-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Soft Lifting Slings

- Lifting Chain Slings

- Wire Rope Slings & Assemblies

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Beam Trolleys and Crane Bridges, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

-

Confined Space and Rescue Systems

- Xtirpa Confined Space Davit Arm Systems and Components

- Sala Advanced Davit Arm Systems and Components

- Genesi Confined Space Systems

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding Hoists & Rescue Winches

- Fall Arrest & Rescue Tripods

- Fall Arrest Davit Arms & Posts for Working at Height

-

Fall Arrest & Man-riding Systems

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

- Home/

- Lifting Equipment/

- General Industrial Lifting Equipment/

- Lifting Eye Bolts & Nuts/

- Swivel Eye Bolts/

- Codipro Swivel Lifting Points/

- Codipro "DSS" Double Swivel Shackle Lifting Point

Codipro "DSS" Double Swivel Shackle Lifting Point

Male bolt-on double articulated swivel load rings (hoist ring) with eye. Metric (M24-M100) or imperial (1"-2") thread. 4.5 to 32.1 tonne.

DSS UP / CSSS-4766

The universal lifting ring DSS is a double swivel ring. It is composed of a GRADUP lifting ring designed for rotations under load. Its double swivel ensures perfect alignment with the sling. The lifting ring swivels 180° but has a rotating range of 360°. It can be used for any lifting configuration (straigt lift, with angle, tilting, rotating).

The universal lifting ring DSS is approved for all lifting configurations from 0° to 90°, designed for use in a temperature range from -20°c to +200°c and carries various markings, including CE, WLL and tightening torque. It is manufactured in compliance with the REACH regulation and is also available as female, stainless-steel and welding version.

DSS lifting rings have a safety factor of 4 and 5, which means that their breaking load is four or five times greater than the capacity indicated in the technical sheet.

The DSS model is available in either male or female versions (FE.DSS).

DSS Features

- GRADUP steel ring

- Swivelling under load

- 360° rotation

- 180° articulation

- Safety factor of 5:1 and 4:1

- Zinc-coating (Stainless steel SS.DSS version also available up to M56 / 2" UNC.)

- Control anti-crack on 100% of products

- Fatigue tested

- Individual traceability number

- Use Coditracer to verify the authenticity of your Codipro lifting point or access user instructions, technical literature, angle load charts, the certificate of conformity, the inspection procedures or to guarantee your Codipro products.

- Other variants available on request, such as longer length bolts, custom thread forms (UNF, UNJ, BSP, BSF etc. - Any thread form is possible) or with flat or angular spacers.

- Delivery with certificate of compliance

- Tested to EN 1677-1

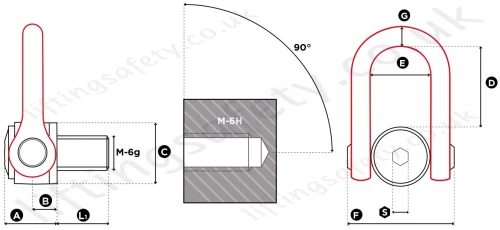

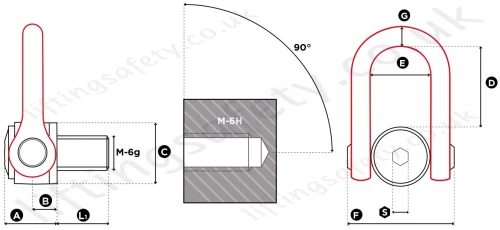

Dimensions & Specifications: DSS Metric Thread

All dimensions are in millimetres (mm)

| Reference | Thread Size | SF 5:1 WLL (t) | SF 4:1 WLL (t) | Standard L1 (mm) | Torque (Nm) | S | A | B | C | D | E | F | G | Weight (kg) |

| DSS M 24 UP | M24 (x3) | 4.5 | 5.5 | 36 | 160 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.4 |

| DSS M 30 UP | M30 (x3,5) | 7.7 | 8.5 | 45 | 250 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.5 |

| DSS M 33 UP | M33 (x3,5) | 8.5 | 10.5 | 50 | 250 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.5 |

| DSS M 36 UP | M36 (x4) | 11.0 | 12.0 | 54 | 320 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.5 |

