1418.2 and SANS 1594.

Certification

Each hoist comes fully certified with a test certificate or an EC Declaration of Conformity stating compliance with the essential health and safety requirements of the Machinery Directive 2006/42/EC. This document clearly states that the chain block has been proof tested at 1.5 times the rated capacity and the light load test of 2% of the rated capacity, which exceeds the requirements of the current applicable standard.

Main Features

- Range from 500kg – 35000kg.

- DNV GL Verification tested according to NORSOK R-002.

- Rugged steel body construction.

- Drop forged & heat treated alloy hooks.

- Certified 2% light load protection.

- Proof tested to 1.5 times rated capacity.

- Suitable for underground mining use.

- Available with stainless steel load chain.

- Available with forged clevis adaptor components in place of the standard upper and lower hook blocks.

- Lightweight and portable.

- High quality alloy calibrated load chain.

- Heat treated alloy steel triple spur gears and pinion shaft.

- Can be chained to meet your exact requirements.

- Tested and certified for “fleeting” and “cross-hauling” applications up to 45°.

- Meets or exceeds all international standards.

- 8t, 15t and 30t capacity units available.

- Double cover protection for brake chamber.

- Patented Quad Cam pawl system.

- Operating temperature of -40°C to +50°C.

- Individual spares readily available.

- Overload protection available.

- Meets and exceeds all international standards.

- Can be supplied with Various Top and Bottom fitting to suit your needs, see the 'Adaptor Fittings' tab above for further information.

Safety Brake:

The highly efficient and fully corrosion protected brake systems works instantly when the operation is stopped and securely holds the load. Loads are lowered under perfect control, allowing for precise operations. The TCB passes easily the “brake lock out test” as per BS 3243 with a 2% load of the rated capacity.

Double Cover Protection:

Both the hand chain wheel cover and the ratchet brake cover are designed to offer protection to the brake chamber in the harshest environments from foreign objects.

Lifting at Angles

The TCB range of chain blocks fitted with the patented protected quad cam brake system has undergone a full and comprehensive testing regime that was drawn up by industry specialists and Tiger’s mechanical engineers to provide evidence that these units can be safely used for “fleeting” and “cross-hauling” applications up to 45°. Note: All such operations should be carried out in accordance with manufacturer’s instructions and fully risk assessed by a competent person.

Load Chains:

Tiger only use the highest quality alloy, calibrated load chains in Grade 80 (T) or 100 (V) conforming to EN818-7 and ISO 16872. Also available with stainless steel load chain.

Overload Protection:

If the chain hoist is fitted with a slipping clutch overload mechanism then it is protected from overload. When the load limit is exceeded, the clutch in the chain wheel will slip, allowing the hand wheel to be rotated whilst not engaging the gear box. The prevents further lifting of the load, though lowering is still possible.

Grease:

High performance premium quality grease allows the TCB Blocks to be certified for use within a temperature range of -40°C to +50°C, far exceeding the requirements of current standards.

Chain end stops:

Will hold a load of at least 2.5 times the rated capacity when supporting the full load without restraint from other components e.g. brake or gearing. This prevents accidents, by acting as a stop when the lift length of the load chain is exceeded when lowered.

Mechanical Efficiency:

All major components are heat treated and precisely machined to ensure long term smooth operation. High gear ratios keep physical effort to a minimum.

Convertibility

The TCB can be easily converted to have Load Limiters fitted. The top hook can be replaced by a competent person so the TCB can be directly fitted to our beam trolley range of the equivalent capacity achieving the lowest possible headroom.

