-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Fibre Lifting Slings

- Chain Slings & Components

- Lifting and Lashing Chain

- Wire Rope Slings & Assemblies

- Shackles

- Eye Bolts and Eye Nuts

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Runway Beam Monorail Crane Trolleys, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms and Jib Cranes

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

- Man-riding Hoists & Rescue Winches

-

Fall Arrest & Man-riding Systems

- Fall Arrest Davit Arms & Posts for Working at Height

- Sala Advanced Davit Arm Systems and Components

- Xtirpa Confined Space Davit Arm Systems and Components

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding & Rescue Tripods & Quadpods

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

- Home/

- Lifting Equipment/

- Chain Hoists; Manual, Electric, Air/

- Hand Chain Blocks/

- Atex Manual Chain Blocks/

- Yale "YL ITP SR" Atex Chain Block with Plain Beam Trolley

Yale "YL ITP SR" Atex Chain Block with Plain Beam Trolley

Spark resistant manual hand chain hoist with built-in push travel beam trolley.

Yalelift ITP SR / SRH-1122

Yalelift ITP SR Chain Hoist with Push Travel Trolley

Similar to the Yalelift 360 SR chain block, but with and integral push travel beam trolley as opposed to the standard hook suspension. The advantage of this built-in design rather then hooking the chain hoist in to the trolley suspension eye of a manual trolley, the hoists headroom (bearing point of wheels, to raised hook of the hoist unit) is reduced, allowing more versatility in low head room applications where space is restricted. There are 2 main disadvantages to the trolley being in-built, which are; the hoist and trolley must be handled and installed as a single piece, which means that the trolley-hoist combination would be heavier to install than a trolley alone, which the hoist could then be hooked in to afterwards. The second dissadvantage being that with an permanently fitted trolley, the hoist could not then be used for other applications, such as hooking in to beam clamps. If your preference is a seperate hoist and trolley, then the Yale HTP / HTG SR beam trolley would probably be of interest.

500kg, 1000kg, 2000kg, 3000kg and 5000kg capacity options available.

Spark Protection/Resistant Features

- Stainless steel hand chain.

- Units completely corrosion resistant.

- Bronze-plated suspension and load hooks.

- Solid bronze trolley wheels.

- Rubber Buffers.

- Chain containers.

Corrosion protection

- Corrosion starts on the surface of components due to reaction of environmental influences. This affects the mechanical properties of the components, e.g. breaking strength and total ultimate elongation.

- Many components are supplied in black (un-machined),bright (machined) or painted condition.

- This offers certain protection but does not protect against corrosion.

- With the application of a protective coating, the onset of corrosion can be delayed, thus extending the service life of the treated components.

More Information:

The combination of the Yalelift 360 with a low headroom manual trolley provides even more flexibility in the application of the Yalelift 360.

- All units of this series up to a capacity of 3000kg are provided with a single chain fall and the minimum headroom has been further reduced. Ideal for applications with low ceiling and limited headroom.

- The manual trolley is adjustable to fit a wide range of beam profiles (e.g. INP, IPE, IPB). Depending on the beam flange width, an adjustment up to 300mm can be made easily.

- The trolley wheels are designed for a maximum beam profile incline of 14% (DIN 1025 - part 1), excellent rolling features are guaranteed by pre-lubricated, encapsulated ball bearings.

- Anti-tilt and anti-drop devices are standard.

- A subsequent conversion of a Yalelift 360 into a Yalelift IT with integrated trolley is easily possible at any time.

Specification

Paint shops, foundries, petrochemical industries, refineries, automobile factories, ships, docks, printers, textile plants, paper factories and environments where gas and dust is present.

| Capacity (SWL) | Fall of load chain | Lifting height (m) | Beam Width | Closed height (mm) | |||

| Type A (mm) | Weight (kg) | Type B (mm) | Weight (kg) | ||||

| 500kg | 1 | 3 | 50 - 180 | 20 | 180 - 300 | 21 | 245 |

| 1000kg | 1 | 3 | 50 - 180 | 27 | 180 - 300 | 29 | 272 |

| 2000kg | 1 | 3 | 58 - 180 | 44 | 180 - 300 | 46 | 323 |

| Discontinued - 3000kg | 1 | 3 | 74 - 180 | 77 | 180 - 300 | 79 | 382 |

| Discontinued - 5000kg | 2 | 3 | 98 - 180 | 125 | 180 - 300 | 129 | 550 |

Yale ATEX Levels of Protection

All of Yale’s ATEX hoists meet the following standards: EN1127-1:1997; EN13463-1:2001; EN13463-5:2003, and are supplied complete with the relevant ATEX approval documentation.