| DSS M 36x3 UP | M36 (x3) | 11.0 | 12.0 | 54 | 320 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.5 |

| DSS M 39 UP | M39 (x4) | 12.0 | 14.0 | 58 | 320 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.7 |

| DSS M 42 UP | M42 (x4,5) | 13.0 | 15.0 | 63 | 400 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.8 |

| DSS M 42x3 UP | M42 (x3) | 13.0 | 15.0 | 63 | 400 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.8 |

| DSS M 45 UP | M45 (x4,5) | 14.5 | 16.0 | 63 | 400 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.9 |

| DSS M 48 UP | M48 (x5) | 17.0 | 20.0 | 68 | 600 | 19 | 79 | 38 | 90 | 125 | 91 | 182 | 45 | 11.0 |

| DSS M 48x3 UP | M48 (x3) | 17.0 | 20.0 | 68 | 600 | 19 | 79 | 38 | 90 | 125 | 91 | 182 | 45 | 11.0 |

| DSS M 48x4 UP | M48 (x4) | 17.0 | 20.0 | 68 | 600 | 19 | 79 | 38 | 90 | 125 | 91 | 182 | 45 | 11.0 |

| DSS M 52 UP | M52 (x5) | 19.0 | 20.0 | 68 | 600 | 19 | 79 | 38 | 90 | 125 | 91 | 182 | 45 | 11.2 |

| DSS M 56 UP | M56 (x5,5) | 22.0 | 25.0 | 78 | 600 | 19 | 79 | 38 | 90 | 125 | 91 | 182 | 45 | 11.3 |

| DSS M 56x4 UP | M56 (x4) | 22.0 | 25.0 | 78 | 600 | 19 | 79 | 38 | 90 | 125 | 91 | 182 | 45 | 11.4 |

| DSS M 64 UP | M64 (x6) | 25.0 | 32.1 | 90 | 600 | 19 | 79 | 38 | 95 | 125 | 91 | 182 | 45 | 12,2 |

| DSS M 64x4 UP | M64 (x4) | 25.0 | 32.1 | 90 | 600 | 19 | 79 | 38 | 95 | 125 | 91 | 182 | 45 | 12.2 |

| DSS M 72 UP | M72 (x6) | 22.0 | 25.0 | 90 | 600 | 19 | 79 | 38 | 95 | 125 | 91 | 182 | 45 | 14.0 |

| DSS M 72x4 UP | M72 (x4) | 22.0 | 25.0 | 90 | 600 | 19 | 79 | 38 | 95 | 125 | 91 | 182 | 45 | 14.0 |

| DSS M 80 UP | M80 (x6) | 25.0 | 32.1 | 90 | 600 | 19 | 79 | 38 | 100 | 125 | 91 | 182 | 45 | 15.0 |

| DSS M 90 UP | M90 (x6) | 25.0 | 32.1 | 90 | 600 | 19 | 79 | 38 | 100 | 125 | 91 | 182 | 45 | 15.5 |

| DSS M 100 UP | M100 (x6) | 25.0 | 32.1 | 90 | 600 | 19 | 79 | 38 | 110 | 125 | 91 | 182 | 45 | 16.5 |

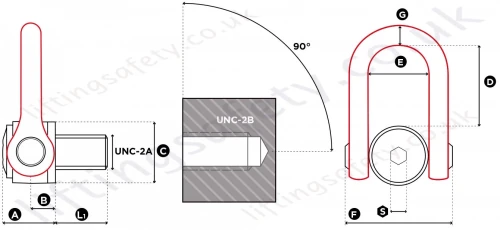

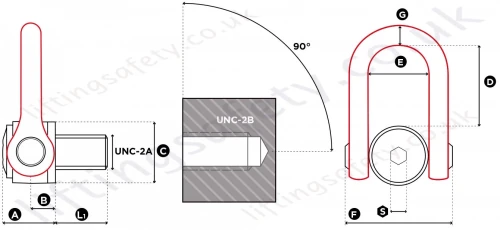

Dimensions & Specifications: DSS UNC Thread

All dimensions are in millimetres (mm)

