-

Lifting Equipment

Lifting Equipment

- Chain Hoists

-

Wire Rope Hoists & Winches

- Hand Operated Wire Rope Winches and Hoists

- Cable Pullers / Hoists, Wire Rope Manual Operation

- Electric Winches and Hoists, AC (Mains Powered)

- Scaffold Hoists & Accessories

- Overhead Wire Rope Crane Hoists

- Hydraulic Wire Rope Winches & Hoists

- Pneumatic Wire Rope Air Winches / Hoists (Lifting and Pulling)

- Vehicle Mounted Winches

- Tractel Wire Rope & Accessories

-

General Lifting Equipment

- Soft Lifting Slings

- Lifting Chain Slings

- Wire Rope Slings & Assemblies

- Lifting Shackles

- Eye Bolts and Nuts

- Weld-on Lifting Eyes and Lashing Points

- Lifting & Pulling Clamps

- Lifting Beams & Spreader Beams

- Precast Concrete Lifting

- Lifting Magnets, Permanent, Battery Electric and Manual

- Beam Trolleys and Crane Bridges, Push, Geared & Electric

- Equipment Identification Tags

-

Rigging Equipment

- Master Ring & Load Suspension Eyes

- Lifting & Rigging Hooks

- Turnbuckles & Rigging Screws

- Wire Rope Accessories and Fittings

- Snatch Blocks, Sheave Blocks and Crane Pulley Blocks

- Pulley Sheaves

- Lifting & Rigging Swivels - Eye, Hook & Shackle

- Load Restraint Equipment

- General Rigging Accessories

- Crosby Lifting & Rigging

-

Cranes & Gantry Systems

- Portable Davit Arms

- Swing Jib Cranes - Installed Floor & Wall Cranes

- Portable/Mobile Free-standing Swing Jib Cranes

- Aluminium Gantry Cranes

- Steel Gantry Cranes

- Fixed Steel Gantry Systems

- Shearlegs, Tripods & Quadpods

- Overhead Crane Systems

- Portable Shop-Floor/Workshop/Garage Cranes

- Counterbalance Floor, Workshop Cranes

- Scaffolding Runway Beam Systems

-

Material Handling & Jacking Equipment

- Machinery & Load Moving Skates

- Hydraulic Cylinders & Pumps

- Lifting Jacks

- Manhole Cover Lifters

- Hydraulic Pull Cylinders

- Hand Operated Pallet Trucks, Pump Trucks

- Stacker Trucks, Materials Lifts, Manual and Electric

- Genie and Counterbalance Materials Lifters

- Scissor Lift Tables

- Drum Handling Equipment

- Crane Forks

- Load Weighing Equipment - Load Cells

- Tool Spring Balancers / Load Balancers

- Platform Trucks & Trolleys

-

Forklift Truck Attachment

- Fork Mounted Man Riding Baskets

- Environment & Waste Handling Attachments

- Fork Lift Truck Mounted Drum Handling Attachments

- Fork Mounted Jib and Hook Attachments

- Fork Truck Booms & Tines

- Stainless Steel Forklift Attachments

- Forklift Truck Fork Extensions

- Multi Fork Attachments

- Fork Truck Scoop Attachments

- Big Bag Fork Truck Attachment

- Closed Base Coil Support Attachments

- Forklift Fork Protection Sleeves

- Snow Plough Fork Lift Truck Attachments

- Other Forklift Truck & Telehandler Attachments

- Specialist Lifting Equipment

- Access and Safety Related

- Workshop and Shop Floor

- Screwjacks & Actuators

-

Height Safety

Height Safety Equipment

-

Fall Arrest and Height Safety Harnesses

- General Use Harnesses EN361

- Work Positioning Harnesses EN361 & EN358

- Rope Access Harnesses

- Rescue Harnesses EN1497 & EN361

- Ladies & Childrens Harnesses

- Hi Vis Jacket/Vest Harnesses

- Welders Harnesses

- ATEX (Anti-Static) Harnesses

- Linesman Harnesses

- Oil Derrick Harnesses

- Sport Climbing Harnesses

- Tree Surgeon Positioning Harnesses

- Sit and Chest Harnesses. EN361 EN356 & EN831

- Work Positioning & Restraint Belts EN358

- Fall Arrest, Restraint and Positioning Lanyards

- Height Safety and Fall Arrest Kits

- Inertia Reels and Retrieval Blocks

-

Confined Space and Rescue Systems

- Xtirpa Confined Space Davit Arm Systems and Components

- Sala Advanced Davit Arm Systems and Components

- Genesi Confined Space Systems

- Abtech Man-riding, Fall Arrest and Rescue Davits and Components

- Man-riding Hoists & Rescue Winches

- Fall Arrest & Rescue Tripods

- Fall Arrest Davit Arms & Posts for Working at Height

-

Fall Arrest & Man-riding Systems

- Manriding Systems, Baskets and Chairs

- Mobile Fall Arrest Gantries, Systems & Steps

- Rope Guided Fall Arresters (Steel & Synthetic Rope)

