-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Soft Lifting Slings

- Lifting Chain Slings

- Wire Rope Slings & Assemblies

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Beam Trolleys and Crane Bridges, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

-

Confined Space and Rescue Systems

- Xtirpa Confined Space Davit Arm Systems and Components

- Sala Advanced Davit Arm Systems and Components

- Genesi Confined Space Systems

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding Hoists & Rescue Winches

- Fall Arrest & Rescue Tripods

- Fall Arrest Davit Arms & Posts for Working at Height

-

Fall Arrest & Man-riding Systems

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

- Home/

- Lifting Equipment/

- Wire Rope Pulling Winches & Lifting Hoists/

- Electric Winches and Hoists, AC (Mains Powered)/

- Yale Electric Wire Rope Winches / Hoists/

- Yale Mtrac Endless Winch - 66kg to 500kg options (two-fall design up to 1000kg)

Yale Mtrac Endless Winch - 66kg to 500kg options (two-fall design up to 1000kg)

Because the rope of the endless winch is not collected during operation, there is no limit to the lifting height and traction length.

Mtrac / YMEW-5465

The Yale Mtrac® endless winch combines state-of-the-art industrial design with technical innovation to solve a specific customer need – the need for a safe and simple handling solution for mobile applications. Yale did just that. Because the rope of the endless winch is not collected during operation, there is no limit to the lifting height and traction length when using this product. And, with a full offering of wire ropes and accessories, this winch can be used in virtually any application requiring a hoist., e.g. on construction sites, in maintenance and assembly, in wind mills and power supply, water and utility sector, overhead line maintenance, etc.

Standard Mtrac Features

- Control pendant (IP 65-type of enclosure) is connected via a control cable (2.3m as standard - other available on request).

- Standard power cable has a length of 1.0 m (longer available on request) and is fitted with a CE connector plug (or a Schuko-plug).

- 42 V low-voltage control

- Ergonomic, fitted carrying handle features a comfortable plastic grip.

- Mounting feet fixed on the housing for easy set up.

- Standard operating voltages of 400 V, 3-ph, 50 Hz or 230 V, 1-ph, 50 Hz.

- Galvanized, high-density steel rope is 10 m long (dia. 6.5 mm) and features a safety hook on one end as well as a rounded, plastic-coated tip at the loose end. Other lengths available on request.

- Two spring buffers with adjusting rings can be attached to the wire rope to set the limit switches for both upward and downward movement.

- Drive sheave is made of especially hardened steel designed to ensure long service life.

- The patented (German Patent DE 10 2012 100 099) bi-directional actuator ensures the rope is safely guided and securely held in place.

- Slip clutch is located outside of the load path for added safety.

- Limit switches ensure safe cut-out for the upper and lower hook positions.

- Electromagnetic brake holds the load safely, even in the event of a power failure.

- Winch is classified up to 1 Bm/M3 acc. to FEM/ISO.

- Winch is protected up to IP 55.

- Weight from 24 to 26kg (without rope) depending on options.

Patented* Bi-Directional Actuator

The Yale Mtrac endless winch features a unique bidirectional actuator that allows the winch to move the rated load on both ends of the rope. A hook can be fitted on the unloaded rope end (as an option) thus eliminating no-load motions. How does it work? Once the load has reached the top position, the unloaded rope end with the other hook is automatically in the bottom position and a new load can be picked up immediately. The lifting frequency is doubled as the two falls can be evenly loaded alternately with the rated load.

*German Patent DE 10 2012 100 099

Ready to Use

Each winch leaves our factory as a complete plug and play unit.

The control cable with control pendant is connected, as is the power supply cable with the plug. The standard design also features a wire rope complete with fitted safety hook. The carrying handle is included as standard and load-bearing feet are provided on the lower part of the housing.

