LIFTING

SAFETY

- Lifting Equipment

-

Height Safety

Height Safety Equipment

- Material Handling & Jacking Equipment

- Shop by Brand

-

Contact

Get In Touch

sales@liftingsafety.co.uk

+44 (0)1977 684 600

sales@liftingsafety.co.uk

+44 (0)1977 684 600

- Home/

- Lifting Equipment/

- General Industrial Lifting Equipment/

- Lifting Eye Bolts & Nuts/

- Swivel Lifting Eye Bolts/

- Yoke Swivel Lifting Eyes/

- Yoke "Type 204" UNC Thread Swivel Hoist Ring with Alloy Steel Washer

Lifting Point Features

- Rotates through 360° and pivot 180°, rated at 100% at 90°angle.

- Manufactured from forged alloy steel, quenched and tempered.

- Manufactured and tested in accordance with EN1677-1.

- Load-rated parts are 100% magnaflux crack detected.

- Individual forged parts and cap screw are traceable to Test Certification.

- Bolts are UNC thread (ASME/ ANSI B18.31M).

- Proof tested to 2.5 times the WLL.

- Fatigue rated to 1.5 times the WLL.

- Design Factor 5 : 1.

- All YOKE Lifting points meet or exceed all the requirements of ASME B30.26.

- Quick and simple assembly, just a tapped hole is required.

- Longer bolts available on request.

- RFID chip fitted as standard which gives direct access to the original user instructions and Declaration of Conformity.

- Swivel Hoist Ring uses can be as follows:

- Heavy duty flexible attachment point

- Suited for lifting objects with no obvious attachment points

- Mold and die handling

- Pump and valve handling

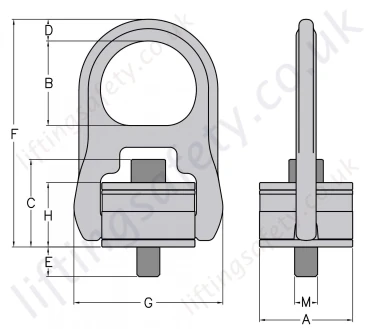

Dimensions & Specifications

| WLL (lbs) | M (inch) | Threads per inch | A (inch) | B (inch) | C (inch) | D (inch) | E (inch) | F (inch) | G (inch) | H (inch) | Torque (Ft -lbs) | Weight (lbs) |

| 800 | 5/16 | 18UNC | 1.57 | 1.61 | 1.61 | 0.35 | 0.71 | 4.02 | 2.56 | 1.29 | 7 | 0.9 |

| 1000 | 3/8 | 16UNC | 1.57 | 1.61 | 1.69 | 0.35 | 0.71 | 4.02 | 2.56 | 1.29 | 12 | 0.9 |

| 2500 | 1/2 | 13UNC | 2.56 | 2.32 | 2.24 | 0.59 | 0.75 | 6.26 | 4.13 | 1.77 | 28 | 3.7 |

| 4000 | 5/8 | 11UNC | 2.56 | 2.32 | 2.38 | 0.59 | 0.74 | 6.26 | 4.13 | 1.77 | 60 | 4 |

| 5000 | 3/4 | 10UNC | 2.56 | 2.87 | 2.51 | 0.59 | 1.24 | 6.26 | 4.13 | 1.77 | 100 | 4 |

| 8000 | 7/8 | 9UNC | 3.35 | 2.87 | 3.07 | 0.87 | 1.43 | 8.03 | 5.28 | 2.13 | 160 | 9.3 |

| 10000 | 1 | 8UNC | 3.35 | 2.87 | 3.07 | 0.87 | 1.36 | 8.03 | 5.28 | 2.13 | 230 | 9.5 |

| 15000 | 1-1/4 | 7UNC | 3.95 | 3.15 | 3.06 | 1 | 2.25 | 8.58 | 6.3 | 2.27 | 470 | 14.5 |

| 24000 | 1-1/2 | 6UNC | 4.72 | 4.29 | 4.29 | 1.38 | 2.17 | 12.09 | 8.66 | 3.36 | 800 | 35.2 |

| 30000 | 2 | 4.5UNC | 4.72 | 4.29 | 4.54 | 1.38 | 3.01 | 12.09 | 8.66 | 3.36 | 1100 | 35.2 |

Load Chart

| Number of leg | 1 | 2 | 1 | 2 | 2 | 2 | 3-4 | 3-4 | ||

| Load Direction | 0° | 0° | 90° | 90° | 0-45° | 45-60° | unsymm. | 0-45° | 45-60° | unsymm. |