- Temporary Horizontal Fall Arrest Lifelines

- Vertical Fall Arrest Systems Permanently Installed

- Horizontal Fall Arrest Systems Permanently Installed

- Manriding Baskets Fork Truck and Overhead Crane

- Tank Side Entry and Vehicle Fall Arrest Systems

- Suspension Seats / Bosuns Chair Working at Height

- Collective Fall Arrest Systems

- Man-Riding Sheave Blocks

- Anchorage Devices

- Karabiners & Connectors

- Rescue, Evacuation & Rope Access

-

General Height Safety Gear

- Height Safety Accessories

- Industrial & Climbing Height Safety Helmets

- Synthetic Height Safety Rope & Anchorage Lines

- Height safety Pulley Wheels For Synthetic & Steel Wire Rope

- Black Height Safety Equipment & PPE

- Hot Work Equipment. Cutting, Grinding & Welding

- Cases, Bags, Backpacks, Holdalls. Height Safety Gear

- Telescopic Extension Pole for Height Safety Applications

- Wind Energy Height Safety Equipment

- Stainless Steel Fall Arrest Equipment

-

Fall Arrest and Height Safety Harnesses

- Home

- About Us

-

Contact

Get In Touch

- Home/

- Lifting Equipment/

- Wire Rope Pulling Winches & Lifting Hoists/

- Electric Winches and Hoists, AC (Mains Powered)/

- Tractel Electric Wire Rope Winches / Hoists/

- Tractel Tirak Mobile Lifting Hoist In Heavy Duty Frame with Cable Reeling Drum - Range from 300kg to 3000kg

Tractel Tirak Mobile Lifting Hoist In Heavy Duty Frame with Cable Reeling Drum - Range from 300kg to 3000kg

Tirak Mobile electric winch / hoist for materials. 230v, 110v and 400v Options.

Tractel Tirak Mobile / TTM-3262

The TIRAK with its compact frame is lighter, smaller and more economic than a crane or a drum winch with the same capacity and complete with a similar length of wire rope.

The unit is self-aligning, unlike a drum winch, with which it is only possible to pull in one direction. In addition, the lifting speed and the capacity of the TIRAK remain constant.

The TIRAK mobile winch is the ideal lifting and pulling device for frequently-changed operating positions on site.

Anchoring and operation of the TIRAK ® mobile unit with its special TIRAK ® wire rope is quick and versatile. Once in position it is designed to automatically turn in the direction of line pull and for the tension and rope speed to remain constant at all times.

The outstanding features of the TIRAK ® mobile winch make it a most versatile unit; it can be used like a conventional winch as well as a materials hoist.It is the ideal solution for lifting and pulling applications in the installation of lift shafts, for tensioning conveyor belts, to operate large hangar doors, to move stage settings, to pull undergroumd power lines, in building, construction and civil engineering.

The special TIRAK ® steel wire rope supplied with the TIRAK ® has been designed and manufactured to extremely fine tolerances demanded by the TRACTEL group for use with the machine.

Safety Feature

- Terminal switch for limiting the height of lift wherever desired.

- Terminal switch switches off when it is passed by the rope termination ensuring that the rope cannot accidentally pay out fully.

- Overload trip is optional..

- Emergency lowering in power failure at a controlled speed.

- Electrical system suitable for use on building sites. The motor and controls are protected class IP54.

- Easy to operate push button pendant control.

- Heavier loads can be handled using winch with snatch blocks.

- Full safety features including limit switches and release/lower facility.