State-of-the-art Industrial Design

A compact and state-of-the-art design was at the focus of the Yale Mtrac. The housing is made of low-pressure, die-cast aluminum and the high-strength, glass-fiber reinforced plastic covers ensure low weight and outstanding rigidity. A carrying frame, available as an option, allows for easy, two-person transport and provides additional protection against damage when moving the unit or operating it in rough conditions.

Versatile Application

Mtrac winches can be used vertically, at an angle or horizontally for versatility depending on your application.

Optionally, the load capaci ty can be doubled with two-fall reeving. Bolting points on the housing allow the customer to attach the winch in a way that best suits their application.

Proven Technology

Mtrac winches include reliable and proven Yale technology.

The oil-bath lubricated and case-hardened gearbox has a helical gearing for smooth operation and a long service life. IP 55-rated motor enclosure ensures reliable operation of the winch for both indoor and outdoor applications.

Best-in-class Safety

Standard winch models feature 42 V low-voltage control with built-in limit switches designed to stop the hoist when the hook has reached the upper or lower position. The operator can define the limit switch positions by simply relocating the spring buffers on the rope. The winch is also protected against overload by means of a slip clutch that is designed to guarantee a permanent connection between the load and the brake.

Simple Maintenance

Yale Mtrac winches are easy to service. Units are designed with a modular structure with all critical parts easily accessible.

Re-adjusting the slip clutch and inspecting the brake is quick and easy as well. In addition, the handle, or carrying frame, can be quickly and easily assembled and removed.

Ergonomic Design

Standard units have a comfortable plastic grip that allows for conven ient one-person transport. The optional carrying frame features a grip on each handle, making two-person transport easy. And, because of the rounded housing, operator injury is minimized.

Limit Switches and Limit Switch Actuator

The spring buffers attached to the rope trip the limit switch actuator when they contact the paddle, which in turn actuates the micro-switches that stop the hoisting motion (via the low voltage control).

Optional MTrac Features

Bi-Directional Lifting

Bi-Directional Lifting

To realize the full potential of this winch, operators can utilize the bi-directional actuator. Simply fit an additional hook at the loose rope end to take advan tage of this unique feature. Once the hook is in place, the unit can be used in bi-directional lifting mode (two-hook mode).

The actuator is mounted in the interior of the winch and ensures the rope smoothly runs in the drive sheave. It also extends the pressure surface of the rope on the drive sheave for safe friction contact. The two load falls are designed to alternately carry the rated load.

Carrying Frame

Carrying Frame

The carrying frame on the Yale Mtrac can be installed either at the top or at the bottom on the unit. It is ergonomically designed with plastic grips that ensure hand-friendly handling and carrying of the winch by two people.

The carrying frame cannot be used as a load-bearing component; it is exclusively intended to protect the housing, e.g. while working, during storage or while transporting or carrying the winch. Two carrying frames can also be used (one at the top and one at the bottom).

Connection to Trolleys

If low headroom is required, the Yale Mtrac winch can be easily converted from the standard hook connection to a trolley mount using a Yale trolley. Manual and power-driven trolleys available on request.

Two-part reeving Kit

Two-part reeving Kit

With this kit, the load capacity doubles (rope sold seperately - shown for illustration purposes only).

Optional

- Special voltages on request.

- Steel wire ropes of various lengths.

- Frequency converter for variable speed control or smooth starting.

- Operating hours counter to determine the remaining service life and number of switching operations.

- Radio remote control with extended operation range.

- Varying lengths for power and control cables.

- Stainless steel wire ropes (with shorter service life than standard).

