-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Soft Lifting Slings

- Lifting Chain Slings

- Wire Rope Slings & Assemblies

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Beam Trolleys and Crane Bridges, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

-

Confined Space and Rescue Systems

- Xtirpa Confined Space Davit Arm Systems and Components

- Sala Advanced Davit Arm Systems and Components

- Genesi Confined Space Systems

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding Hoists & Rescue Winches

- Fall Arrest & Rescue Tripods

- Fall Arrest Davit Arms & Posts for Working at Height

-

Fall Arrest & Man-riding Systems

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

- Home/

- Lifting Equipment/

- General Industrial Lifting Equipment/

- Lifting Magnets, Permanent, Battery Electric and Manual/

- Permanent Lifting Magnets; Mechanical (Lever) Operation (No power needed) to 5000kg/

- Eclipse ULE (UltraLift E) Permanent Lifting Magnet - Range from 100kg to 1000kg

Eclipse ULE (UltraLift E) Permanent Lifting Magnet - Range from 100kg to 1000kg

Economy lever operated permanent magnet for flat material or round bar.

UltraLift E / EULM-5419

The UltraLift E lifter range is a performance lifter for safely lifting ferrous plate and round bar, with a 3:1 WLL design and a Locking Safety Mechanism for the manual lever to make the lift safer. The performance of these units is always application specific.

Features

- 3:1 WLL - safely lift ferrous material

- Lifts up to 1000kg Flat Plate*

- Lifts up to 500kg Round Bar*

- Lever to manually Switch ‘On’ and ‘Off’

Never exceed the WLL (Working Load Limit) - formerly the SWL (Safe Working Load). The Safety Factor for lifting is 3:1 for this range. Always use LOLER, PUWER, ASME B30.20 and H&S advice.

The UltraLift E range is used to lift ferrous sheets and ferrous round bar. Depending on the version, the UltraLift E can be used on minimum ferrous plate thickness from 7.5mm thick (bearing in mind that the thinner the plate the less the holding force achieved will be). For safely lifting thinner plate and sheet, please use the UltraLift TP range.

Flat Plate

The WLL* varies from up to 100kg for the ULE0100 rising to up to 1000kg (2200lb) for the ULE1000 when used on ferrous flat plate.

Round Bar

The WLL* varies from up to 50kg for the ULE0100 (80mm maximum diameter) rising to up to 500kg for the ULE1000 (180mm maximum diameter) when used on ferrous round bar (diameter limits apply for each version).

Do not use any lifter if it appears to be damaged. Inspect the lifter at least annually. We can inspect and service/repair our Lifters for you.

Benefits

- No Power Supply required

- 3:1 Safety Factor for lifting

- Lifts Ferrous Plate up to 1000kg*

- Lifts Ferrous Round Bar up to 500kg*

- Locking switch handle safety mechanism

Performance

- Magnetic Performance: Up to 1000kg WLL (value varies with thickness and/or diameter) - see table below

- Magnet Type: Permanent Magnet Lifter

- Temperature Range: -10°C to +40°C (14°F to +104°F)

- Humidity Tolerance: 80%

Materials

- Magnet Material Rare earth neodymium iron boron (NdFeB)

- End plates Aluminium - painted

- Housing Mild steel

- Pole feet Mild steel

Maintenance

- As part of LOLER, PUWER, ASME B30.20 and H&S advice, you need to regularly inspect Lifters to ensure they are not damaged and are suitable for lifting the parts.

- Annual inspection is a minimum requirement

Suitability

- Suitable Products Ferrous materials (e.g. mild steel)

