-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Soft Lifting Slings

- Lifting Chain Slings

- Wire Rope Slings & Assemblies

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Beam Trolleys and Crane Bridges, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

-

Confined Space and Rescue Systems

- Xtirpa Confined Space Davit Arm Systems and Components

- Sala Advanced Davit Arm Systems and Components

- Genesi Confined Space Systems

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding Hoists & Rescue Winches

- Fall Arrest & Rescue Tripods

- Fall Arrest Davit Arms & Posts for Working at Height

-

Fall Arrest & Man-riding Systems

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

- Home/

- Lifting Equipment/

- Specialist Lifting Equipment/

- Atex Lifting Equipment & Atex Fall Arrest Equipment/

- ATEX Hoists - Spark Resistant and Atex Rated Chain Hoists and Trolleys/

- Atex Electric Hoists and Monorail Trolleys, Anti-Sparking & Explosion Proof/

- Stahl "SH Ex" and "AS 7 Ex" ATEX Certified Wire Rope Hoists, Range from 1000g to 160,000kg

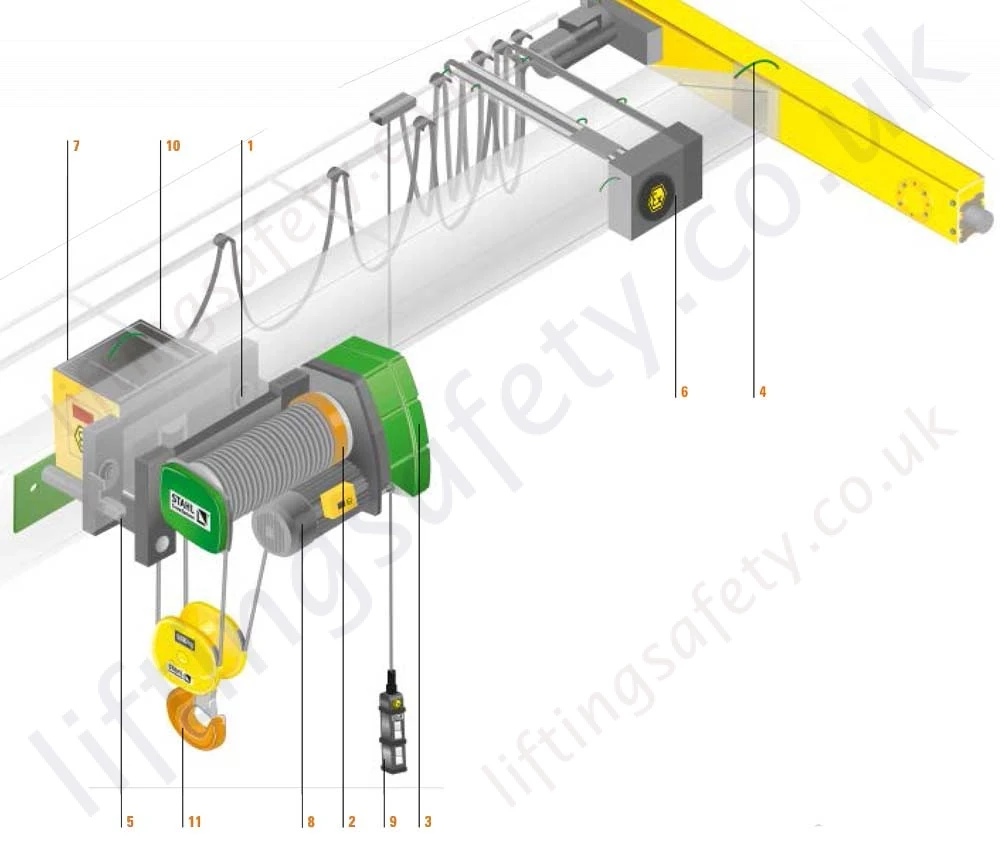

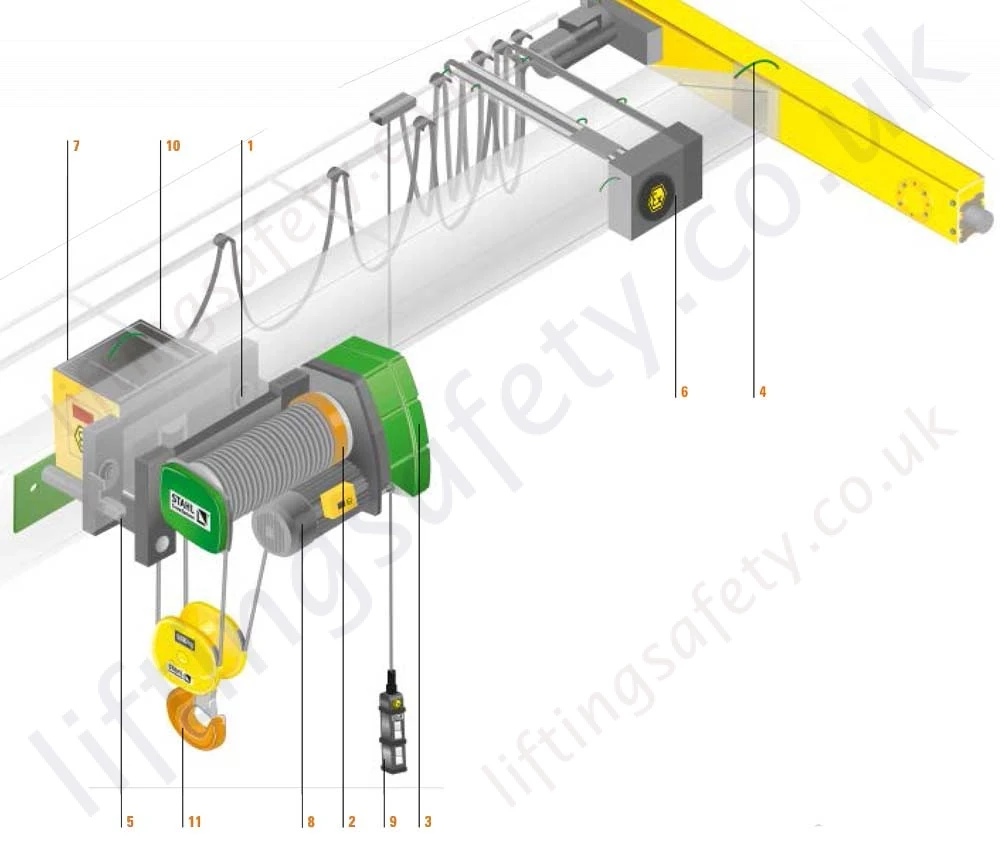

Stahl "SH Ex" and "AS 7 Ex" ATEX Certified Wire Rope Hoists, Range from 1000g to 160,000kg

Explosion Protected Wire Rope Hoists that meet the European product directive 2014/34/EU (ATEX 95) and the international IECEx regulations.

SEAE-5102

The SH Ex and AS 7 Ex explosion-protected wire rope hoists from STAHL Crane- Systems meet the European product directive 2014/34/EU (ATEX 95) and the international IECEx regulations. They are constructed for use in Zone 1 or Zone 21, however they can also be used in Zone 2 or Zone 22.

These adaptable wire rope hoists are of systematically modular construction and designed for a load capacity range of 1,000kg to 160,000kg. For the load capacity range of 1,000kg to 25,000kg the versatile SH Ex series is available in five frame sizes with 15 load capacity brackets. The upper load capacity range up to 100,000kg is covered by the field-proven AS 7 Ex and AS7 Ex ZW series.

The attractive design of STAHL CraneSystems’ wire rope hoists conceals a compact, robust construction which is largely low-maintenance. They are extremely reliable and have a longer-than-average service life. Common to all of them is the particularly smooth precise starting and braking characteristic.