| Thread | WLL tonnes | |||||||||

| 5/16" | 0.36 | 0.72 | 0.36 | 0.72 | 0.504 | 0.36 | 0.36 | 0.756 | 0.54 | 0.36 |

| 3/8" | 0.45 | 0.9 | 0.45 | 0.9 | 0.63 | 0.45 | 0.45 | 0.945 | 0.675 | 0.45 |

| 1/2" | 1.1 | 2.2 | 1.1 | 2.2 | 1.54 | 1.1 | 1.1 | 2.31 | 1.65 | 1.1 |

| 5/8" | 1.8 | 3.6 | 1.8 | 3.6 | 2.52 | 1.8 | 1.8 | 3.78 | 2.7 | 1.8 |

| 3/4" | 2.2 | 4.4 | 2.2 | 4.4 | 3.08 | 2.2 | 2.2 | 4.62 | 3.3 | 2.2 |

| 7/8" | 3.6 | 7.2 | 3.6 | 7.2 | 5.04 | 3.6 | 3.6 | 7.56 | 5.4 | 3.6 |

| 1" | 4.5 | 9 | 4.5 | 9 | 6.3 | 4.5 | 4.5 | 9.45 | 6.75 | 4.5 |

| 1-1/4" | 6.8 | 13.6 | 6.8 | 13.6 | 9.52 | 6.8 | 6.8 | 14.28 | 10.2 | 6.8 |

| 1-1/2" | 10.9 | 21.8 | 10.9 | 21.8 | 15.26 | 10.9 | 10.9 | 22.89 | 16.35 | 10.9 |

| 2" | 13.6 | 27.2 | 13.6 | 27.2 | 19.04 | 13.6 | 13.6 | 28.56 | 20.4 | 13.6 |

Lifting Point Features

- Rotates through 360° and pivot 180°, rated at 100% at 90°angle.

- Manufactured from forged alloy steel, quenched and tempered.

- Manufactured and tested in accordance with EN1677-1.

- Load-rated parts are 100% magnaflux crack detected.

- Individual forged parts and cap screw are traceable to Test Certification.

- Bolts are UNC thread (ASME/ ANSI B18.31M).

- Proof tested to 2.5 times the WLL.

- Fatigue rated to 1.5 times the WLL.

- Design Factor 5 : 1.

- All YOKE Lifting points meet or exceed all the requirements of ASME B30.26.

- Quick and simple assembly, just a tapped hole is required.

- Longer bolts available on request.

- RFID chip fitted as standard which gives direct access to the original user instructions and Declaration of Conformity.

- Swivel Hoist Ring uses can be as follows:

- Heavy duty flexible attachment point

- Suited for lifting objects with no obvious attachment points

- Mold and die handling

- Pump and valve handling

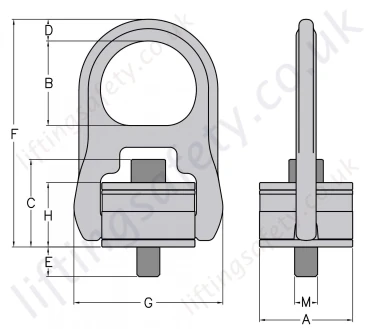

Dimensions & Specifications

| WLL (lbs) | M (inch) | Threads per inch | A (inch) | B (inch) | C (inch) | D (inch) | E (inch) | F (inch) | G (inch) | H (inch) | Torque (Ft -lbs) | Weight (lbs) |