Hoist Specifications

(A) Tirak® Mobile winch with 60m* free spool wire rope reeler fitted with 3m pendant control 48vThe compact frame with free wire rope reeler allows the reeling of the wire rope up to 60 m length. The frame is designed for the TIRAK powered hoist through which the wire rope passes, series X-300, X-500, X-700 and T-1000. The compact frame has the following safety features: – wire rope limit switch (code 15428 for X-300/500/700 and code 15757 for T-1000). The necessary adjustment is by moving the adjustable end-stop (clamp). – end-of-rope sensor (code 36257 for X-300, 38177 for X-500/700 and 38717 for T-1000), which stops the TIRAK as soon as the end of the wire rope reaches the switch. It therefore prevents the wire rope running completely through the TIRAK. Option: overload limit device. |

||||||

| Model | Capacity (kg) | Reeler capacity (m) | Speed m/mn | Motor kW (¹) | ø Wire rope (mm) | Weight (kg) without rope |

| X300 | 300 | 60 | 9 | 0.5 | 8.3 | 60 |

| X302 | 300 | 60 | 17 | 0.9 | 8.3 | 60 |

| X504 | 500 | 60 | 4.5 | 0.5 | 8.3 | 75 |

| X500 | 500 | 60 | 9 | 0.9 | 8.3 | 75 |

| X505 | 500 | 60 | 4.5/9 | 0.5/0.9 | 8.3 | 85 |

| X506 | 500 | 60 | 4.5/18 | 0.5/1.8 | 8.3 | 85 |

| X503 | 500 | 60 | 9/18 | 0.9/1.8 | 8.3 | 85 |

| X804 | 800 | 60 | 4.5 | 0.8 | 8.3 | 80 |

| X800 | 800 | 60 | 9 | 1.6 | 8.3 | 80 |

| X805 | 800 | 60 | 4.5/9 | 0.8/1.6 | 8.3 | 85 |

| X806 | 800 | 60 | 4.5/18 | 0.8/3.2 | 8.3 | 105 |

| X803 | 800 | 60 | 9/18 | 1.75/3.5 | 8.3 | 85 |

| X1024 | 980 | 50 | 4.5 | 0.9 | 9.5 | 85 |

| X1020 | 980 | 50 | 9 | 1.8 | 9.5 | 80 |

| X1025 | 980 | 50 | 4.5/9 | 0.9/1.8 | 9.5 | 90 |

| X1026 | 980 | 50 | 4.5/18 | 0.9/3.8 | 9.5 | 105 |

| X1023 | 980 | 50 | 9/18 | 1.9/3.8 | 9.5 | 90 |

| X3050 | 3000 | 60 | 6 | 3.8 | 14 | 200 |

| X3052 | 3000 | 60 | 12 | 7.5 | 14 | 225 |

(B) Tirak® Mobile winch with driven (powered of main motor) wire rope reeler upto 220 metres.In this type of frame, the wire rope reeler is driven by the hoist and allows the reeling of wire ropes up to 220 m. The frame is designed for TIRAK powered hoists with wire rope reeler, series X-500, X-700 and T-1000. The compact frame has the following safety devices: – wire rope limit switch. The necessary adjustment is by moving the adjustable end-stop (clamp). – end-of-rope sensor, which stops the TIRAK as soon as the end of the wire rope reaches the switch. It therefore prevents the wire rope running completely through the TIRAK. |

||||||

| Model | Capacity (kg) | Reeler capacity (m) | Speed m/mn | Motor kW (¹) | ø Wire rope (mm) | Weight (kg) without rope |