| Reference | Thread Size | SF 5:1 WLL (lbs) | SF 4:1 WLL (lbs) | Standard L1 (mm) | Torque (ft-lb) | S | A | B | C | D | E | F | G | Weight (kg) |

| DSS U 100 UP | UNC 1’’-8 | 10,000 | 13,000 | 36 | 125 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.4 |

| DSS U 125 UP | UNC 1" 1/4-7 | 15,000 | 19,000 | 45 | 200 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.4 |

| DSS U 138 UP | UNC 1" 3/8-6 | 21,000 | 22,000 | 54 | 240 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.4 |

| DSS U 150 UP | UNC 1" 1/2-6 | 22,000 | 27,000 | 54 | 240 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.4 |

| DSS U 175 UP | UNC 1" 3/4-5 | 27,000 | 33,000 | 63 | 300 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.9 |

| DSS U 200 UP | UNC 2"-4,5 | 38,000 | 50,000 | 76 | 450 | 19 | 79 | 38 | 90 | 125 | 91 | 182 | 45 | 11.1 |

| DSS U 250 UP | UNC 2" 1/2-4 | 48,500 | 55,000 | 90 | 450 | 19 | 79 | 38 | 95 | 125 | 91 | 182 | 45 | 12.2 |

The CODIPRO team, always listening to the market and keeping an eye on its trends, works constantly to improve and develop its range of swivel lifting rings.

The GRADUP range has been especially developed to be the quintessential swivel lifting ring, particularly in terms of the quality of the raw materials used.

The CODIPRO research department, supported by advice from internationally renowned research centers, selected the best quality steel to achieve the best balance between tensile strength, breaking load and fatigue strength.

Each component of the GRADUP lifting rings’ hinge system has also been reviewed. The outer crowding dimensions, the screw couplings and the openings are compatible with CODIPRO lifting rings already on the market.

This major innovation, the GRADUP lifting ring, is the fruit of more than 40 years’ experience combined with in-depth research.

What are the benefits of the GRADUP range ?

- • Individually packed in a transparent, resealable pack containing the use recommendations and the certificate of compliance, each GRADUP lifting ring has an individual traceability number that is specific to CODIPRO.

- The GRADUP lifting rings are 100% compatible with lifting rings in the existing SEB, DSR, DSS ranges, etc. They are simply more effective.

- The optimization of the raw materials enables a significant improvement in WLL: up to 11% additional WLL (23% in safety factor 4).

- In keeping with its mission statement: “Our QUALITY = Your SAFETY”, CODIPRO is offering certified lifting rings stamped with the 5:1 safety factor, which means they can be used throughout the world, including in the USA. CODIPRO also provides all the information needed for use with a 4:1 safety factor, as defined under the EN 1677-1 standard.

- A lifting ring is intrinsically stronger when it is used linearly (= an angle of 0°). Under these conditions, the GRADUP lifting rings offer improved WLL, the values for which are defined in the tables at the end of the catalogue.

- An anti-corrosion coating means that the unpainted parts of the CODIPRO swivel lifting rings are resistant to salt mist spray for 600 hours.

- The tightening torque is stamped on all lifting rings in the GRADUP range.

- As a producer of lifting fittings, CODIPRO is especially concerned with the orange color (RAL 2002), which is always associated with SAFETY. This particular shade, which has been a feature of the CODIPRO brand for many years, allowing users to distinguish CODIPRO’s lifting rings from all the copies available on the market that could put operators’ lives in danger.

Grade 6, 8, 10, 12... Why GRADUP ?

The quality of the steel is the essential characteristic of a swivel lifting ring. In the world of lifting, it is normal to speak in terms of class of steel, or “grade”. This “grade” is what it’s all about for a chain, because the diameter of the chain combined with the class of the material is what gives the lifting capacity. In recent years, some “grades” that are higher than others have appeared on the market. Based on this, many manufacturers are offering lifting rings of class 10, 12, 14, etc. These descriptions are not relevant for lifting devices with multiple components, such as a swivel lifting ring. This is why CODIPRO is seeking to move away from this trend that is almost entirely based on marketing promotions.

