-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Soft Lifting Slings

- Lifting Chain Slings

- Wire Rope Slings & Assemblies

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Beam Trolleys and Crane Bridges, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

-

Confined Space and Rescue Systems

- Xtirpa Confined Space Davit Arm Systems and Components

- Sala Advanced Davit Arm Systems and Components

- Genesi Confined Space Systems

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding Hoists & Rescue Winches

- Fall Arrest & Rescue Tripods

- Fall Arrest Davit Arms & Posts for Working at Height

-

Fall Arrest & Man-riding Systems

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

- Home/

- Lifting Equipment/

- Chain Hoists; Manual, Electric, Air/

- Lever Hoists/

- Yale Lever Hoists/

- Yale "Ergo360 UT" Utility Version Lever-Operated Hoist

Yale "Ergo360 UT" Utility Version Lever-Operated Hoist

Ergonomically designed, with revolutionary crank handle, auto safety device & 'chain claw' adjustable end stop. 1.5 tonne to 9 tonne.

Yale Ergo UT / YUUV-5133

The YaleERGO 360 ® UT is redefining the world of hoists for overhead line construction. The automatically acting safety gear, with a pending patent, once more increases the safety of use. Here, too, the ergonomic and safety enhancing design of the device and the revolutionary, patented hand lever enable efficient work at any angle, for lifting and pulling applications.

Automatically Acting Safety Gear

The YaleERGO 360® UT has a unique, automatically locking safety device to prevent a sudden drop (patent pending). It guarantees permanent monitoring and is active during operation as well as during inactive moments without the user having to activate it. In case of emergency, i.e. after failure of the load pressure brake and consequently exceeding the specified speed, the safety gear will automatically activate. It safely absorbs the load, preventing the creation of larger dynamic forces which could cause further damage. Due to its design, the device remains in a safe state even in the event of an error (e.g. rusted ratchet pawl, broken springs or other influences such as basic corrosion or dirt).

Patented Crank Handle

It guarantees the ideal power transmission for every application. Its folding lever-handle enables a working range of 360°, which increases productivity and reduces the risk of injury to the operator.

Direction Indicator in the Lever

A highly visible direction indicator located on the handle clearly shows the operating direction by means of arrow symbols.

Easy & Smooth Free Chaining

For quick take up and positioning of the slack chain – even with one hand. Designed not to accidentally free chain while under load.

Excellent Corrosion Protection

A housing optimized for outdoor applications (incl. water drainage holes on all sides) prevents a build up of water and the influence of moisture in extreme conditions (e.g. rain, fluctuations in temperature).

External components such as the chain guide and the stripper are zinc plated. Some of the internal moving parts such as the drive pinion, the ratchet pawl, the load chain wheel and the ratchet are MKS coated (Zinc flake coating).

Built to Last

Even with intensive use, the YaleERGO 360® UT impresses with its lightweight aluminium housing and high-quality bearings. The durable and high-quality powder coating of the surface offers additional protection in harsh environmental conditions.

Easy to Inspect Swivel Hooks

Forged Hooks and cast safety latches provide for a positive and secure load engagement, as they can yield without breaking. Bolt on hooks with nyloc nuts simplify the inspection process.

Requirements for the Redundant Safety Gear

In accordance with EN 1808 - Safety requirements for suspended access equipment, 8.9.2

- shall automatically engage in the event of overspeed (more than 0.5 m/s)

- the stopping distance must not exceed 500mm

- shall be capable of being reset

- shall be capable of being tested

- shall permit lifting at any time

In any cases the load is caught exceeding a speed of 0.5 m/s. Speeds below 0.5 m/s (corresponds to 2 km/h) are not safety relevant according to EN 1808.