Hoist Performance:

The TCB has undergone a full test program that includes:

Type Testing

- Ultimate strength test, at least 4 times the Working Load Limit (WLL)

- Continuous cyclic testing of over 1500 cycles

- Chain end anchorage test, passing at least 2.5 times the WLL without any restriction of the brake or gears

Test on every hoist

- Proof loading at 1.5 times the rated capacity

- Light load testing at maximum of 2% rated capacity

Quad Cam Brake Pawl System

Specifically designed so there is always a permanent engagement of one of the reciprocal pawls in the ratchet wheel. Most importantly, in the unlikely event of a pawl spring failure, this new design ensures the brake is alwys fully functional and the load is sustained without damage to the mechanism. With a conventional twin pawl brake mechanism (tear drop) failure can occur if the pawl spring erodes, fractures or a shock load bounces the pawls out of the ratchet gear. Without the spring these systems reply on gravity keeping the pawls enegaged and are flawed when the hoist is used at angles away from the vertical.

Hooks / Hook Blocks

The hooks incorporated the Patent Pending "EZ Check" feature, which allows operator and inspection engineers to easily check if the hook is streteched from overloading or shock loading etc. by simply measuring measuring between the triangle of pop marks (see the Hook Spec. tab above). Drop forged and heat treated alloy hooks are furnished with heavy duty latch kits that fully engage into the nose of the hook offering maximum load security. The swivel hooks are attached to the yoke using high grade nuts & bolts allowing for complete inspection during any statutory inspection or written scheme maintenance. The entire hook fitting has been protected using OCP or stainless steel fixtures and fittings. Recessed forgings offer full protection to the load chain anchor bolts on all Tiger bottom hooks.

Finish

The TCB is finished in our high quality powder coat paint offering excellent corrosion protection.

Brake Efficiency

Tiger uniquely uses an 8 point multi start thread pinion shaft whicj has measurably increased the efficiency in the brake reaction times.

Hand Wheel

For chain blocks to be used up to an angle of 45°, it's critical that the chand chain leavesand enters the hand wheel without twisting, snagging or jamming. Thanks to the specially designed deep-profile chain block hand wheel this is achievable as it helps to seat the chain no matter what angle or direction of pull.

Dimensions and Specifications

| Capacity | Part Number (@3m HOL) | Effort (kg) | Dimensions (mm) | Load Chain | Standard HOL (m) | Mass (kg) @ std HOL | Mass (kg) per extra metre HOL | ||||||

| A | B | D | E | F1 | G | Diameter (mm) | No. of falls | ||||||

| 0.25 | CB-0025-03 | To be confirmed | |||||||||||

| 0.5 | CB-0050-03 | 21 | 93 | 66 | 52 | 78 | 24 | 305 | 6.3 | 1 | 3 | 10.8 | 1.86 |

| 1.0 | CB-0100-03 | 25 | 93 | 66 | 63 | 87 | 28 | 340 | 6.3 | 1 | 3 | 11.8 | 1.86 |

| 1.5 | CB-0150-03 | 32 | 98 | 73 | 78 | 102 | 34 | 385 | 7.1 | 1 | 3 | 16.2 | 2.10 |

| 2.0 | CB-0200-03 | 34 | 101 | 79 | 87 | 113 | 35 | 420 | 8.0 | 1 | 3 | 20.0 | 2.39 |

| 2.0 Lite | CB-0200L-03 | 42 | 98 | 73 | 78 | 103 | 35 | 399 | 7.1 | 1 | 3 | 16.7 | 2.10 |

| 3.0 1-Fall | CB-0300-03 | 38 | 109 | 84 | 98 | 157 | 36 | 550 | 10.0 | 1 | 3 | 30.6 | 3.17 |

| 3.0 2-Fall | CB-030T-03 | 34 | 98 | 73 | 60 | 148 | 36 | 465 | 7.1 | 2 | 3 | 23.3 | 3.20 |