By creating the GRADUP (or optimized grade) range, CODIPRO is offering a breakthrough innovation. In a swivel lifting ring with multiple components, each element is subject to different constraints. In order to offer maximum strength, each separate piece must be conceived so that the materials used and the design are the most appropriate for its function within the overall device. With the release of the GRADUP brand, CODIPRO is now offering an ultra-safe and ultra-high-performance lifting ring.

When can GRADUP be used ?

Anytime and anywhere in a traditional industrial environment: the GRADUP swivel lifting rings are designed to be used within a temperature range of -20°C to +200°C (-4°F to +392°F). Use

recommendations provided in 15 languages give a detailed description of the conditions for use.

For extreme applications such as offshore use, or very low/very high temperatures, etc., our engineers at the CODIPRO research department are available to provide details about the composition of our lifting rings: strength, chemical composition, mechanical strength, tensile strength, etc.

What certifications have been given to the GRADUP range ?

All CODIPRO swivel lifting rings comply strictly with the points in the Machinery Directive 2006/42/CE.

The EN 1677-1 standard (January 2009) applicable to “forged steel components of Grade 8” is restrictive with regard to the quality of the steel that can be used. With its innovative GRADUP range, CODIPRO has gone further, using higher-performance steels. CODIPRO has committed to complying with the essential points of the EN 1677-1 standard: the way in

which the components must be produced, tested and certified.

All lifting rings in the GRADUP range also comply with the ASME B30.26-2010 standard. They can be used in the USA with no specific safety measures.

Codipro DSS Product Datasheet

(approx. 0.5Mb)Load Angle Chart

(approx. 2.6Mb)User Instructions

(approx. 1.6Mb)DSS M 24 UP STEP File

(approx. 0.3Mb)DSS M 30 UP STEP File

(approx. 0.3Mb)DSS M 33 UP STEP File

(approx. 0.3Mb)DSS M 36 UP STEP File

(approx. 0.3Mb)DSS M 36x3 UP STEP File

(approx. 0.3Mb)DSS M 39 UP STEP File

(approx. 0.3Mb)DSS M 42 UP STEP File

(approx. 0.3Mb)DSS M 42x3 UP STEP File

(approx. 0.3Mb)DSS M 45 UP STEP File

(approx. 0.4Mb)DSS M 48 UP STEP File

(approx. 0.4Mb)DSS M 48x3 UP STEP File

(approx. 0.4Mb)DSS M 48x4 UP STEP File

(approx. 0.4Mb)DSS M 52 UP STEP File

(approx. 0.4Mb)DSS M 56 UP STEP File

(approx. 0.4Mb)DSS M 56x4 UP STEP File

(approx. 0.4Mb)DSS M 64 UP STEP File

(approx. 0.3Mb)DSS M 64x4 UP STEP File

(approx. 0.3Mb)DSS M 72 UP STEP File

(approx. 0.4Mb)DSS M 72x4 UP STEP File

(approx. 0.4Mb)DSS M 80 UP STEP File

(approx. 0.3Mb)DSS M 90 UP STEP File

(approx. 0.3Mb)DSS M 100 UP STEP File

(approx. 1.9Mb)DSS U 100 UP STEP File

(approx. 0.4Mb)DSS U 125 UP STEP File

(approx. 0.4Mb)DSS U 138 UP STEP File

(approx. 0.4Mb)DSS U 150 UP STEP File

(approx. 0.4Mb)DSS U 175 UP STEP File

(approx. 0.4Mb)DSS U 200 UP STEP File

(approx. 0.5Mb)DSS U 250 UP STEP File

(approx. 0.4Mb)The universal lifting ring DSS is a double swivel ring. It is composed of a GRADUP lifting ring designed for rotations under load. Its double swivel ensures perfect alignment with the sling. The lifting ring swivels 180° but has a rotating range of 360°. It can be used for any lifting configuration (straigt lift, with angle, tilting, rotating).

The universal lifting ring DSS is approved for all lifting configurations from 0° to 90°, designed for use in a temperature range from -20°c to +200°c and carries various markings, including CE, WLL and tightening torque. It is manufactured in compliance with the REACH regulation and is also available as female, stainless-steel and welding version.

DSS lifting rings have a safety factor of 4 and 5, which means that their breaking load is four or five times greater than the capacity indicated in the technical sheet.

The DSS model is available in either male or female versions (FE.DSS).