Yale (Columbus McKinnon) offer three levels of protection - BASIC, MEDIUM, and HIGH.

Under directive 94/9/EC, equipment for areas with an explosion hazard are assigned to groups, categories and temperature classes. This is necessary as the requirements for equipment need not be the same for every application and for every hazard classification.

NB: It is the responsibility of the end user to identify the explosion proof classification required, NOT the hoist manufacturer or the supplier. Reference Directive 99/92/EC.

|

MEDIUM (Zone 1/21 & 2/22) ATEX II 2 G Ex h IIB T4ATEX II 2 D Ex h IIIB T135°C Db |

HIGH (Zone 1/21 & 2/22) ATEX II 2 G Ex h IIC T4 GbATEX II 2 D Ex h IIIC T135°C Db |

|

|

Why explosion protection?

Explosion protection for electrical and mechanical machinery is an important precautionary measure to ensure the safety of persons and all kinds of production, storage and distribution systems, when explosive mixtures of combustible gases, dusts and air may occur.

What does explosion protection achieve?

Explosion protection can mean to generally prevent the ignition of an explosive mixture. Explosion protection can also be achieved by eliminating potential ignition sources in advance, e.g. high temperatures and sparking. In many trades and industries, combustible gases, vapours and dusts are handled which have the potential to cause explosions.

