-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Soft Lifting Slings

- Lifting Chain Slings

- Wire Rope Slings & Assemblies

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Beam Trolleys and Crane Bridges, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

-

Confined Space and Rescue Systems

- Xtirpa Confined Space Davit Arm Systems and Components

- Sala Advanced Davit Arm Systems and Components

- Genesi Confined Space Systems

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding Hoists & Rescue Winches

- Fall Arrest & Rescue Tripods

- Fall Arrest Davit Arms & Posts for Working at Height

-

Fall Arrest & Man-riding Systems

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

- Home/

- Lifting Equipment/

- Wire Rope Pulling Winches & Lifting Hoists/

- Hydraulic Wire Rope Winches / Hoists (Lifting and Pulling)/

- Tractel Hydraulic Pulling and Lifting Wire Rope Winches & Hoists/

- Tractel "TU16H" Hydraulic Tirfor (Supertirfor), Wire Rope Lifting & Pulling Winch - 1600kg

Tractel "TU16H" Hydraulic Tirfor (Supertirfor), Wire Rope Lifting & Pulling Winch - 1600kg

Optional Hydraulic power pack with electric or petrol motor.

THTW-4306

Lifting Capacities of 1600kg

The powered models of the TIRFOR machines complement the manual units for heavy loads, such as operating large work platforms, lifting shuttering, moving machinery, etc.

Depending on the application, the working conditions and the power available, powered operation can be electro-hydraulic or pneumatic.

Key Benefits:

- Saves time and labour.

- No operator fatique.

- Continuous operation.

- Increaded safety.

- One powerpack can power 4 Tirfor units all pulling/lifting the same load.

Multifunction:

Work can be performed in any position; horizontal, vertical or at an angle. There is no limit to the length of wire rope, the capacity can be increased.

Electric PowerPack

4 TU-16H Tirfors on 1 electric powerpack.

Safe and Reliable:

- Constant control of the load during lifting and lowering with accuracy to within one millimetre.

- When stationary the load is automotically distributed between the two jaw units.

- Overload safety device.

- TU range approved for lifting personnel in most countries.

Increased Capacity:

Using the sheave block technique, the capacity of the TIRFOR can be increased by a factor of 2,3,4 or more.

The figures given must be multiplied by the nominal capacity of the device.

When calculating the working load limit, include a loss of around 4% per sheave, due to the friction of the sheaves.

Applications

Construction, public works, civil engineering

- Moving and positioning formwork horizontally or vertically.

- Positioning sections of precast concrete beams.

- Lifting work platforms or suspended working platforms.

- Dragging, general lifting, guying, tensioning, etc…

Pipelaying and jointing

- Positioning of pipes for welding and jointing.

- Laying concrete pipes and pulling them together.

- Underwater pipeline assembly.

Bridges

- Positioning formwork.

- Guying.

- Pulling pre-cast concrete beams.

- Suspending inspection and maintenance platforms.

Steel structures

- Plumbing or aligning steel structure.

- Erecting steel silos.

Industry

- Installation and removal of machine tools and presses.

- Loading and unloading of heavy equipment.

- Lifting and pulling during maintenance operations.

Escalators, elevators

- Loading, unloading and rigging of prefabricated escalators.

- Lifting and positioning the cabins and drawing mechanisms.

Electricity and telecommunications

- Positioning transformers.

- Erection of mobile aerials and antennas.

- Tensioning underground and overhead cables.

- Guying operations.

Oil and chemical industries

- Controlled positioning and assembly of pipes and ducting.

- Guying silos and tanks during construction.

- Inspection and maintenance work.

Mines and quarries

- Handling and positioning equipment and underground machinery.

- Tensioning conveyors.

Shipbuilding and marine engineering

- Centering ships in dry dock.

- Anchoring barges and pushers.

Rail and road transport

- Lifting and removal of pylons and signals.

- Maintenance and tensioning of catenaries.

- Load binding heavy and difficult loads.

- Loading and unloading.

- De-bogging equipment.

Armed forces

- Many applications in the different sections of the Armed Forces (Engineering, Air Force, Artillery, Navy and Marines, signals and transportation).

Fire services and civil defence

- Removing crash wreckage.

- Handling and siting of emergency bridges.

Agriculture

- Controlling the direction of fall of a tree.

- Clearing trees and fences.

- Debrogging lorries, tractors and all mobile equipment.

- Tensioning fences.