DSS Features

- GRADUP steel ring

- Swivelling under load

- 360° rotation

- 180° articulation

- Safety factor of 5:1 and 4:1

- Zinc-coating (Stainless steel SS.DSS version also available up to M56 / 2" UNC.)

- Control anti-crack on 100% of products

- Fatigue tested

- Individual traceability number

- Use Coditracer to verify the authenticity of your Codipro lifting point or access user instructions, technical literature, angle load charts, the certificate of conformity, the inspection procedures or to guarantee your Codipro products.

- Other variants available on request, such as longer length bolts, custom thread forms (UNF, UNJ, BSP, BSF etc. - Any thread form is possible) or with flat or angular spacers.

- Delivery with certificate of compliance

- Tested to EN 1677-1

Dimensions & Specifications: DSS Metric Thread

All dimensions are in millimetres (mm)

| Reference | Thread Size | SF 5:1 WLL (t) | SF 4:1 WLL (t) | Standard L1 (mm) | Torque (Nm) | S | A | B | C | D | E | F | G | Weight (kg) |

| DSS M 24 UP | M24 (x3) | 4.5 | 5.5 | 36 | 160 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.4 |

| DSS M 30 UP | M30 (x3,5) | 7.7 | 8.5 | 45 | 250 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.5 |

| DSS M 33 UP | M33 (x3,5) | 8.5 | 10.5 | 50 | 250 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.5 |

| DSS M 36 UP | M36 (x4) | 11.0 | 12.0 | 54 | 320 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.5 |

| DSS M 36x3 UP | M36 (x3) | 11.0 | 12.0 | 54 | 320 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.5 |

| DSS M 39 UP | M39 (x4) | 12.0 | 14.0 | 58 | 320 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.7 |

| DSS M 42 UP | M42 (x4,5) | 13.0 | 15.0 | 63 | 400 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.8 |

| DSS M 42x3 UP | M42 (x3) | 13.0 | 15.0 | 63 | 400 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.8 |

| DSS M 45 UP | M45 (x4,5) | 14.5 | 16.0 | 63 | 400 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.9 |

| DSS M 48 UP | M48 (x5) | 17.0 | 20.0 | 68 | 600 | 19 | 79 | 38 | 90 | 125 | 91 | 182 | 45 | 11.0 |

| DSS M 48x3 UP | M48 (x3) | 17.0 | 20.0 | 68 | 600 | 19 | 79 | 38 | 90 | 125 | 91 | 182 | 45 | 11.0 |

| DSS M 48x4 UP | M48 (x4) | 17.0 | 20.0 | 68 | 600 | 19 | 79 | 38 | 90 | 125 | 91 | 182 | 45 | 11.0 |

| DSS M 52 UP | M52 (x5) | 19.0 | 20.0 | 68 | 600 | 19 | 79 | 38 | 90 | 125 | 91 | 182 | 45 | 11.2 |

| DSS M 56 UP | M56 (x5,5) | 22.0 | 25.0 | 78 | 600 | 19 | 79 | 38 | 90 | 125 | 91 | 182 | 45 | 11.3 |

| DSS M 56x4 UP | M56 (x4) | 22.0 | 25.0 | 78 | 600 | 19 | 79 | 38 | 90 | 125 | 91 | 182 | 45 | 11.4 |

| DSS M 64 UP | M64 (x6) | 25.0 | 32.1 | 90 | 600 | 19 | 79 | 38 | 95 | 125 | 91 | 182 | 45 | 12,2 |

| DSS M 64x4 UP | M64 (x4) | 25.0 | 32.1 | 90 | 600 | 19 | 79 | 38 | 95 | 125 | 91 | 182 | 45 | 12.2 |

| DSS M 72 UP | M72 (x6) | 22.0 | 25.0 | 90 | 600 | 19 | 79 | 38 | 95 | 125 | 91 | 182 | 45 | 14.0 |

| DSS M 72x4 UP | M72 (x4) | 22.0 | 25.0 | 90 | 600 | 19 | 79 | 38 | 95 | 125 | 91 | 182 | 45 | 14.0 |