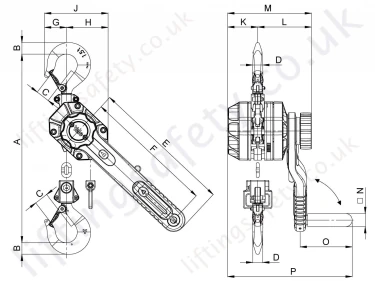

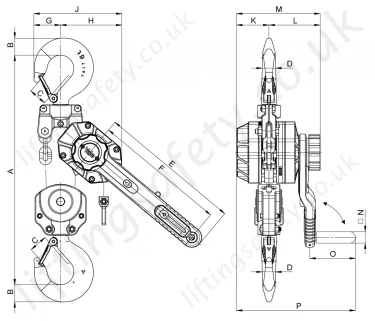

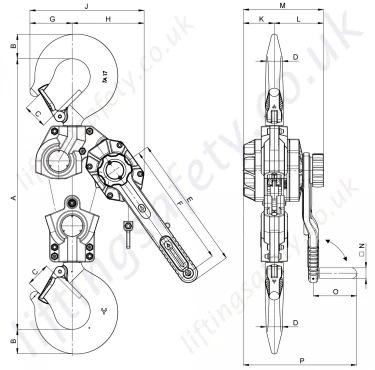

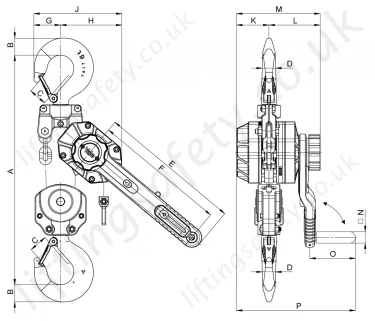

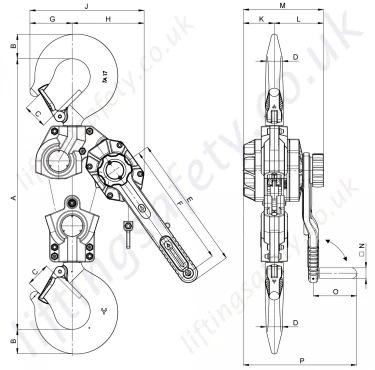

Dimensions & Specifications

| Model | Capacity (kg) | No. of Chain Falls | Weight @ Standard HOL (kg) |

| YaleERGO 360 UT 1500 | 1500 | 1 | 9.8 |

| YaleERGO 360 UT 3000 | 3000 | 1 | 18.1 |

| YaleERGO 360 UT 6000 | 6000 | 2 | 29.8 |

| YaleERGO 360 UT 9000 | 9000 | 3 | 50.4 |

|

|

|

| YaleERGO 360® UT, 1500 - 3000kg, single fall | YaleERGO 360® UT, 6000kg, double fall | YaleERGO 360® UT, 9000kg, three fall |

| Model | YaleERGO 360 UT 1500 | YaleERGO 360 UT 3000 | YaleERGO 360 UT 6000 | YaleERGO 360 UT 9000 |

| A min., mm | 375 | 445 | 563 | 695 |

| B, mm | 26 | 37 | 45 | 68 |

| C, mm | 31 | 40 | 47 | 68 |

| D, mm | 21 | 28 | 35 | 50 |

| E, mm | 327 | 377 | 377 | 377 |

| F, mm | 300 | 350 | 350 | 350 |

| G, mm | 51 | 57 | 71 | 116 |

| H, mm | 96 | 123 | 162 | 199 |

| J, mm | 147 | 180 | 233 | 315 |

| K, mm | 69 | 86 | 86 | 86 |

| L, mm | 124 | 136 | 136 | 136 |

| M, mm | 193 | 222 | 222 | 222 |

| N mm | 30 | 30 | 30 | 30 |

| O, mm | 120 | 120 | 120 | 120 |

| P, mm | 287 | 314 | 314 | 314 |

The YaleERGO 360® UT ratchet lever hoist with safety gear is a further development based on the already proven YaleERGO 360®.

The device was especially developed for the increased safety requirements in overhead line construction.

1. In which capacities is the YaleERGO 360® with safety gear available?

The YaleERGO 360® UT is available in capacities of 1500 - 3000 - 6000 and 9000kg.

2. What makes the YaleERGO 360® UT so unique?

The YaleERGO 360® UT has a unique, automatically locking safety device to prevent a sudden drop (patent pending). It guarantees permanent monitoring and is active during operation as well as during inactive moments without the user having to activate it. In case of emergency, i.e. after failure of the load pressure brake and the consequent exceeding of a specified speed, the safety gear automatically gets activated. It safely absorbs the load after only 25 – 50mm and thus prevents the creation of larger dynamic forces which could cause further damage.

Another highlight is the possibility of being able to lift at any time - even after the safety gear has been triggered due to safety reasons.By turning the hand lever by a full turn in lifting direction, the safety gear is automatically unlocked. It can then be returned to its original position at the push of a button. Due to its intrinsically design, the device remains in a safe state even in the event of an error (e.g. rusted ratchet pawl, broken springs or other influences such as basic corrosion or dirt).

3. External tests were carried out for the YaleERGO 360® UT and customer feedback was obtained. What was the result?

The function and resilience have been proven by various internal and external tests.

4. How is the YaleERGO 360® UT protected against environmental influences in overhead line construction?

The housing and hand lever are made of aluminium and have a powder coating. The housing is optimised for outdoor use and are designed with drain openings on all sides to prevent stagnant

water. All relevant components are zinc plated or MKS coated (Zinc flake coating.