The SHW Ex winch programme is available on request for the high-load bracket up to 160,000kg.

- Condition monitoring apparatus in explosion-protected design ensures safe operation.

- Electronic motor and brake management guarantees a long service life.

- Most comprehensive explosion protected wire rope hoist programme for the load capacity range from 500kg to 160,000kg.

- Equipped as standard with two hoisting and two travelling speeds.

- High standard classification in accordance with ISO.

Standard classifications in accordance with ISO

| Load Capacity (kg) | |||||||||||||||||||

| Type | Reeving | 1000 | 1250 | 1600 | 2000 | 2500 | 3200 | 4000 | 5000 | 6300 | 8000 | 10,000 | 12,500 | 16,000 | 20,000 | 25,000 | 32,000 | 40,000 | 50,000 |

| SH3 | 2/1, 4/2 | 3m | 2m | 2m | |||||||||||||||

| 4/1 | 3m | 2m | 2m | ||||||||||||||||

| SH4 | 2/1, 4/2 | 3m | 2m | 2m | 1Am | ||||||||||||||

| 4/1 | 3m | 2m | 2m | 1Am | |||||||||||||||

| SH5 | 2/1, 4/2 | 3m** | 2m | 2m | 1Am | ||||||||||||||

| 4/1 | 3m | 2m | 2m | 1Am | |||||||||||||||

| SHR6 | 2/1 | 2m | 2m | 1Am | |||||||||||||||

| 4/1 | 2m | 2m | 1Am | ||||||||||||||||

| SH6 | 2/1 | 3m | 2m | 1Am | |||||||||||||||

| 4/1 | 3m | 2m | 1Am | ||||||||||||||||

| 4/2 | 2m | 2m | 1Am | ||||||||||||||||

| AS 7 | 2/1 | 3m | 2m | 1Am | 1Bm* | ||||||||||||||

| 4/1 | 3m | 2m | 1Am | 1Bm* | |||||||||||||||

* for Zone 2, 22 only ** with 2/1 reeving, for Zone 1, 21 only

Explosion Protection

| Use | Category | Protection Against | Explosion protection class |

| Zone 1 | Ex II 2 G | Gas | Ex de eb IIB T4 Gb or Ex de eb IIC T4 Gb |

| Zone 2 | Ex II 3 G | Gas | Ex de eb nA IIB T3 (T4) Gc or Ex de eb nA IIC T3 (T4) Gc |

| Zone 21 | Ex II 2 D | Dust | Ex tb IIIC T 120 °C Db |

| Zone 22 | Ex II 3 D | Dust | Ex tc IIIC T 120 °C Dc |

Stahl: Experts in Explosion Protection

As one of the leading manufacturers of explosion-proof lifting and crane technology, STAHL CraneSystems offers a broad and complete portfolio of products as well as comprehensive services in this field. Explosion-protected products from STAHL CraneSystems meet not only German national laws and European ATEX directives but also international standards and laws for the American and Asian market. For example, all products are certified both to ATEX and IECEx.

Stahl product types are certified after passing an EC prototype test and undergo the conformity assessment procedure specified in the directives. Development and manufacture of the series products are subject to our strict quality management monitored by independent European inspection authorities. The test certificates from the notified European inspection authorities are recognised throughout the EU.

The rating plates indicate in addition to the usual data (manufacturer, type, serial number, electrical data) the data relevant to explosion protection. CE marking of the products, declaration of conformity in writing and detailed operating instructions and documentation confirm that all valid EU directives applicable to the apparatus are observed.

Decades of experience in the field of explosion protection, responsible, expert staff and production in accordance with the latest directives and standards guarantee quality down to the last detail for every piece of

explosion-protected equipment from STAHL CraneSystems.