Examples of explosion hazards in various industries

- Chemical industry

- Waste disposal sites

- Energy production companies

- Waste management companies

- Gas suppliers

- Metal processing companies

- Wood-processing companies

- Paint shops

- Agriculture

- Food and feed-stuffs industry

- Pharmaceutical industry

- Refineries

- Recycling companies

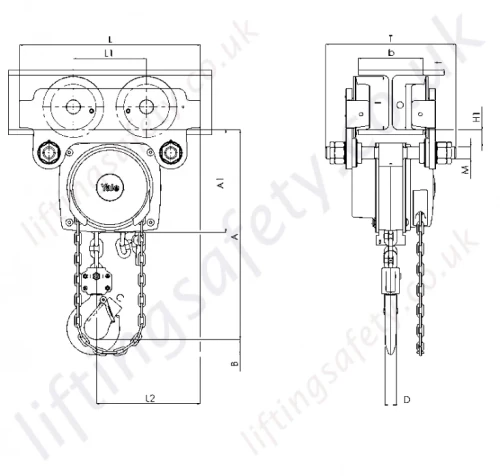

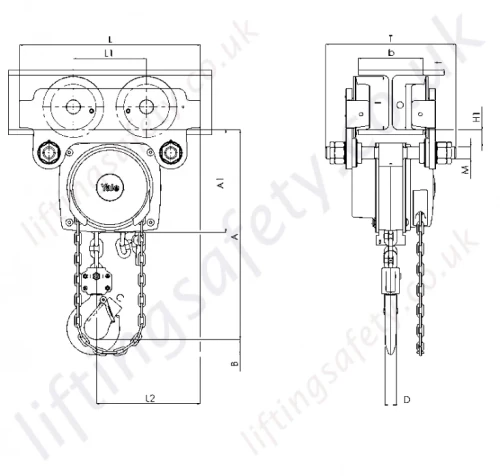

Yalelift ITP Integral Push Trolley Hoists - ATEX. Capacities 0.5t to 2.0t

| Model | YLIT ATEX 500 | YLIT ATEX 1000 | YLIT ATEX 2000 |

| A min. (mm) | 245 | 272 | 323 |

| A1 (mm) | 158 | 178 | 205.5 |

| A2 (mm) | – | – | – |

| B (mm) | 17 | 22 | 30 |

| C (mm) | 24 | 29 | 35 |

| D (mm) | 14 | 19 | 22 |

| F (Geared trolley) (mm) | 92 | 92 | 91 |

| H1 (mm) | 24.5 | 24 | 23.5 |

| I (Push trolley) (mm) | 71.5 | 71.5 | 95.5 |

| I (Geared trolley) (mm) | 76.5 | 76.5 | 98 |

| L (mm) | 270 | 310 | 360 |

| L1 (mm) | 130 | 130 | 150 |

| L2 (mm) | 159 | 175 | 207 |

| M (mm) | M 18 | M 22 | M 27 |

| O (mm) | 60 | 60 | 80 |

| P (Geared trolley) (mm) | 108 | 110 | 112 |

| T (Area A) (mm) | 280 | 290 | 305 |

| T (Area B) (mm) | 400 | 410 | 425 |

| No. of Chain Falls | 1 | 1 | 1 |

| Beam Flange Thickness Max. (mm) | 19 | 19 | 19 |

| Curve Radius Min. (m) | 0.9 | 0.9 | 1.15 |

| Weight @ 3m HOL (kg) - Type 'A' Trolley | 20 | 27 | 44 |

Pricing

Yalelift ITP SR Chain Hoist with Push Travel Trolley

Similar to the Yalelift 360 SR chain block, but with and integral push travel beam trolley as opposed to the standard hook suspension. The advantage of this built-in design rather then hooking the chain hoist in to the trolley suspension eye of a manual trolley, the hoists headroom (bearing point of wheels, to raised hook of the hoist unit) is reduced, allowing more versatility in low head room applications where space is restricted. There are 2 main disadvantages to the trolley being in-built, which are; the hoist and trolley must be handled and installed as a single piece, which means that the trolley-hoist combination would be heavier to install than a trolley alone, which the hoist could then be hooked in to afterwards. The second dissadvantage being that with an permanently fitted trolley, the hoist could not then be used for other applications, such as hooking in to beam clamps. If your preference is a seperate hoist and trolley, then the Yale HTP / HTG SR beam trolley would probably be of interest.

500kg, 1000kg, 2000kg, 3000kg and 5000kg capacity options available.

Spark Protection/Resistant Features

- Stainless steel hand chain.

- Units completely corrosion resistant.

- Bronze-plated suspension and load hooks.

- Solid bronze trolley wheels.

- Rubber Buffers.

- Chain containers.

Corrosion protection

- Corrosion starts on the surface of components due to reaction of environmental influences. This affects the mechanical properties of the components, e.g. breaking strength and total ultimate elongation.

- Many components are supplied in black (un-machined),bright (machined) or painted condition.

- This offers certain protection but does not protect against corrosion.

- With the application of a protective coating, the onset of corrosion can be delayed, thus extending the service life of the treated components.

More Information:

The combination of the Yalelift 360 with a low headroom manual trolley provides even more flexibility in the application of the Yalelift 360.

- All units of this series up to a capacity of 3000kg are provided with a single chain fall and the minimum headroom has been further reduced. Ideal for applications with low ceiling and limited headroom.

- The manual trolley is adjustable to fit a wide range of beam profiles (e.g. INP, IPE, IPB). Depending on the beam flange width, an adjustment up to 300mm can be made easily.

- The trolley wheels are designed for a maximum beam profile incline of 14% (DIN 1025 - part 1), excellent rolling features are guaranteed by pre-lubricated, encapsulated ball bearings.

- Anti-tilt and anti-drop devices are standard.

- A subsequent conversion of a Yalelift 360 into a Yalelift IT with integrated trolley is easily possible at any time.