| DSS M 80 UP | M80 (x6) | 25.0 | 32.1 | 90 | 600 | 19 | 79 | 38 | 100 | 125 | 91 | 182 | 45 | 15.0 |

| DSS M 90 UP | M90 (x6) | 25.0 | 32.1 | 90 | 600 | 19 | 79 | 38 | 100 | 125 | 91 | 182 | 45 | 15.5 |

| DSS M 100 UP | M100 (x6) | 25.0 | 32.1 | 90 | 600 | 19 | 79 | 38 | 110 | 125 | 91 | 182 | 45 | 16.5 |

Dimensions & Specifications: DSS UNC Thread

All dimensions are in millimetres (mm)

| Reference | Thread Size | SF 5:1 WLL (lbs) | SF 4:1 WLL (lbs) | Standard L1 (mm) | Torque (ft-lb) | S | A | B | C | D | E | F | G | Weight (kg) |

| DSS U 100 UP | UNC 1’’-8 | 10,000 | 13,000 | 36 | 125 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.4 |

| DSS U 125 UP | UNC 1" 1/4-7 | 15,000 | 19,000 | 45 | 200 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.4 |

| DSS U 138 UP | UNC 1" 3/8-6 | 21,000 | 22,000 | 54 | 240 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.4 |

| DSS U 150 UP | UNC 1" 1/2-6 | 22,000 | 27,000 | 54 | 240 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.4 |

| DSS U 175 UP | UNC 1" 3/4-5 | 27,000 | 33,000 | 63 | 300 | 19 | 61 | 31 | 70 | 104 | 73 | 149 | 33 | 5.9 |

| DSS U 200 UP | UNC 2"-4,5 | 38,000 | 50,000 | 76 | 450 | 19 | 79 | 38 | 90 | 125 | 91 | 182 | 45 | 11.1 |

| DSS U 250 UP | UNC 2" 1/2-4 | 48,500 | 55,000 | 90 | 450 | 19 | 79 | 38 | 95 | 125 | 91 | 182 | 45 | 12.2 |

The CODIPRO team, always listening to the market and keeping an eye on its trends, works constantly to improve and develop its range of swivel lifting rings.

The GRADUP range has been especially developed to be the quintessential swivel lifting ring, particularly in terms of the quality of the raw materials used.

The CODIPRO research department, supported by advice from internationally renowned research centers, selected the best quality steel to achieve the best balance between tensile strength, breaking load and fatigue strength.

Each component of the GRADUP lifting rings’ hinge system has also been reviewed. The outer crowding dimensions, the screw couplings and the openings are compatible with CODIPRO lifting rings already on the market.

This major innovation, the GRADUP lifting ring, is the fruit of more than 40 years’ experience combined with in-depth research.

What are the benefits of the GRADUP range ?

- • Individually packed in a transparent, resealable pack containing the use recommendations and the certificate of compliance, each GRADUP lifting ring has an individual traceability number that is specific to CODIPRO.

- The GRADUP lifting rings are 100% compatible with lifting rings in the existing SEB, DSR, DSS ranges, etc. They are simply more effective.

- The optimization of the raw materials enables a significant improvement in WLL: up to 11% additional WLL (23% in safety factor 4).

- In keeping with its mission statement: “Our QUALITY = Your SAFETY”, CODIPRO is offering certified lifting rings stamped with the 5:1 safety factor, which means they can be used throughout the world, including in the USA. CODIPRO also provides all the information needed for use with a 4:1 safety factor, as defined under the EN 1677-1 standard.

- A lifting ring is intrinsically stronger when it is used linearly (= an angle of 0°). Under these conditions, the GRADUP lifting rings offer improved WLL, the values for which are defined in the tables at the end of the catalogue.

- An anti-corrosion coating means that the unpainted parts of the CODIPRO swivel lifting rings are resistant to salt mist spray for 600 hours.

- The tightening torque is stamped on all lifting rings in the GRADUP range.

- As a producer of lifting fittings, CODIPRO is especially concerned with the orange color (RAL 2002), which is always associated with SAFETY. This particular shade, which has been a feature of the CODIPRO brand for many years, allowing users to distinguish CODIPRO’s lifting rings from all the copies available on the market that could put operators’ lives in danger.

Grade 6, 8, 10, 12... Why GRADUP ?