| X500 | 500 | 120 | 9 | 0.9 | 8.3 | 115 |

| X504 | 500 | 120 | 4.5 | 0.5 | 8.3 | 115 |

| X505 | 500 | 120 | 4.5/9 | 0.5/0.9 | 8.3 | 125 |

| X506 | 500 | 120 | 4.5/18 | 0.5/1.8 | 8.3 | 125 |

| X503 | 500 | 120 | 9/18 | 0.9/1.8 | 8.3 | 125 |

| X804 | 800 | 120 | 4.5 | 0.8 | 8.3 | 120 |

| X800 | 800 | 120 | 9 | 1.6 | 8.3 | 120 |

| X805 | 800 | 120 | 4.5/9 | 0.8/1.6 | 8.3 | 125 |

| X806 | 800 | 120 | 4.5/18 | 0.8/3.2 | 8.3 | 145 |

| X803 | 800 | 120 | 9/18 | 1.75/3.5 | 8.3 | 125 |

| X1024 | 980 | 95 | 4.5 | 0.9 | 9.5 | 125 |

| X1020 | 980 | 95 | 9 | 1.9 | 9.5 | 120 |

| X1025 | 980 | 95 | 4.5/9 | 0.9/1.8 | 9.5 | 130 |

| X1026 | 980 | 95 | 5.5/18 | 0.9/3.8 | 9.5 | 145 |

| X1023 | 980 | 95 | 9/18 | 1.9/3.8 | 9.5 | 130 |

(C) Tirak® Mobile winch with upto 500m (800m on X3000 series) dedicated powered wire rope reeler.The wire rope reeler is driven by the hoist (by a chain), allowing the reeling of wire ropes up to 800 m in length. The reeling is controlled by a pivoting reeling arm. The frame is designed for TIRAK powered hoists with wire rope reeler, series T-500 and T-1000. The frame is fitted with the following safety features: – wire rope limit switch. The necessary adjustment is by moving the adjustable end-stop (clamp). – an end-of-rope sensor, which stops the TIRAK as soon as the end of the wire rope reaches the switch. It therefore prevents the wire rope running completely through the TIRAK.

|

||||||

| Model | Capacity (kg) | Reeler capacity (m) | Speed m/mn | Motor kW (¹) | ø Wire rope (mm) | Weight (kg) without rope |

| X500 | 500 | 500 | 9 | 0.9 | 8.3 | 115 |

| X504 | 500 | 500 | 4.5 | 0.5 | 8.3 | 115 |

| X505 | 500 | 500 | 4.5/9 | 0.5/0.9 | 8.3 | 125 |

| X506 | 500 | 500 | 4.5/18 | 0.5/1.8 | 8.3 | 125 |

| X503 | 500 | 500 | 9/18 | 0.9/1.8 | 8.3 | 125 |

| X804 | 800 | 400 | 4.5 | 0.8 | 8.3 | 120 |

| X800 | 800 | 400 | 9 | 1.6 | 8.3 | 120 |

| X805 | 800 | 400 | 4.5/9 | 0.8/1.6 | 8.3 | 125 |

| X806 | 800 | 400 | 4.5/18 | 0.8/3.2 | 8.3 | 145 |

| X803 | 800 | 400 | 9/18 | 1.75/3.5 | 8.3 | 125 |

| X1024 | 980 | 350 | 4.5 | 0.9 | 9.5 | 125 |

| X1020 | 980 | 350 | 9 | 1.9 | 9.5 | 120 |

| X1025 | 980 | 350 | 4.5/9 | 0.9/1.8 | 9.5 | 130 |

| X1026 | 980 | 350 | 5.5/18 | 0.9/3.8 | 9.5 | 145 |

| X1023 | 980 | 350 | 9/18 | 1.9/3.8 | 9.5 | 130 |

| X3050 | 3000 | 800 | 6 | 3.8 | 14 | TBC |

| X3052 | 3000 | 800 | 12 | 7.5 | 14 | TBC |

Tirak

The TIRAK is a powered hoist through wire which the rope passes. It has the following advantages:

- Unlimited length of wire rope.

- Constant speed.

- Orientation in direction of effort.

- Mobile and compact.

- High lifting capacity: upto 3000kg.

- Safe and reliable design.

- Also available with hydraulic or pneumatic motor.

Tirak - Method of operation.

To anchor the frame.

All you need is a sling or a chain, secured to a suffiently strong fixed point.

Orientation.

Automatically aligns itself with the pull. Its capacity and speed always remain constant.

Lifting a load.

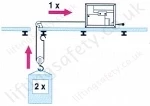

Anchor the hoist wherever you wish and divert the wire rope using one or more return pulley blocks.

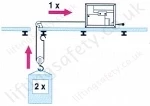

Lifting and sheave bloacks.

If the direct capacity is not adequate, increase the capacity by passing the wire round one or more sheave blocks.

Direct lifting or pulling.

Pass the wire rope through an aperture in a ceiling or a wall which is strong enough to take the load, and place the hoist against the opening.

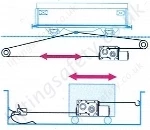

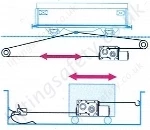

To-and-fro movement.

The hoist moves the load to and fro or moves with the load.

Applications

By Nature ...

The tirak ® is, due to its special advantages,

- minimum own weight,

- compact shape,

- unlimited rope length ...

... an ideal materials handling hoist, applicable for a wide scope of purposes.