- Suitable Location Example - factory shopfloor / production line

Conformity

- The Supply of Machinery (Safety) Regulations 2008

- The Electrical Equipment (Safety) Regulations 2016

- The Electromagnetic Compatibility Regulations 2016

- LOLER Regulations 1998

Designated standards: EN ISO 12100:2010, EN 13854:2019, EN 13155:2020

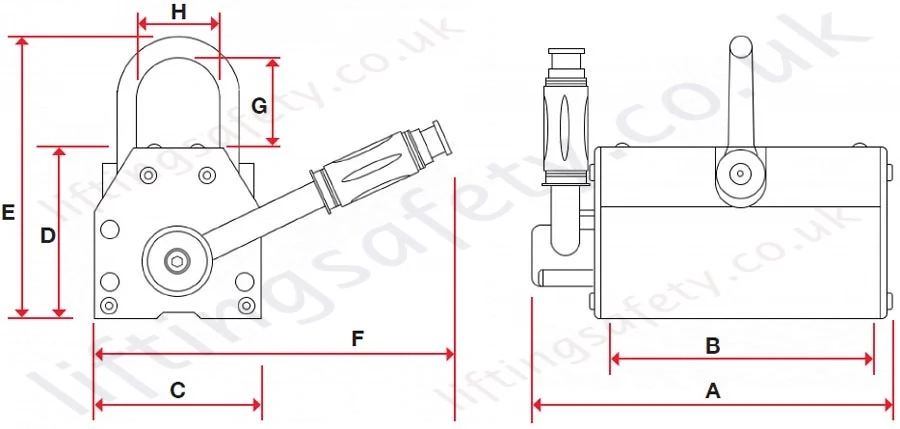

Specifications

| Part Number | Dimensions (mm) | Self-Weight (kg) | Flat Plate/Section WLL* (kg) | Flat Plate/Section Minimum Thickness (mm) | Maximum Material Length (mm) | Round Bar WLL* (kg) | Round Bar Maximum Diameter (mm) | |||||||

| A | B | C | D | E | F | G | H | |||||||

| ULE0100 | 131 | 91 | 65 | 75 | 124 | 185 | 45 | 32 | 3 | 100 | 15 | 1000 | 50 | 80 |

| ULE0300 | 202 | 157 | 95 | 95 | 169 | 253 | 63 | 46 | 10 | 300 | 20 | 1500 | 150 | 100 |

| ULE0600 | 283 | 248 | 120 | 118 | 220 | 280 | 90 | 61 | 23 | 600 | 30 | 2000 | 300 | 140 |

| ULE1000 | 350 | 308 | 136 | 140 | 269 | 310 | 110 | 79 | 39 | 1000 | 40 | 2500 | 500 | 180 |

*Please note that the Working Load Limit (WLL) is now used instead of Safe Working Load (SWL). The Lifting force values shown include the 3:1 safety factor and have been based on using thick high magnetic permeability steel with no air gaps. Air gaps, thinner materials and materials with lower magnetic permeability can all reduce the pull force a lifter can actually achieve. Please note that the achievable pull force is reduced when lifting thinner mild steel plate. Please note that the diameter of the round bar can affect the amount of lift that can be achieved. You must follow LOLER, PUWER, ASME B30.20 and H&S advice. You should always check for a downrate, factor in any downrate to then perform a safety lift, then perform a full lift only after a successful safety lift.

Pricing

The UltraLift E lifter range is a performance lifter for safely lifting ferrous plate and round bar, with a 3:1 WLL design and a Locking Safety Mechanism for the manual lever to make the lift safer. The performance of these units is always application specific.

Features

- 3:1 WLL - safely lift ferrous material

- Lifts up to 1000kg Flat Plate*

- Lifts up to 500kg Round Bar*

- Lever to manually Switch ‘On’ and ‘Off’

Never exceed the WLL (Working Load Limit) - formerly the SWL (Safe Working Load). The Safety Factor for lifting is 3:1 for this range. Always use LOLER, PUWER, ASME B30.20 and H&S advice.

The UltraLift E range is used to lift ferrous sheets and ferrous round bar. Depending on the version, the UltraLift E can be used on minimum ferrous plate thickness from 7.5mm thick (bearing in mind that the thinner the plate the less the holding force achieved will be). For safely lifting thinner plate and sheet, please use the UltraLift TP range.

Flat Plate

The WLL* varies from up to 100kg for the ULE0100 rising to up to 1000kg (2200lb) for the ULE1000 when used on ferrous flat plate.

Round Bar

The WLL* varies from up to 50kg for the ULE0100 (80mm maximum diameter) rising to up to 500kg for the ULE1000 (180mm maximum diameter) when used on ferrous round bar (diameter limits apply for each version).

Do not use any lifter if it appears to be damaged. Inspect the lifter at least annually. We can inspect and service/repair our Lifters for you.