Technical Specifications

| Model | Art.-No. | Single fall | Double fall Optional (two-part reeving kit required) | Motor | Operating voltage | ||

| Capacity (kg) | Lifting speed (m/min) | Capacity (kg) | Lifting speed (m/min) | ||||

| YMT 1-15 | 192025166 | 100 | 15 | 200 | 7.5 | 0.37 | 230 V/1 Ph/50 Hz |

| YMT 3-5 | 192025170 | 300 | 5 | 600 | 2.5 | 0.37 | 230 V/1 Ph/50 Hz |

| YMTF 0,6-30 | 192025175 | 66 | 30/7.5 | 130 | 15/3.7 | 0.37/0.09 | 400 V/3 Ph/50 Hz |

| YMT 1-30 | 192025171 | 100 | 30 | 200 | 15 | 0.55 | 400 V/3 Ph/50 Hz |

| YMTF 2-10 | 192025176 | 200 | 10/2.5 | 400 | 5/1.3 | 0.37/0.09 | 400 V/3 Ph/50 Hz |

| YMT 3-10 | 192025174 | 300 | 10 | 600 | 5 | 0.55 | 400 V/3 Ph/50 Hz |

| YMT 5-5 | 192053140 | 500 | 5 | 1000 | 2.5 | 0.55 | 400 V/3 Ph/50 Hz |

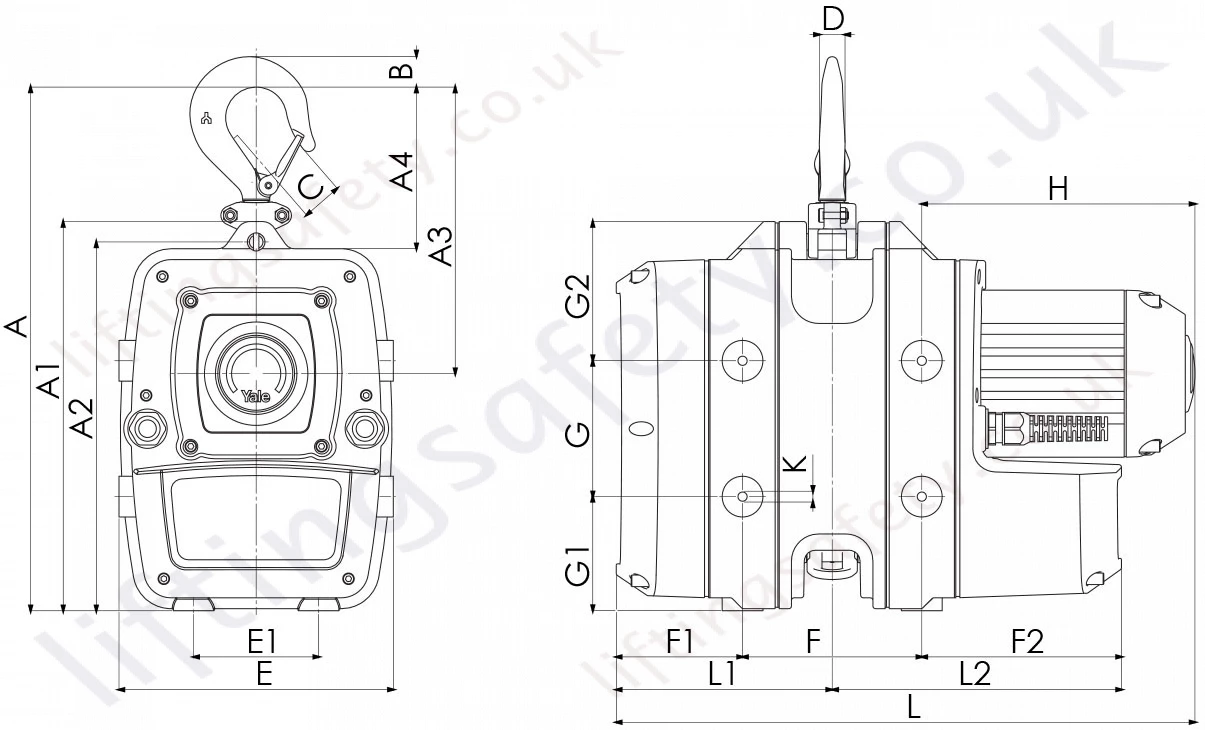

Dimensional Information

| A, mm | 385 |

| A1, mm | 287 |

| A2, mm | 272 |

| A3, mm | 221 |

| A4, mm | 119 |

| B, mm | 22 |

| C, mm | 29 |

| D, mm | 19 |

| E, mm | 202 |

| E1, mm | 92 |

| F, mm | 132 |

| F1, mm | 93 |

| F2, mm | 147 |

| G, mm | 100 |

| G1, mm | 84 |

| G2, mm | 103 |

| H, mm | 201 |

| K, mm | M8 |

| L, mm | 426 |

| L1, mm | 159 |

| L2, mm | 213 |

The Yale Mtrac® endless winch combines state-of-the-art industrial design with technical innovation to solve a specific customer need – the need for a safe and simple handling solution for mobile applications. Yale did just that. Because the rope of the endless winch is not collected during operation, there is no limit to the lifting height and traction length when using this product. And, with a full offering of wire ropes and accessories, this winch can be used in virtually any application requiring a hoist., e.g. on construction sites, in maintenance and assembly, in wind mills and power supply, water and utility sector, overhead line maintenance, etc.

Standard Mtrac Features

- Control pendant (IP 65-type of enclosure) is connected via a control cable (2.3m as standard - other available on request).

- Standard power cable has a length of 1.0 m (longer available on request) and is fitted with a CE connector plug (or a Schuko-plug).

- 42 V low-voltage control

- Ergonomic, fitted carrying handle features a comfortable plastic grip.

- Mounting feet fixed on the housing for easy set up.

- Standard operating voltages of 400 V, 3-ph, 50 Hz or 230 V, 1-ph, 50 Hz.

- Galvanized, high-density steel rope is 10 m long (dia. 6.5 mm) and features a safety hook on one end as well as a rounded, plastic-coated tip at the loose end. Other lengths available on request.