Above all, during assembly and installation works, where mobility is of utmost importance, it pays in a minium of time.

Three variations ...

Offer a wide scope of applications using the tirak®:

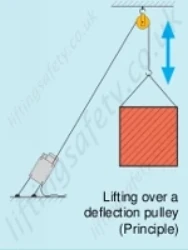

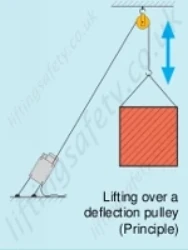

- tirak® above the load.

- tirak® anchored „within reach” – which, due to the non-restricted wire rope length, is a rather relative term. On top, only a deflection pulley has to be anchored.This facilitates any installation, saving a lot of time.

- Or, even easier and quicker: If you want to pull through an opening in a wall or ceiling capable of bearing the load: Simply site the tirak® by or above the hole! However, in this case it is recommended to use the tirak® as a “Mobile Winch”.

The “double-pull” ...

By the way, the tirak T 1000 series pulls in both directions, with full capacity!

The tirak is consequently more than a simple „wire rope hoist”, it also serves for moving ack-and fro of loads – waggon shunting, internal transport systems, or traversing of site rotection shelters – three examples, which might pave the way for a long-desired problem-solution!

Operating and Maintenance Manual

The Mobile Winch with TIRAK® Including all technical data.

(approx. 0.7Mb)Full Specification and applications.

Need to know more about the man riding Tirak? This document contains the original operating instructions which includes; safety advice, machine description, setup instructions, operation, troubleshooting and maintenance instructions.

(approx. 2.0Mb)Pricing

The TIRAK with its compact frame is lighter, smaller and more economic than a crane or a drum winch with the same capacity and complete with a similar length of wire rope.

The unit is self-aligning, unlike a drum winch, with which it is only possible to pull in one direction. In addition, the lifting speed and the capacity of the TIRAK remain constant.

The TIRAK mobile winch is the ideal lifting and pulling device for frequently-changed operating positions on site.

Anchoring and operation of the TIRAK ® mobile unit with its special TIRAK ® wire rope is quick and versatile. Once in position it is designed to automatically turn in the direction of line pull and for the tension and rope speed to remain constant at all times.

The outstanding features of the TIRAK ® mobile winch make it a most versatile unit; it can be used like a conventional winch as well as a materials hoist.It is the ideal solution for lifting and pulling applications in the installation of lift shafts, for tensioning conveyor belts, to operate large hangar doors, to move stage settings, to pull undergroumd power lines, in building, construction and civil engineering.

The special TIRAK ® steel wire rope supplied with the TIRAK ® has been designed and manufactured to extremely fine tolerances demanded by the TRACTEL group for use with the machine.

Safety Feature

- Terminal switch for limiting the height of lift wherever desired.

- Terminal switch switches off when it is passed by the rope termination ensuring that the rope cannot accidentally pay out fully.

- Overload trip is optional..

- Emergency lowering in power failure at a controlled speed.

- Electrical system suitable for use on building sites. The motor and controls are protected class IP54.

- Easy to operate push button pendant control.

- Heavier loads can be handled using winch with snatch blocks.

- Full safety features including limit switches and release/lower facility.

Hoist Specifications

(A) Tirak® Mobile winch with 60m* free spool wire rope reeler fitted with 3m pendant control 48vThe compact frame with free wire rope reeler allows the reeling of the wire rope up to 60 m length. The frame is designed for the TIRAK powered hoist through which the wire rope passes, series X-300, X-500, X-700 and T-1000. The compact frame has the following safety features: – wire rope limit switch (code 15428 for X-300/500/700 and code 15757 for T-1000). The necessary adjustment is by moving the adjustable end-stop (clamp). – end-of-rope sensor (code 36257 for X-300, 38177 for X-500/700 and 38717 for T-1000), which stops the TIRAK as soon as the end of the wire rope reaches the switch. It therefore prevents the wire rope running completely through the TIRAK. Option: overload limit device. |

||||||

| Model | Capacity (kg) | Reeler capacity (m) | Speed m/mn | Motor kW (¹) | ø Wire rope (mm) | Weight (kg) without rope |