The components and electrics, which also meet the European product directive 2014/34/EU (ATEX 95) and the international IECEx regulations, are the perfect complement to explosion-protected lifting technology from STAHL CraneSystems.

The correct functioning and high performance of a crane system depend on the quality of all its components. These are developed down to the last detail by STAHL CraneSystems and supplied from our own production. Forward-looking, high-quality modules complement one another in the system and ensure both safety and cost-effectiveness. Using the modular components, our crane manufacturing partners in your region are able to adapt the crane system individually to customer-specific requirements and wishes. Mature, cost-effective electronics, drive technology to meet the highest demands, innovative modules and field-proven, robust standard components are available for these adaptations. The expert crane manufacturing partners and experienced system manufacturers are trained by STAHL CraneSystems’ explosion protection experts so that they are always up to date as regards the status of national and international regulations and state-of-the-art technology.

Bottom Hook Block

For high and very high travelling speeds the load hook and the solid parts of potential impact surfaces are bronze-coated. In addition, all other exterior surfaces of the bottom hook block can be bronze coated to prevent sparking.

Panel Box

Flameproof enclosure for Zone 1 and Zone 2: the sheet steel or aluminium housings can be used as individual housings or in combination. All components required such as transformers, contactors, fuses, measuring instruments and tripping devices can be installed in the modular-design housing. Post-type bushings provide the connection

to the terminal box (in increased safety Ex e).

Travel Drive

The explosion-protected travel drives Zone 1 and Zone 21 are designed for intermittent operation. They have a sliding rotor motor with conical brake and centrifugal mass for smooth starting and braking characteristics. All motors are pole-changing providing two travel speeds. The particularly quiet gear requires little maintenance thanks to its long-term oil bath lubrication.

Crane End Carriages

Crane systems up to a safe working load of 50,000 kg and a span of 30 m can be built with explosion-protected end carriages for underhung and overhead travelling cranes. For particular applications, at customers’ request and for increased safety all wheels can be supplied in brass.

Control Pendants

The SWH 5 Ex control pendants are designed specifically for controlling hoists and cranes in hazardous areas. Activation is generally 2-step and permits a quick changeover from ›fast‹ to ›slow‹ and vice versa. All control pendants are equipped with an EMERGENCY STOP slam button meeting the requirements of IEC/EN 60947-5-5.

Explosion Protected End Carriages

- for single girder overhead travelling cranes, 7 wheel diameters and 5 wheel bases.

- for double girder overhead travelling cranes, 7 wheel diameters and 6 wheel bases.

- for single girder underhung cranes, 4 wheel diameters and 3 wheel bases

Explosion Protected Drive Technology

- Supplied as standard with 2-step speeds 20/5 m/min or 40/10 m/min, other speeds on request.

- As an option, stepless speed control.

Explosion Protected Control Technology

- SWH 5 Ex wired control pendant.

- Panel box in explosion-protected design.

Explosion Protected Electrics

- Festoon cables in conjunction with control pendants or radio remote controls

In lifting, drive and control technology both electrical and non-electrical components and parts can trigger an explosion. STAHL CraneSystems therefore offers apparatus specially designed for use in areas subject to gas or dust explosion hazard. All hoists and crane components without exception are from Stahl's own production, from motor and brake to controls and switchgear, and meet the latest European (ATEX) and international (IECEx) construction and safety regulations for potentially explosive atmospheres.

|

|

|

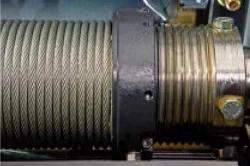

| 1. Wheels: The type of protection of all wheels is constructional safety ›c‹. If travel speeds are high, this also includes brass wheels. | 2. Rope guide / Chain Guide: The wear-resistant rope guide in nodular graphite casting GJS (previously designated GGG) is extremely durable and not subject to temperature limitations. The same applies to the chain guide, type of protection used: constructional safety. | 3. Gear: The types of protection of the gear are constructional safety ›c‹ and liquid immersion. The protective liquid (oil) prevents sparks. |