- Two spring buffers with adjusting rings can be attached to the wire rope to set the limit switches for both upward and downward movement.

- Drive sheave is made of especially hardened steel designed to ensure long service life.

- The patented (German Patent DE 10 2012 100 099) bi-directional actuator ensures the rope is safely guided and securely held in place.

- Slip clutch is located outside of the load path for added safety.

- Limit switches ensure safe cut-out for the upper and lower hook positions.

- Electromagnetic brake holds the load safely, even in the event of a power failure.

- Winch is classified up to 1 Bm/M3 acc. to FEM/ISO.

- Winch is protected up to IP 55.

- Weight from 24 to 26kg (without rope) depending on options.

Patented* Bi-Directional Actuator

The Yale Mtrac endless winch features a unique bidirectional actuator that allows the winch to move the rated load on both ends of the rope. A hook can be fitted on the unloaded rope end (as an option) thus eliminating no-load motions. How does it work? Once the load has reached the top position, the unloaded rope end with the other hook is automatically in the bottom position and a new load can be picked up immediately. The lifting frequency is doubled as the two falls can be evenly loaded alternately with the rated load.

*German Patent DE 10 2012 100 099

Ready to Use

Each winch leaves our factory as a complete plug and play unit.

The control cable with control pendant is connected, as is the power supply cable with the plug. The standard design also features a wire rope complete with fitted safety hook. The carrying handle is included as standard and load-bearing feet are provided on the lower part of the housing.

State-of-the-art Industrial Design

A compact and state-of-the-art design was at the focus of the Yale Mtrac. The housing is made of low-pressure, die-cast aluminum and the high-strength, glass-fiber reinforced plastic covers ensure low weight and outstanding rigidity. A carrying frame, available as an option, allows for easy, two-person transport and provides additional protection against damage when moving the unit or operating it in rough conditions.

Versatile Application

Mtrac winches can be used vertically, at an angle or horizontally for versatility depending on your application.

Optionally, the load capaci ty can be doubled with two-fall reeving. Bolting points on the housing allow the customer to attach the winch in a way that best suits their application.

Proven Technology

Mtrac winches include reliable and proven Yale technology.