Benefits

- No Power Supply required

- 3:1 Safety Factor for lifting

- Lifts Ferrous Plate up to 1000kg*

- Lifts Ferrous Round Bar up to 500kg*

- Locking switch handle safety mechanism

Performance

- Magnetic Performance: Up to 1000kg WLL (value varies with thickness and/or diameter) - see table below

- Magnet Type: Permanent Magnet Lifter

- Temperature Range: -10°C to +40°C (14°F to +104°F)

- Humidity Tolerance: 80%

Materials

- Magnet Material Rare earth neodymium iron boron (NdFeB)

- End plates Aluminium - painted

- Housing Mild steel

- Pole feet Mild steel

Maintenance

- As part of LOLER, PUWER, ASME B30.20 and H&S advice, you need to regularly inspect Lifters to ensure they are not damaged and are suitable for lifting the parts.

- Annual inspection is a minimum requirement

Suitability

- Suitable Products Ferrous materials (e.g. mild steel)

- Suitable Location Example - factory shopfloor / production line

Conformity

- The Supply of Machinery (Safety) Regulations 2008

- The Electrical Equipment (Safety) Regulations 2016

- The Electromagnetic Compatibility Regulations 2016

- LOLER Regulations 1998

Designated standards: EN ISO 12100:2010, EN 13854:2019, EN 13155:2020

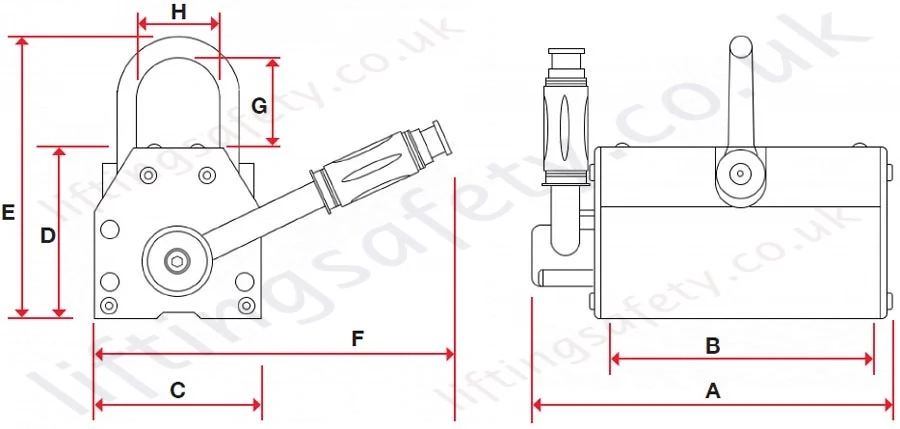

Specifications

| Part Number | Dimensions (mm) | Self-Weight (kg) | Flat Plate/Section WLL* (kg) | Flat Plate/Section Minimum Thickness (mm) | Maximum Material Length (mm) | Round Bar WLL* (kg) | Round Bar Maximum Diameter (mm) | |||||||

| A | B | C | D | E | F | G | H | |||||||

| ULE0100 | 131 | 91 | 65 | 75 | 124 | 185 | 45 | 32 | 3 | 100 | 15 | 1000 | 50 | 80 |

| ULE0300 | 202 | 157 | 95 | 95 | 169 | 253 | 63 | 46 | 10 | 300 | 20 | 1500 | 150 | 100 |

| ULE0600 | 283 | 248 | 120 | 118 | 220 | 280 | 90 | 61 | 23 | 600 | 30 | 2000 | 300 | 140 |

| ULE1000 | 350 | 308 | 136 | 140 | 269 | 310 | 110 | 79 | 39 | 1000 | 40 | 2500 | 500 | 180 |

*Please note that the Working Load Limit (WLL) is now used instead of Safe Working Load (SWL). The Lifting force values shown include the 3:1 safety factor and have been based on using thick high magnetic permeability steel with no air gaps. Air gaps, thinner materials and materials with lower magnetic permeability can all reduce the pull force a lifter can actually achieve. Please note that the achievable pull force is reduced when lifting thinner mild steel plate. Please note that the diameter of the round bar can affect the amount of lift that can be achieved. You must follow LOLER, PUWER, ASME B30.20 and H&S advice. You should always check for a downrate, factor in any downrate to then perform a safety lift, then perform a full lift only after a successful safety lift.

You May Also Like

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.