| 800 | 5/16 | 18UNC | 1.57 | 1.61 | 1.61 | 0.35 | 0.71 | 4.02 | 2.56 | 1.29 | 7 | 0.9 |

| 1000 | 3/8 | 16UNC | 1.57 | 1.61 | 1.69 | 0.35 | 0.71 | 4.02 | 2.56 | 1.29 | 12 | 0.9 |

| 2500 | 1/2 | 13UNC | 2.56 | 2.32 | 2.24 | 0.59 | 0.75 | 6.26 | 4.13 | 1.77 | 28 | 3.7 |

| 4000 | 5/8 | 11UNC | 2.56 | 2.32 | 2.38 | 0.59 | 0.74 | 6.26 | 4.13 | 1.77 | 60 | 4 |

| 5000 | 3/4 | 10UNC | 2.56 | 2.87 | 2.51 | 0.59 | 1.24 | 6.26 | 4.13 | 1.77 | 100 | 4 |

| 8000 | 7/8 | 9UNC | 3.35 | 2.87 | 3.07 | 0.87 | 1.43 | 8.03 | 5.28 | 2.13 | 160 | 9.3 |

| 10000 | 1 | 8UNC | 3.35 | 2.87 | 3.07 | 0.87 | 1.36 | 8.03 | 5.28 | 2.13 | 230 | 9.5 |

| 15000 | 1-1/4 | 7UNC | 3.95 | 3.15 | 3.06 | 1 | 2.25 | 8.58 | 6.3 | 2.27 | 470 | 14.5 |

| 24000 | 1-1/2 | 6UNC | 4.72 | 4.29 | 4.29 | 1.38 | 2.17 | 12.09 | 8.66 | 3.36 | 800 | 35.2 |

| 30000 | 2 | 4.5UNC | 4.72 | 4.29 | 4.54 | 1.38 | 3.01 | 12.09 | 8.66 | 3.36 | 1100 | 35.2 |

Load Chart

| Number of leg | 1 | 2 | 1 | 2 | 2 | 2 | 3-4 | 3-4 | ||

| Load Direction | 0° | 0° | 90° | 90° | 0-45° | 45-60° | unsymm. | 0-45° | 45-60° | unsymm. |

| Thread | WLL tonnes | |||||||||

| 5/16" | 0.36 | 0.72 | 0.36 | 0.72 | 0.504 | 0.36 | 0.36 | 0.756 | 0.54 | 0.36 |

| 3/8" | 0.45 | 0.9 | 0.45 | 0.9 | 0.63 | 0.45 | 0.45 | 0.945 | 0.675 | 0.45 |

| 1/2" | 1.1 | 2.2 | 1.1 | 2.2 | 1.54 | 1.1 | 1.1 | 2.31 | 1.65 | 1.1 |

| 5/8" | 1.8 | 3.6 | 1.8 | 3.6 | 2.52 | 1.8 | 1.8 | 3.78 | 2.7 | 1.8 |

| 3/4" | 2.2 | 4.4 | 2.2 | 4.4 | 3.08 | 2.2 | 2.2 | 4.62 | 3.3 | 2.2 |

| 7/8" | 3.6 | 7.2 | 3.6 | 7.2 | 5.04 | 3.6 | 3.6 | 7.56 | 5.4 | 3.6 |

| 1" | 4.5 | 9 | 4.5 | 9 | 6.3 | 4.5 | 4.5 | 9.45 | 6.75 | 4.5 |

| 1-1/4" | 6.8 | 13.6 | 6.8 | 13.6 | 9.52 | 6.8 | 6.8 | 14.28 | 10.2 | 6.8 |

| 1-1/2" | 10.9 | 21.8 | 10.9 | 21.8 | 15.26 | 10.9 | 10.9 | 22.89 | 16.35 | 10.9 |

| 2" | 13.6 | 27.2 | 13.6 | 27.2 | 19.04 | 13.6 | 13.6 | 28.56 | 20.4 | 13.6 |

You May Also Like

Contact Us About This Product

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

Regarding: Yoke "Type 204" UNC Thread Swivel Hoist Ring with Alloy Steel Washer

Did you know?

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.