|

|

|

| 4. Euipotential Bonding: Equipotential bonding is essential for avoiding incendive sparks when installing crane technology in potentially explosive atmospheres. | 5. Overload Cut Off: The overload cut-off operates with a dual channel load sensor supplying analog signals. Various sensors are used depending on reeving (LCD, LSD). | 6. Panel Box: The type of protection for panel boxes for Zone 1, 2 and 21 on cranes and hoists combines types of protection flameproof enclosure, increased safety and protection by housing. |

|

|

|

| 7. Cable Entry: Indirect cable entry, very high safety level from type of protection increased safety and flameproof enclosure. Connection of the Ex e connection box to Ex d by post-type bushing. | 8. Motors: Motors for Zone 1 and 21 are made of grey cast iron, the type of protection combines flameproof enclosure, increased safety, and protection by housing. For Zone 2 the motors are made of aluminium and in type of protection non-sparking equipment. For Zone 22 the motors are manufactured in IP 66 and protection by housing. | 9. Control Pendant: The two-step SWH Ex control pendants in IP 66 protection are used on explosion protected wire rope hoists for Zone 1. |

|

|

|

| 10. Gear Limit Switch: The protection class of the gear limit switch is IP 66. The elements installed are protected by flameproof enclosure, the housing by increased safety. | 11. Bottom Hook Block: The type of protection employed is constructional safety, no aluminium is used. If travel speeds are high, individual parts, such as the load hook, are bronze coated. |

Pricing

The SH Ex and AS 7 Ex explosion-protected wire rope hoists from STAHL Crane- Systems meet the European product directive 2014/34/EU (ATEX 95) and the international IECEx regulations. They are constructed for use in Zone 1 or Zone 21, however they can also be used in Zone 2 or Zone 22.

These adaptable wire rope hoists are of systematically modular construction and designed for a load capacity range of 1,000kg to 160,000kg. For the load capacity range of 1,000kg to 25,000kg the versatile SH Ex series is available in five frame sizes with 15 load capacity brackets. The upper load capacity range up to 100,000kg is covered by the field-proven AS 7 Ex and AS7 Ex ZW series.

The attractive design of STAHL CraneSystems’ wire rope hoists conceals a compact, robust construction which is largely low-maintenance. They are extremely reliable and have a longer-than-average service life. Common to all of them is the particularly smooth precise starting and braking characteristic.

The SHW Ex winch programme is available on request for the high-load bracket up to 160,000kg.

- Condition monitoring apparatus in explosion-protected design ensures safe operation.

- Electronic motor and brake management guarantees a long service life.

- Most comprehensive explosion protected wire rope hoist programme for the load capacity range from 500kg to 160,000kg.

- Equipped as standard with two hoisting and two travelling speeds.

- High standard classification in accordance with ISO.

Standard classifications in accordance with ISO

| Load Capacity (kg) | |||||||||||||||||||

| Type | Reeving | 1000 | 1250 | 1600 | 2000 | 2500 | 3200 | 4000 | 5000 | 6300 | 8000 | 10,000 | 12,500 | 16,000 | 20,000 | 25,000 | 32,000 | 40,000 | 50,000 |