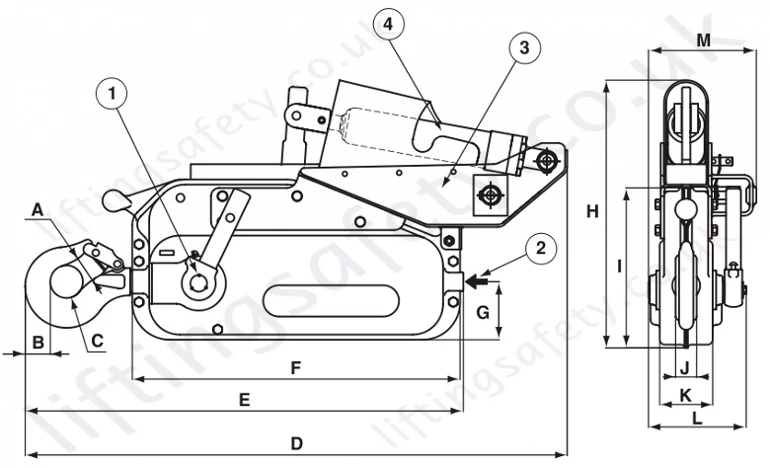

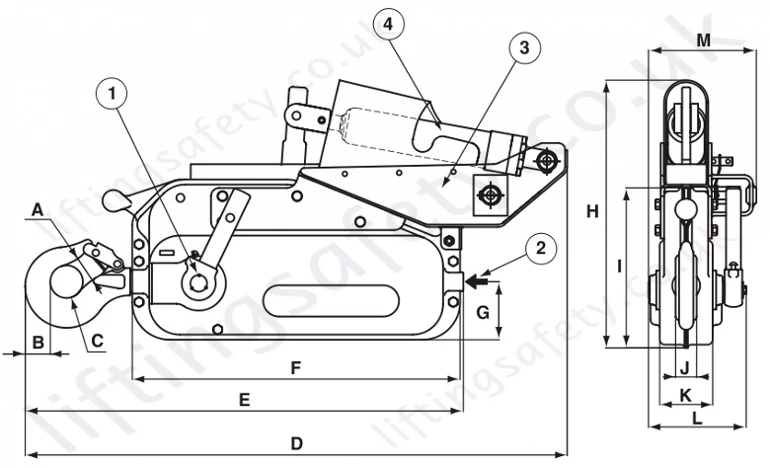

Dimensions.

- Shear pins forward.

- Rope guide.

- Ram fixing bracket.

- Hydraulic ram VA2.

| Model | SWL | Ø wire rope | Effort to control lever* | Rope travel* | Dimensions (mm) | Weight | ||||||||||||||

| daN/kg | (mm) | Forward (kg) | Reverse (kg) | Forward (mm) | Reverse (mm) | A | B | C | D | E | F | G | H | I | J | K | L | M | (kg) | |

| TU 16H | 1600 | 11.5 | 54 | 20 | 56 | 70 | 38 | 36 | 48 | 800 | 646 | 483 | 86 | 400 | 236 | 31 | 78 | 144 | 160 | 30 |

Lifting Capacities of 1600kg

The powered models of the TIRFOR machines complement the manual units for heavy loads, such as operating large work platforms, lifting shuttering, moving machinery, etc.

Depending on the application, the working conditions and the power available, powered operation can be electro-hydraulic or pneumatic.

Key Benefits:

- Saves time and labour.

- No operator fatique.

- Continuous operation.

- Increaded safety.

- One powerpack can power 4 Tirfor units all pulling/lifting the same load.

Multifunction:

Work can be performed in any position; horizontal, vertical or at an angle. There is no limit to the length of wire rope, the capacity can be increased.

Electric PowerPack

4 TU-16H Tirfors on 1 electric powerpack.

Safe and Reliable:

- Constant control of the load during lifting and lowering with accuracy to within one millimetre.

- When stationary the load is automotically distributed between the two jaw units.

- Overload safety device.

- TU range approved for lifting personnel in most countries.

Increased Capacity:

Using the sheave block technique, the capacity of the TIRFOR can be increased by a factor of 2,3,4 or more.

The figures given must be multiplied by the nominal capacity of the device.

When calculating the working load limit, include a loss of around 4% per sheave, due to the friction of the sheaves.

Applications

Construction, public works, civil engineering

- Moving and positioning formwork horizontally or vertically.

- Positioning sections of precast concrete beams.

- Lifting work platforms or suspended working platforms.

- Dragging, general lifting, guying, tensioning, etc…

Pipelaying and jointing

- Positioning of pipes for welding and jointing.

- Laying concrete pipes and pulling them together.

- Underwater pipeline assembly.

Bridges

- Positioning formwork.

- Guying.

- Pulling pre-cast concrete beams.

- Suspending inspection and maintenance platforms.

Steel structures

- Plumbing or aligning steel structure.

- Erecting steel silos.

Industry

- Installation and removal of machine tools and presses.

- Loading and unloading of heavy equipment.

- Lifting and pulling during maintenance operations.

Escalators, elevators

- Loading, unloading and rigging of prefabricated escalators.

- Lifting and positioning the cabins and drawing mechanisms.

Electricity and telecommunications

- Positioning transformers.

- Erection of mobile aerials and antennas.

- Tensioning underground and overhead cables.

- Guying operations.

Oil and chemical industries

- Controlled positioning and assembly of pipes and ducting.

- Guying silos and tanks during construction.

- Inspection and maintenance work.

Mines and quarries

- Handling and positioning equipment and underground machinery.

- Tensioning conveyors.

Shipbuilding and marine engineering

- Centering ships in dry dock.

- Anchoring barges and pushers.

Rail and road transport

- Lifting and removal of pylons and signals.

- Maintenance and tensioning of catenaries.

- Load binding heavy and difficult loads.

- Loading and unloading.

- De-bogging equipment.

Armed forces

- Many applications in the different sections of the Armed Forces (Engineering, Air Force, Artillery, Navy and Marines, signals and transportation).

Fire services and civil defence

- Removing crash wreckage.

- Handling and siting of emergency bridges.

Agriculture

- Controlling the direction of fall of a tree.

- Clearing trees and fences.

- Debrogging lorries, tractors and all mobile equipment.

- Tensioning fences.

Dimensions.

- Shear pins forward.

- Rope guide.

- Ram fixing bracket.

- Hydraulic ram VA2.

| Model | SWL | Ø wire rope | Effort to control lever* | Rope travel* | Dimensions (mm) | Weight | ||||||||||||||

| daN/kg | (mm) | Forward (kg) | Reverse (kg) | Forward (mm) | Reverse (mm) | A | B | C | D | E | F | G | H | I | J | K | L | M | (kg) | |

| TU 16H | 1600 | 11.5 | 54 | 20 | 56 | 70 | 38 | 36 | 48 | 800 | 646 | 483 | 86 | 400 | 236 | 31 | 78 | 144 | 160 | 30 |

You May Also Like

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.