The quality of the steel is the essential characteristic of a swivel lifting ring. In the world of lifting, it is normal to speak in terms of class of steel, or “grade”. This “grade” is what it’s all about for a chain, because the diameter of the chain combined with the class of the material is what gives the lifting capacity. In recent years, some “grades” that are higher than others have appeared on the market. Based on this, many manufacturers are offering lifting rings of class 10, 12, 14, etc. These descriptions are not relevant for lifting devices with multiple components, such as a swivel lifting ring. This is why CODIPRO is seeking to move away from this trend that is almost entirely based on marketing promotions.

By creating the GRADUP (or optimized grade) range, CODIPRO is offering a breakthrough innovation. In a swivel lifting ring with multiple components, each element is subject to different constraints. In order to offer maximum strength, each separate piece must be conceived so that the materials used and the design are the most appropriate for its function within the overall device. With the release of the GRADUP brand, CODIPRO is now offering an ultra-safe and ultra-high-performance lifting ring.

When can GRADUP be used ?

Anytime and anywhere in a traditional industrial environment: the GRADUP swivel lifting rings are designed to be used within a temperature range of -20°C to +200°C (-4°F to +392°F). Use

recommendations provided in 15 languages give a detailed description of the conditions for use.

For extreme applications such as offshore use, or very low/very high temperatures, etc., our engineers at the CODIPRO research department are available to provide details about the composition of our lifting rings: strength, chemical composition, mechanical strength, tensile strength, etc.

What certifications have been given to the GRADUP range ?

All CODIPRO swivel lifting rings comply strictly with the points in the Machinery Directive 2006/42/CE.

The EN 1677-1 standard (January 2009) applicable to “forged steel components of Grade 8” is restrictive with regard to the quality of the steel that can be used. With its innovative GRADUP range, CODIPRO has gone further, using higher-performance steels. CODIPRO has committed to complying with the essential points of the EN 1677-1 standard: the way in

which the components must be produced, tested and certified.

All lifting rings in the GRADUP range also comply with the ASME B30.26-2010 standard. They can be used in the USA with no specific safety measures.

Codipro DSS Product Datasheet

(approx. 0.5Mb)Load Angle Chart

(approx. 2.6Mb)User Instructions

(approx. 1.6Mb)DSS M 24 UP STEP File

(approx. 0.3Mb)DSS M 30 UP STEP File

(approx. 0.3Mb)DSS M 33 UP STEP File

(approx. 0.3Mb)DSS M 36 UP STEP File

(approx. 0.3Mb)DSS M 36x3 UP STEP File

(approx. 0.3Mb)DSS M 39 UP STEP File

(approx. 0.3Mb)DSS M 42 UP STEP File

(approx. 0.3Mb)DSS M 42x3 UP STEP File

(approx. 0.3Mb)DSS M 45 UP STEP File

(approx. 0.4Mb)DSS M 48 UP STEP File

(approx. 0.4Mb)DSS M 48x3 UP STEP File

(approx. 0.4Mb)DSS M 48x4 UP STEP File

(approx. 0.4Mb)DSS M 52 UP STEP File

(approx. 0.4Mb)DSS M 56 UP STEP File

(approx. 0.4Mb)DSS M 56x4 UP STEP File

(approx. 0.4Mb)DSS M 64 UP STEP File

(approx. 0.3Mb)DSS M 64x4 UP STEP File

(approx. 0.3Mb)DSS M 72 UP STEP File

(approx. 0.4Mb)DSS M 72x4 UP STEP File

(approx. 0.4Mb)DSS M 80 UP STEP File

(approx. 0.3Mb)DSS M 90 UP STEP File

(approx. 0.3Mb)DSS M 100 UP STEP File

(approx. 1.9Mb)DSS U 100 UP STEP File

(approx. 0.4Mb)DSS U 125 UP STEP File

(approx. 0.4Mb)DSS U 138 UP STEP File

(approx. 0.4Mb)DSS U 150 UP STEP File

(approx. 0.4Mb)DSS U 175 UP STEP File

(approx. 0.4Mb)DSS U 200 UP STEP File

(approx. 0.5Mb)DSS U 250 UP STEP File

(approx. 0.4Mb)You May Also Like

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.