The oil-bath lubricated and case-hardened gearbox has a helical gearing for smooth operation and a long service life. IP 55-rated motor enclosure ensures reliable operation of the winch for both indoor and outdoor applications.

Best-in-class Safety

Standard winch models feature 42 V low-voltage control with built-in limit switches designed to stop the hoist when the hook has reached the upper or lower position. The operator can define the limit switch positions by simply relocating the spring buffers on the rope. The winch is also protected against overload by means of a slip clutch that is designed to guarantee a permanent connection between the load and the brake.

Simple Maintenance

Yale Mtrac winches are easy to service. Units are designed with a modular structure with all critical parts easily accessible.

Re-adjusting the slip clutch and inspecting the brake is quick and easy as well. In addition, the handle, or carrying frame, can be quickly and easily assembled and removed.

Ergonomic Design

Standard units have a comfortable plastic grip that allows for conven ient one-person transport. The optional carrying frame features a grip on each handle, making two-person transport easy. And, because of the rounded housing, operator injury is minimized.

Limit Switches and Limit Switch Actuator

The spring buffers attached to the rope trip the limit switch actuator when they contact the paddle, which in turn actuates the micro-switches that stop the hoisting motion (via the low voltage control).

Optional MTrac Features

Bi-Directional Lifting

Bi-Directional Lifting

To realize the full potential of this winch, operators can utilize the bi-directional actuator. Simply fit an additional hook at the loose rope end to take advan tage of this unique feature. Once the hook is in place, the unit can be used in bi-directional lifting mode (two-hook mode).

The actuator is mounted in the interior of the winch and ensures the rope smoothly runs in the drive sheave. It also extends the pressure surface of the rope on the drive sheave for safe friction contact. The two load falls are designed to alternately carry the rated load.

Carrying Frame

Carrying Frame

The carrying frame on the Yale Mtrac can be installed either at the top or at the bottom on the unit. It is ergonomically designed with plastic grips that ensure hand-friendly handling and carrying of the winch by two people.

The carrying frame cannot be used as a load-bearing component; it is exclusively intended to protect the housing, e.g. while working, during storage or while transporting or carrying the winch. Two carrying frames can also be used (one at the top and one at the bottom).

Connection to Trolleys

If low headroom is required, the Yale Mtrac winch can be easily converted from the standard hook connection to a trolley mount using a Yale trolley. Manual and power-driven trolleys available on request.

Two-part reeving Kit

Two-part reeving Kit

With this kit, the load capacity doubles (rope sold seperately - shown for illustration purposes only).

Optional

- Special voltages on request.

- Steel wire ropes of various lengths.

- Frequency converter for variable speed control or smooth starting.

- Operating hours counter to determine the remaining service life and number of switching operations.

- Radio remote control with extended operation range.

- Varying lengths for power and control cables.

- Stainless steel wire ropes (with shorter service life than standard).

Technical Specifications

| Model | Art.-No. | Single fall | Double fall Optional (two-part reeving kit required) | Motor | Operating voltage | ||

| Capacity (kg) | Lifting speed (m/min) | Capacity (kg) | Lifting speed (m/min) | ||||

| YMT 1-15 | 192025166 | 100 | 15 | 200 | 7.5 | 0.37 | 230 V/1 Ph/50 Hz |

| YMT 3-5 | 192025170 | 300 | 5 | 600 | 2.5 | 0.37 | 230 V/1 Ph/50 Hz |

| YMTF 0,6-30 | 192025175 | 66 | 30/7.5 | 130 | 15/3.7 | 0.37/0.09 | 400 V/3 Ph/50 Hz |

| YMT 1-30 | 192025171 | 100 | 30 | 200 | 15 | 0.55 | 400 V/3 Ph/50 Hz |

| YMTF 2-10 | 192025176 | 200 | 10/2.5 | 400 | 5/1.3 | 0.37/0.09 | 400 V/3 Ph/50 Hz |