| X300 | 300 | 60 | 9 | 0.5 | 8.3 | 60 |

| X302 | 300 | 60 | 17 | 0.9 | 8.3 | 60 |

| X504 | 500 | 60 | 4.5 | 0.5 | 8.3 | 75 |

| X500 | 500 | 60 | 9 | 0.9 | 8.3 | 75 |

| X505 | 500 | 60 | 4.5/9 | 0.5/0.9 | 8.3 | 85 |

| X506 | 500 | 60 | 4.5/18 | 0.5/1.8 | 8.3 | 85 |

| X503 | 500 | 60 | 9/18 | 0.9/1.8 | 8.3 | 85 |

| X804 | 800 | 60 | 4.5 | 0.8 | 8.3 | 80 |

| X800 | 800 | 60 | 9 | 1.6 | 8.3 | 80 |

| X805 | 800 | 60 | 4.5/9 | 0.8/1.6 | 8.3 | 85 |

| X806 | 800 | 60 | 4.5/18 | 0.8/3.2 | 8.3 | 105 |

| X803 | 800 | 60 | 9/18 | 1.75/3.5 | 8.3 | 85 |

| X1024 | 980 | 50 | 4.5 | 0.9 | 9.5 | 85 |

| X1020 | 980 | 50 | 9 | 1.8 | 9.5 | 80 |

| X1025 | 980 | 50 | 4.5/9 | 0.9/1.8 | 9.5 | 90 |

| X1026 | 980 | 50 | 4.5/18 | 0.9/3.8 | 9.5 | 105 |

| X1023 | 980 | 50 | 9/18 | 1.9/3.8 | 9.5 | 90 |

| X3050 | 3000 | 60 | 6 | 3.8 | 14 | 200 |

| X3052 | 3000 | 60 | 12 | 7.5 | 14 | 225 |

(B) Tirak® Mobile winch with driven (powered of main motor) wire rope reeler upto 220 metres.In this type of frame, the wire rope reeler is driven by the hoist and allows the reeling of wire ropes up to 220 m. The frame is designed for TIRAK powered hoists with wire rope reeler, series X-500, X-700 and T-1000. The compact frame has the following safety devices: – wire rope limit switch. The necessary adjustment is by moving the adjustable end-stop (clamp). – end-of-rope sensor, which stops the TIRAK as soon as the end of the wire rope reaches the switch. It therefore prevents the wire rope running completely through the TIRAK. |

||||||

| Model | Capacity (kg) | Reeler capacity (m) | Speed m/mn | Motor kW (¹) | ø Wire rope (mm) | Weight (kg) without rope |

| X500 | 500 | 120 | 9 | 0.9 | 8.3 | 115 |

| X504 | 500 | 120 | 4.5 | 0.5 | 8.3 | 115 |

| X505 | 500 | 120 | 4.5/9 | 0.5/0.9 | 8.3 | 125 |

| X506 | 500 | 120 | 4.5/18 | 0.5/1.8 | 8.3 | 125 |

| X503 | 500 | 120 | 9/18 | 0.9/1.8 | 8.3 | 125 |

| X804 | 800 | 120 | 4.5 | 0.8 | 8.3 | 120 |

| X800 | 800 | 120 | 9 | 1.6 | 8.3 | 120 |

| X805 | 800 | 120 | 4.5/9 | 0.8/1.6 | 8.3 | 125 |

| X806 | 800 | 120 | 4.5/18 | 0.8/3.2 | 8.3 | 145 |

| X803 | 800 | 120 | 9/18 | 1.75/3.5 | 8.3 | 125 |

| X1024 | 980 | 95 | 4.5 | 0.9 | 9.5 | 125 |

| X1020 | 980 | 95 | 9 | 1.9 | 9.5 | 120 |

| X1025 | 980 | 95 | 4.5/9 | 0.9/1.8 | 9.5 | 130 |

| X1026 | 980 | 95 | 5.5/18 | 0.9/3.8 | 9.5 | 145 |

| X1023 | 980 | 95 | 9/18 | 1.9/3.8 | 9.5 | 130 |

(C) Tirak® Mobile winch with upto 500m (800m on X3000 series) dedicated powered wire rope reeler.The wire rope reeler is driven by the hoist (by a chain), allowing the reeling of wire ropes up to 800 m in length. The reeling is controlled by a pivoting reeling arm. The frame is designed for TIRAK powered hoists with wire rope reeler, series T-500 and T-1000. The frame is fitted with the following safety features: – wire rope limit switch. The necessary adjustment is by moving the adjustable end-stop (clamp). – an end-of-rope sensor, which stops the TIRAK as soon as the end of the wire rope reaches the switch. It therefore prevents the wire rope running completely through the TIRAK.

