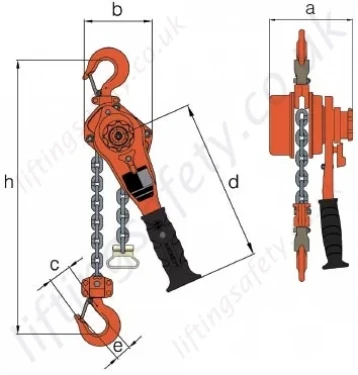

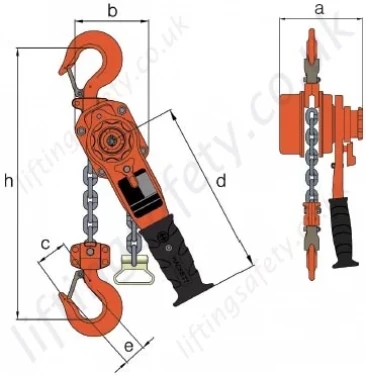

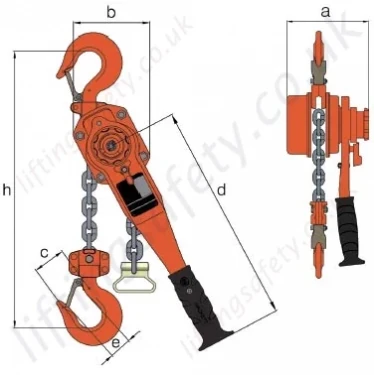

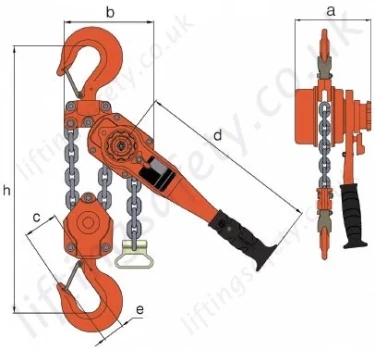

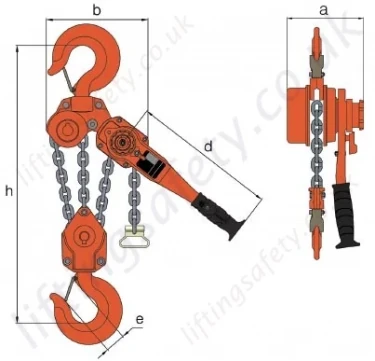

William Hackett "L4" Lever Hoist

Meets and exceeds the requirements of international standards BS EN13157:2004 + AI:2009, ASME B30.21-2014, AS1418.2-1997, SANS 1636:2-2007. 750kg to 20 tonne.

Model:

L4 and L4 Compact Series / LLH-4544

Usually 1-2 Working Days - 1pm cut-off