| YMT 3-10 | 192025174 | 300 | 10 | 600 | 5 | 0.55 | 400 V/3 Ph/50 Hz |

| YMT 5-5 | 192053140 | 500 | 5 | 1000 | 2.5 | 0.55 | 400 V/3 Ph/50 Hz |

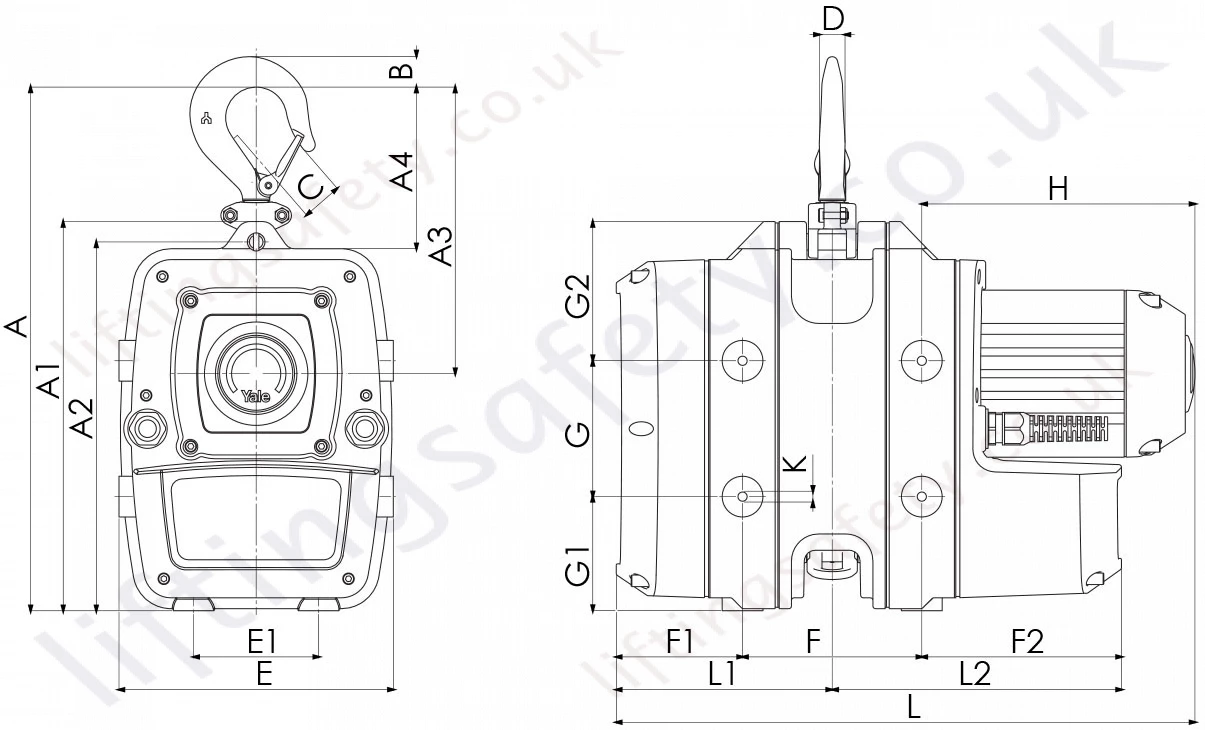

Dimensional Information

| A, mm | 385 |

| A1, mm | 287 |

| A2, mm | 272 |

| A3, mm | 221 |

| A4, mm | 119 |

| B, mm | 22 |

| C, mm | 29 |

| D, mm | 19 |

| E, mm | 202 |

| E1, mm | 92 |

| F, mm | 132 |

| F1, mm | 93 |

| F2, mm | 147 |

| G, mm | 100 |

| G1, mm | 84 |

| G2, mm | 103 |

| H, mm | 201 |

| K, mm | M8 |

| L, mm | 426 |

| L1, mm | 159 |

| L2, mm | 213 |

You May Also Like

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.