| SH3 | 2/1, 4/2 | 3m | 2m | 2m | |||||||||||||||

| 4/1 | 3m | 2m | 2m | ||||||||||||||||

| SH4 | 2/1, 4/2 | 3m | 2m | 2m | 1Am | ||||||||||||||

| 4/1 | 3m | 2m | 2m | 1Am | |||||||||||||||

| SH5 | 2/1, 4/2 | 3m** | 2m | 2m | 1Am | ||||||||||||||

| 4/1 | 3m | 2m | 2m | 1Am | |||||||||||||||

| SHR6 | 2/1 | 2m | 2m | 1Am | |||||||||||||||

| 4/1 | 2m | 2m | 1Am | ||||||||||||||||

| SH6 | 2/1 | 3m | 2m | 1Am | |||||||||||||||

| 4/1 | 3m | 2m | 1Am | ||||||||||||||||

| 4/2 | 2m | 2m | 1Am | ||||||||||||||||

| AS 7 | 2/1 | 3m | 2m | 1Am | 1Bm* | ||||||||||||||

| 4/1 | 3m | 2m | 1Am | 1Bm* | |||||||||||||||

* for Zone 2, 22 only ** with 2/1 reeving, for Zone 1, 21 only

Explosion Protection

| Use | Category | Protection Against | Explosion protection class |

| Zone 1 | Ex II 2 G | Gas | Ex de eb IIB T4 Gb or Ex de eb IIC T4 Gb |

| Zone 2 | Ex II 3 G | Gas | Ex de eb nA IIB T3 (T4) Gc or Ex de eb nA IIC T3 (T4) Gc |

| Zone 21 | Ex II 2 D | Dust | Ex tb IIIC T 120 °C Db |

| Zone 22 | Ex II 3 D | Dust | Ex tc IIIC T 120 °C Dc |

Stahl: Experts in Explosion Protection

As one of the leading manufacturers of explosion-proof lifting and crane technology, STAHL CraneSystems offers a broad and complete portfolio of products as well as comprehensive services in this field. Explosion-protected products from STAHL CraneSystems meet not only German national laws and European ATEX directives but also international standards and laws for the American and Asian market. For example, all products are certified both to ATEX and IECEx.

Stahl product types are certified after passing an EC prototype test and undergo the conformity assessment procedure specified in the directives. Development and manufacture of the series products are subject to our strict quality management monitored by independent European inspection authorities. The test certificates from the notified European inspection authorities are recognised throughout the EU.

The rating plates indicate in addition to the usual data (manufacturer, type, serial number, electrical data) the data relevant to explosion protection. CE marking of the products, declaration of conformity in writing and detailed operating instructions and documentation confirm that all valid EU directives applicable to the apparatus are observed.

Decades of experience in the field of explosion protection, responsible, expert staff and production in accordance with the latest directives and standards guarantee quality down to the last detail for every piece of

explosion-protected equipment from STAHL CraneSystems.

The components and electrics, which also meet the European product directive 2014/34/EU (ATEX 95) and the international IECEx regulations, are the perfect complement to explosion-protected lifting technology from STAHL CraneSystems.

The correct functioning and high performance of a crane system depend on the quality of all its components. These are developed down to the last detail by STAHL CraneSystems and supplied from our own production. Forward-looking, high-quality modules complement one another in the system and ensure both safety and cost-effectiveness. Using the modular components, our crane manufacturing partners in your region are able to adapt the crane system individually to customer-specific requirements and wishes. Mature, cost-effective electronics, drive technology to meet the highest demands, innovative modules and field-proven, robust standard components are available for these adaptations. The expert crane manufacturing partners and experienced system manufacturers are trained by STAHL CraneSystems’ explosion protection experts so that they are always up to date as regards the status of national and international regulations and state-of-the-art technology.

Bottom Hook Block

For high and very high travelling speeds the load hook and the solid parts of potential impact surfaces are bronze-coated. In addition, all other exterior surfaces of the bottom hook block can be bronze coated to prevent sparking.

Panel Box

Flameproof enclosure for Zone 1 and Zone 2: the sheet steel or aluminium housings can be used as individual housings or in combination. All components required such as transformers, contactors, fuses, measuring instruments and tripping devices can be installed in the modular-design housing. Post-type bushings provide the connection

to the terminal box (in increased safety Ex e).

Travel Drive

The explosion-protected travel drives Zone 1 and Zone 21 are designed for intermittent operation. They have a sliding rotor motor with conical brake and centrifugal mass for smooth starting and braking characteristics. All motors are pole-changing providing two travel speeds. The particularly quiet gear requires little maintenance thanks to its long-term oil bath lubrication.