Specification

Paint shops, foundries, petrochemical industries, refineries, automobile factories, ships, docks, printers, textile plants, paper factories and environments where gas and dust is present.

| Capacity (SWL) | Fall of load chain | Lifting height (m) | Beam Width | Closed height (mm) | |||

| Type A (mm) | Weight (kg) | Type B (mm) | Weight (kg) | ||||

| 500kg | 1 | 3 | 50 - 180 | 20 | 180 - 300 | 21 | 245 |

| 1000kg | 1 | 3 | 50 - 180 | 27 | 180 - 300 | 29 | 272 |

| 2000kg | 1 | 3 | 58 - 180 | 44 | 180 - 300 | 46 | 323 |

| Discontinued - 3000kg | 1 | 3 | 74 - 180 | 77 | 180 - 300 | 79 | 382 |

| Discontinued - 5000kg | 2 | 3 | 98 - 180 | 125 | 180 - 300 | 129 | 550 |

Yale ATEX Levels of Protection

All of Yale’s ATEX hoists meet the following standards: EN1127-1:1997; EN13463-1:2001; EN13463-5:2003, and are supplied complete with the relevant ATEX approval documentation.

Yale (Columbus McKinnon) offer three levels of protection - BASIC, MEDIUM, and HIGH.

Under directive 94/9/EC, equipment for areas with an explosion hazard are assigned to groups, categories and temperature classes. This is necessary as the requirements for equipment need not be the same for every application and for every hazard classification.

NB: It is the responsibility of the end user to identify the explosion proof classification required, NOT the hoist manufacturer or the supplier. Reference Directive 99/92/EC.

|

MEDIUM (Zone 1/21 & 2/22) ATEX II 2 G Ex h IIB T4ATEX II 2 D Ex h IIIB T135°C Db |

HIGH (Zone 1/21 & 2/22) ATEX II 2 G Ex h IIC T4 GbATEX II 2 D Ex h IIIC T135°C Db |

|

|

Why explosion protection?

Explosion protection for electrical and mechanical machinery is an important precautionary measure to ensure the safety of persons and all kinds of production, storage and distribution systems, when explosive mixtures of combustible gases, dusts and air may occur.

What does explosion protection achieve?

Explosion protection can mean to generally prevent the ignition of an explosive mixture. Explosion protection can also be achieved by eliminating potential ignition sources in advance, e.g. high temperatures and sparking. In many trades and industries, combustible gases, vapours and dusts are handled which have the potential to cause explosions.

Examples of explosion hazards in various industries

- Chemical industry

- Waste disposal sites

- Energy production companies

- Waste management companies

- Gas suppliers

- Metal processing companies

- Wood-processing companies

- Paint shops

- Agriculture

- Food and feed-stuffs industry

- Pharmaceutical industry

- Refineries

- Recycling companies

Yalelift ITP Integral Push Trolley Hoists - ATEX. Capacities 0.5t to 2.0t

| Model | YLIT ATEX 500 | YLIT ATEX 1000 | YLIT ATEX 2000 |

| A min. (mm) | 245 | 272 | 323 |

| A1 (mm) | 158 | 178 | 205.5 |

| A2 (mm) | – | – | – |

| B (mm) | 17 | 22 | 30 |

| C (mm) | 24 | 29 | 35 |

| D (mm) | 14 | 19 | 22 |

| F (Geared trolley) (mm) | 92 | 92 | 91 |

| H1 (mm) | 24.5 | 24 | 23.5 |

| I (Push trolley) (mm) | 71.5 | 71.5 | 95.5 |

| I (Geared trolley) (mm) | 76.5 | 76.5 | 98 |

| L (mm) | 270 | 310 | 360 |

| L1 (mm) | 130 | 130 | 150 |

| L2 (mm) | 159 | 175 | 207 |

| M (mm) | M 18 | M 22 | M 27 |

| O (mm) | 60 | 60 | 80 |

| P (Geared trolley) (mm) | 108 | 110 | 112 |

| T (Area A) (mm) | 280 | 290 | 305 |

| T (Area B) (mm) | 400 | 410 | 425 |

| No. of Chain Falls | 1 | 1 | 1 |

| Beam Flange Thickness Max. (mm) | 19 | 19 | 19 |

| Curve Radius Min. (m) | 0.9 | 0.9 | 1.15 |

| Weight @ 3m HOL (kg) - Type 'A' Trolley | 20 | 27 | 44 |

Products of Possible Interest

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.