|

||||||

| Model | Capacity (kg) | Reeler capacity (m) | Speed m/mn | Motor kW (¹) | ø Wire rope (mm) | Weight (kg) without rope |

| X500 | 500 | 500 | 9 | 0.9 | 8.3 | 115 |

| X504 | 500 | 500 | 4.5 | 0.5 | 8.3 | 115 |

| X505 | 500 | 500 | 4.5/9 | 0.5/0.9 | 8.3 | 125 |

| X506 | 500 | 500 | 4.5/18 | 0.5/1.8 | 8.3 | 125 |

| X503 | 500 | 500 | 9/18 | 0.9/1.8 | 8.3 | 125 |

| X804 | 800 | 400 | 4.5 | 0.8 | 8.3 | 120 |

| X800 | 800 | 400 | 9 | 1.6 | 8.3 | 120 |

| X805 | 800 | 400 | 4.5/9 | 0.8/1.6 | 8.3 | 125 |

| X806 | 800 | 400 | 4.5/18 | 0.8/3.2 | 8.3 | 145 |

| X803 | 800 | 400 | 9/18 | 1.75/3.5 | 8.3 | 125 |

| X1024 | 980 | 350 | 4.5 | 0.9 | 9.5 | 125 |

| X1020 | 980 | 350 | 9 | 1.9 | 9.5 | 120 |

| X1025 | 980 | 350 | 4.5/9 | 0.9/1.8 | 9.5 | 130 |

| X1026 | 980 | 350 | 5.5/18 | 0.9/3.8 | 9.5 | 145 |

| X1023 | 980 | 350 | 9/18 | 1.9/3.8 | 9.5 | 130 |

| X3050 | 3000 | 800 | 6 | 3.8 | 14 | TBC |

| X3052 | 3000 | 800 | 12 | 7.5 | 14 | TBC |

Tirak

The TIRAK is a powered hoist through wire which the rope passes. It has the following advantages:

- Unlimited length of wire rope.

- Constant speed.

- Orientation in direction of effort.

- Mobile and compact.

- High lifting capacity: upto 3000kg.

- Safe and reliable design.

- Also available with hydraulic or pneumatic motor.

Tirak - Method of operation.

To anchor the frame.

All you need is a sling or a chain, secured to a suffiently strong fixed point.

Orientation.

Automatically aligns itself with the pull. Its capacity and speed always remain constant.

Lifting a load.

Anchor the hoist wherever you wish and divert the wire rope using one or more return pulley blocks.

Lifting and sheave bloacks.

If the direct capacity is not adequate, increase the capacity by passing the wire round one or more sheave blocks.

Direct lifting or pulling.

Pass the wire rope through an aperture in a ceiling or a wall which is strong enough to take the load, and place the hoist against the opening.

To-and-fro movement.

The hoist moves the load to and fro or moves with the load.

Applications

By Nature ...

The tirak ® is, due to its special advantages,

- minimum own weight,

- compact shape,

- unlimited rope length ...

... an ideal materials handling hoist, applicable for a wide scope of purposes.

Above all, during assembly and installation works, where mobility is of utmost importance, it pays in a minium of time.

Three variations ...

Offer a wide scope of applications using the tirak®:

- tirak® above the load.

- tirak® anchored „within reach” – which, due to the non-restricted wire rope length, is a rather relative term. On top, only a deflection pulley has to be anchored.This facilitates any installation, saving a lot of time.

- Or, even easier and quicker: If you want to pull through an opening in a wall or ceiling capable of bearing the load: Simply site the tirak® by or above the hole! However, in this case it is recommended to use the tirak® as a “Mobile Winch”.

The “double-pull” ...

By the way, the tirak T 1000 series pulls in both directions, with full capacity!

The tirak is consequently more than a simple „wire rope hoist”, it also serves for moving ack-and fro of loads – waggon shunting, internal transport systems, or traversing of site rotection shelters – three examples, which might pave the way for a long-desired problem-solution!

Operating and Maintenance Manual

The Mobile Winch with TIRAK® Including all technical data.

(approx. 0.7Mb)Full Specification and applications.

Need to know more about the man riding Tirak? This document contains the original operating instructions which includes; safety advice, machine description, setup instructions, operation, troubleshooting and maintenance instructions.

(approx. 2.0Mb)You May Also Like

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.