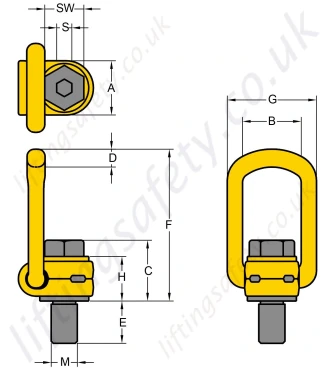

Yoke "Type 212" UNC Thread Swivel Lifting Point, Standard Length Bolt

Imperial thread swivel hoist / rotating load rings / eye bolt with pivot link. 1t to 8t, 1/2" to 1-1/2".

Model:

8-212 Series / YUTS-5237