Crane End Carriages

Crane systems up to a safe working load of 50,000 kg and a span of 30 m can be built with explosion-protected end carriages for underhung and overhead travelling cranes. For particular applications, at customers’ request and for increased safety all wheels can be supplied in brass.

Control Pendants

The SWH 5 Ex control pendants are designed specifically for controlling hoists and cranes in hazardous areas. Activation is generally 2-step and permits a quick changeover from ›fast‹ to ›slow‹ and vice versa. All control pendants are equipped with an EMERGENCY STOP slam button meeting the requirements of IEC/EN 60947-5-5.

Explosion Protected End Carriages

- for single girder overhead travelling cranes, 7 wheel diameters and 5 wheel bases.

- for double girder overhead travelling cranes, 7 wheel diameters and 6 wheel bases.

- for single girder underhung cranes, 4 wheel diameters and 3 wheel bases

Explosion Protected Drive Technology

- Supplied as standard with 2-step speeds 20/5 m/min or 40/10 m/min, other speeds on request.

- As an option, stepless speed control.

Explosion Protected Control Technology

- SWH 5 Ex wired control pendant.

- Panel box in explosion-protected design.

Explosion Protected Electrics

- Festoon cables in conjunction with control pendants or radio remote controls

In lifting, drive and control technology both electrical and non-electrical components and parts can trigger an explosion. STAHL CraneSystems therefore offers apparatus specially designed for use in areas subject to gas or dust explosion hazard. All hoists and crane components without exception are from Stahl's own production, from motor and brake to controls and switchgear, and meet the latest European (ATEX) and international (IECEx) construction and safety regulations for potentially explosive atmospheres.

|

|

|

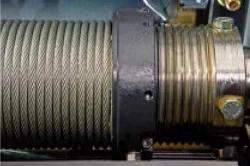

| 1. Wheels: The type of protection of all wheels is constructional safety ›c‹. If travel speeds are high, this also includes brass wheels. | 2. Rope guide / Chain Guide: The wear-resistant rope guide in nodular graphite casting GJS (previously designated GGG) is extremely durable and not subject to temperature limitations. The same applies to the chain guide, type of protection used: constructional safety. | 3. Gear: The types of protection of the gear are constructional safety ›c‹ and liquid immersion. The protective liquid (oil) prevents sparks. |

|

|

|

| 4. Euipotential Bonding: Equipotential bonding is essential for avoiding incendive sparks when installing crane technology in potentially explosive atmospheres. | 5. Overload Cut Off: The overload cut-off operates with a dual channel load sensor supplying analog signals. Various sensors are used depending on reeving (LCD, LSD). | 6. Panel Box: The type of protection for panel boxes for Zone 1, 2 and 21 on cranes and hoists combines types of protection flameproof enclosure, increased safety and protection by housing. |

|

|

|

| 7. Cable Entry: Indirect cable entry, very high safety level from type of protection increased safety and flameproof enclosure. Connection of the Ex e connection box to Ex d by post-type bushing. | 8. Motors: Motors for Zone 1 and 21 are made of grey cast iron, the type of protection combines flameproof enclosure, increased safety, and protection by housing. For Zone 2 the motors are made of aluminium and in type of protection non-sparking equipment. For Zone 22 the motors are manufactured in IP 66 and protection by housing. | 9. Control Pendant: The two-step SWH Ex control pendants in IP 66 protection are used on explosion protected wire rope hoists for Zone 1. |

|

|

|

| 10. Gear Limit Switch: The protection class of the gear limit switch is IP 66. The elements installed are protected by flameproof enclosure, the housing by increased safety. | 11. Bottom Hook Block: The type of protection employed is constructional safety, no aluminium is used. If travel speeds are high, individual parts, such as the load hook, are bronze coated. |

You May Also Like

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.