5. Optional slip clutch (overload device) for the YaleERGO 360® UT

The slip clutch prevents damage to the unit, the handle rotates freely when hoist is overloaded. It reacts. When the permissible load capacity is exceeded by 25 %. Units with internal load limiter feature a black hand wheel for easy identification.

6. What kind of braking system is used on the YaleERGO 360® UT?

The YaleERGO 360® UT, like all our other manual hoists, uses the Weston load pressure brake. With this principle, the axial brake pressure is generated by the load itself and is therefore always proportional to the size of the load. The load is held securely in every position. When lowering, the brake is briefly released by operating the hand lever and closed again by the load slipping.

7. Chain release

Is installed as standard in all devices.

8. Are there safety bars on the hooks of the YaleERGO 360® UT?

Yes, cast safety brackets are standard on all YaleERGO hooks.

9. Which part of the hoist has a patent pending?

The automatically locking safety gear.

10. Who produces the YaleERGO 360® UT?

Manufactured in the company’s own factory in Hangzhou, PR China. Developed in Germany.

11. What is the surface of the housing of the YaleERGO 360® UT made of?

The YaleERGO 360® UT has a silver coloured powder coating for additional protection in harsh environmental conditions.

12. Chain claw

Due to the automatic safety gear, a constant readjustment of the chain stop and the chain claw during the work process is not necessary anymore! Fixing the chain with a chain stop is recommended if the device remains under load and unattended for a longer stretch of time, e.g. after interruptions of work or overnight!

Pricing

Availability

Usually 1-2 Working Days - 1pm cut-off

The YaleERGO 360 ® UT is redefining the world of hoists for overhead line construction. The automatically acting safety gear, with a pending patent, once more increases the safety of use. Here, too, the ergonomic and safety enhancing design of the device and the revolutionary, patented hand lever enable efficient work at any angle, for lifting and pulling applications.

Automatically Acting Safety Gear

The YaleERGO 360® UT has a unique, automatically locking safety device to prevent a sudden drop (patent pending). It guarantees permanent monitoring and is active during operation as well as during inactive moments without the user having to activate it. In case of emergency, i.e. after failure of the load pressure brake and consequently exceeding the specified speed, the safety gear will automatically activate. It safely absorbs the load, preventing the creation of larger dynamic forces which could cause further damage. Due to its design, the device remains in a safe state even in the event of an error (e.g. rusted ratchet pawl, broken springs or other influences such as basic corrosion or dirt).

Patented Crank Handle

It guarantees the ideal power transmission for every application. Its folding lever-handle enables a working range of 360°, which increases productivity and reduces the risk of injury to the operator.

Direction Indicator in the Lever

A highly visible direction indicator located on the handle clearly shows the operating direction by means of arrow symbols.

Easy & Smooth Free Chaining

For quick take up and positioning of the slack chain – even with one hand. Designed not to accidentally free chain while under load.

Excellent Corrosion Protection

A housing optimized for outdoor applications (incl. water drainage holes on all sides) prevents a build up of water and the influence of moisture in extreme conditions (e.g. rain, fluctuations in temperature).

External components such as the chain guide and the stripper are zinc plated. Some of the internal moving parts such as the drive pinion, the ratchet pawl, the load chain wheel and the ratchet are MKS coated (Zinc flake coating).

Built to Last

Even with intensive use, the YaleERGO 360® UT impresses with its lightweight aluminium housing and high-quality bearings. The durable and high-quality powder coating of the surface offers additional protection in harsh environmental conditions.

Easy to Inspect Swivel Hooks

Forged Hooks and cast safety latches provide for a positive and secure load engagement, as they can yield without breaking. Bolt on hooks with nyloc nuts simplify the inspection process.

Requirements for the Redundant Safety Gear

In accordance with EN 1808 - Safety requirements for suspended access equipment, 8.9.2

- shall automatically engage in the event of overspeed (more than 0.5 m/s)

- the stopping distance must not exceed 500mm

- shall be capable of being reset

- shall be capable of being tested

- shall permit lifting at any time

In any cases the load is caught exceeding a speed of 0.5 m/s. Speeds below 0.5 m/s (corresponds to 2 km/h) are not safety relevant according to EN 1808.