| 5.0 | CB-0500-03 | 37 | 101 | 79 | 122 | 209 | 49 | 575 | 8.0 | 3 | 3 | 37.8 | 5.17 |

| 8.0 | CB-0800-03 | 37 | 101 | 79 | 140 | 238 | 51 | 745 | 8.0 | 4 | 3 | 64.0 | 6.56 |

| 10.0 | CB-1000-03 | 40 | 109 | 84 | 153 | 263 | 54 | 660 | 10.0 | 3 | 3 | 64.0 | 7.54 |

| 15.0 | CB-1500-03 | 41 | 110 | 84 | 225 | 378 | 59 | 840 | 10.0 | 5 | 3 | 128.5 | 11.85 |

| 20.0 | CB-2000-03 | 43 | 161 | 90 | 148 | 360 | 81 | 1050 | 10.0 | 6 | 3 | 178.7 | 14.20 |

| 20.0 Twin Head | CB-200T-03 | 43 | 161 | 161 | 383 | 383 | 81 | 1050 | 10.0 | 6 | 3 | 210.4 | 15.20 |

| 30.0 | CB-3000-03 | 42 | 220 | 220 | 388 | 388 | 91 | 1200 | 10.0 | 10 | 3 | 306.9 | 23.80 |

| 35.0 | CB-3500-03 | To be confirmed | |||||||||||

Dimensional Drawings

|

|

|

|

| 0.5 tonne to 2.0 tonne | 3.0 tonne twin fall | 3.0 tonne single fall | 5.0 tonne |

|

|

|

|

| 8.0 tonne | 10 tonne | 15 tonne | 20 tonne single head |

|

|

| 20 tonne twin head | 30 tonne |

Hook Specifications

| Capacity (tonnes) | Collar Measurements (mm) | Hook Thickness at point shown in diagram (mm) | Hook throat Opening (mm) | "Ez Check" Measurement (mm) | ||

| a | c | c | d | e | f | |

| 0.5 | 8 | 13.5 | 19 | 15 | 29 | 45 |

| 1.0 | 8 | 13.5 | 23 | 17 | 33 | 52 |

| 1.5 | 10 | 15.5 | 26 | 21 | 38 | 59 |

| 2.0 | 10 | 17.5 | 30 | 22 | 42 | 64 |

| 3.0 | 12.5 | 20 | 37 | 32 | 40 | 76 |

| 5.0 | 19 | 30 | 43 | 36 | 54 | 86 |

| 8.0 | 21.7 | 33 | 50 | 43 | 55 | 110 |

| 10.0 | 20 | 33 | 52 | 48 | 60 | 121 |

| 15.0 | - | 36 | 67 | 60 | 64 | 130 |

| 20.0 | - | 48 | 77 | 72 | 90 | 162 |

| 30.0 | - | 56 | 94 | 78 | 100 | 177 |

Traditional Tiger Hooks

Tiger Hooks with new "EZ Check" 3 point marking system

Newer models of the TCB are fitted with the patent pending Tiger “EZ check” 3 point marking system. With this system a quick check that the A and B measurements are the same (as shown in the diagram below) will indicate if the hooks have stretched If A≦B the hook is fine; If A>B the hook needs to be replaced:

Tiger Adaptor Hoists are available with a drop-forged clevis adaptor allowing for the interchangeable range of EN1677 Tiger grade 100 clevis fittings.

This Tiger manufactured knuckle configuration gives 360° Rotation and 180° Pivot for maximum flexibility, whilst maintaining our 4:1 factor of safety at all angles.

- Available for Tiger TCB14 / SS12 chain blocks and PROLH / SS11 / TLH lever hoists.

- All fittings meet the standards of EN1677 grade 100 at 400°C tempering.

- Drop forged adaptor for maximum strength certified 4:1 FOS at all angles.

- Self-locking (safety) hook, clevis shackle, reevable egg (master) link or sling hook fitting available.

- Overload protection available.

- For lifting at angles (cross hauling/fleeting/drifting) with no deration.

- Chain Blocks – 500kg – 10t capacity.

- Lever Hoists – 800kg – 10t capacity.

Adaptor Sling Hook

Safety Hooks

Reevable Egg Link

Hoist Clevis Shackle

Adaptor Rotation

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.