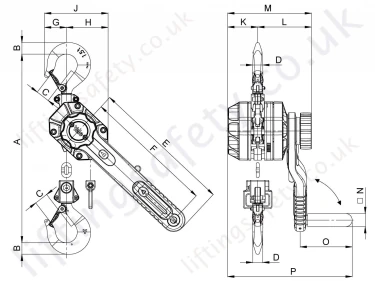

Dimensions & Specifications

| Model | Capacity (kg) | No. of Chain Falls | Weight @ Standard HOL (kg) |

| YaleERGO 360 UT 1500 | 1500 | 1 | 9.8 |

| YaleERGO 360 UT 3000 | 3000 | 1 | 18.1 |

| YaleERGO 360 UT 6000 | 6000 | 2 | 29.8 |

| YaleERGO 360 UT 9000 | 9000 | 3 | 50.4 |

|

|

|

| YaleERGO 360® UT, 1500 - 3000kg, single fall | YaleERGO 360® UT, 6000kg, double fall | YaleERGO 360® UT, 9000kg, three fall |

| Model | YaleERGO 360 UT 1500 | YaleERGO 360 UT 3000 | YaleERGO 360 UT 6000 | YaleERGO 360 UT 9000 |

| A min., mm | 375 | 445 | 563 | 695 |

| B, mm | 26 | 37 | 45 | 68 |

| C, mm | 31 | 40 | 47 | 68 |

| D, mm | 21 | 28 | 35 | 50 |

| E, mm | 327 | 377 | 377 | 377 |

| F, mm | 300 | 350 | 350 | 350 |

| G, mm | 51 | 57 | 71 | 116 |

| H, mm | 96 | 123 | 162 | 199 |

| J, mm | 147 | 180 | 233 | 315 |

| K, mm | 69 | 86 | 86 | 86 |

| L, mm | 124 | 136 | 136 | 136 |

| M, mm | 193 | 222 | 222 | 222 |

| N mm | 30 | 30 | 30 | 30 |

| O, mm | 120 | 120 | 120 | 120 |

| P, mm | 287 | 314 | 314 | 314 |

The YaleERGO 360® UT ratchet lever hoist with safety gear is a further development based on the already proven YaleERGO 360®.

The device was especially developed for the increased safety requirements in overhead line construction.

1. In which capacities is the YaleERGO 360® with safety gear available?

The YaleERGO 360® UT is available in capacities of 1500 - 3000 - 6000 and 9000kg.

2. What makes the YaleERGO 360® UT so unique?

The YaleERGO 360® UT has a unique, automatically locking safety device to prevent a sudden drop (patent pending). It guarantees permanent monitoring and is active during operation as well as during inactive moments without the user having to activate it. In case of emergency, i.e. after failure of the load pressure brake and the consequent exceeding of a specified speed, the safety gear automatically gets activated. It safely absorbs the load after only 25 – 50mm and thus prevents the creation of larger dynamic forces which could cause further damage.

Another highlight is the possibility of being able to lift at any time - even after the safety gear has been triggered due to safety reasons.By turning the hand lever by a full turn in lifting direction, the safety gear is automatically unlocked. It can then be returned to its original position at the push of a button. Due to its intrinsically design, the device remains in a safe state even in the event of an error (e.g. rusted ratchet pawl, broken springs or other influences such as basic corrosion or dirt).

3. External tests were carried out for the YaleERGO 360® UT and customer feedback was obtained. What was the result?

The function and resilience have been proven by various internal and external tests.

4. How is the YaleERGO 360® UT protected against environmental influences in overhead line construction?

The housing and hand lever are made of aluminium and have a powder coating. The housing is optimised for outdoor use and are designed with drain openings on all sides to prevent stagnant

water. All relevant components are zinc plated or MKS coated (Zinc flake coating.

5. Optional slip clutch (overload device) for the YaleERGO 360® UT

The slip clutch prevents damage to the unit, the handle rotates freely when hoist is overloaded. It reacts. When the permissible load capacity is exceeded by 25 %. Units with internal load limiter feature a black hand wheel for easy identification.

6. What kind of braking system is used on the YaleERGO 360® UT?

The YaleERGO 360® UT, like all our other manual hoists, uses the Weston load pressure brake. With this principle, the axial brake pressure is generated by the load itself and is therefore always proportional to the size of the load. The load is held securely in every position. When lowering, the brake is briefly released by operating the hand lever and closed again by the load slipping.

7. Chain release

Is installed as standard in all devices.

8. Are there safety bars on the hooks of the YaleERGO 360® UT?

Yes, cast safety brackets are standard on all YaleERGO hooks.

9. Which part of the hoist has a patent pending?

The automatically locking safety gear.

10. Who produces the YaleERGO 360® UT?

Manufactured in the company’s own factory in Hangzhou, PR China. Developed in Germany.

11. What is the surface of the housing of the YaleERGO 360® UT made of?

The YaleERGO 360® UT has a silver coloured powder coating for additional protection in harsh environmental conditions.

12. Chain claw

Due to the automatic safety gear, a constant readjustment of the chain stop and the chain claw during the work process is not necessary anymore! Fixing the chain with a chain stop is recommended if the device remains under load and unattended for a longer stretch of time, e.g. after interruptions of work or overnight!

You May Also Like

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.