- Lifting Equipment

-

Height Safety

Height Safety Equipment

- Material Handling & Jacking Equipment

- Shop by Brand

- Clearance

-

Contact

Get In Touchsales@liftingsafety.co.uk +44 (0)1977 684 600

- Home/

- Lifting Equipment/

- Cranes; Mobile, Portable and Fixed/

- Counterbalance Floor, Workshop Cranes/

- Pivoting Arm Counterbalance Floor Cranes/

- MANUAL - Pivoting Arm Counterbalance Workshop Floor Crane With Hydraulic Ram Lifting, Hand Lift & Travel, Many Options

This is our most popular counterbalance workshop floor crane, and the design of this portable floor crane incorporates many key features that make it one of the most versatile items of workshop lifting equipment that we sell. We also make special versions of the crane to our customers' own specification with bespoke dimensions and lifting capacities, jib reach and height.

Note: Some pictures shown are our artists' impression only and are only indicative of our capability. (for display purposes only) All cranes are made individually, and the design may be subject to change according to your required specification; the pictures are not to scale. General arrangement drawings will be issued for approval on receipt of your order.

The most common additions to the standard cranes are:

- Removable vertical jib column to assist packing for export orders

- Vertical telescopic mast adjustment

- Brakes with locking castors and directional locking castors/wheels

- Electric power drive/propulsion and electric lift

- Outriggers on the crane body ensure a stable lift at height.

- Certified lifting points for the ability to have a crane lifted/moved by an overhead crane.

- Fork truck pockets, to enable the counterbalanced floor crane to be moved by a fork truck.

- Jacking feet to give a level and stable lift

- A rotating vertical jib arm that will rotate 15 degrees in either direction

- Hydraulic telescopic extending jib arm.

- Please see the Images Tab above for pictures of these features.

Features

- Allows operator freedom to work close to machines or over obstructions

- Designed with safety in mind, this crane meets all international safety standards

- Robust construction

- Manufactured from steel box section for combined strength and lightness

- All welded construction

- All models feature a heavy-duty, double-acting pump for fast action

- Fitted with a safety relief valve to prevent overload

- Top quality hydraulics fitted with chrome-plated piston rod on ram and pump

- Precision-built hydraulic ram

- Precision-built hydraulic pump

- Fitted with hard-wearing polyurethane front wheels and a swivel castor on the rear for easy movement of the crane when operational

- Rear swivel castors have brakes fitted

- Heavy-duty swivel hook fitted with a safety latch

- Each crane has been individually tested to 25% overload as a complete unit

- Test certificate/letter of conformity supplied with each crane

- Counterbalance not supplied, if ballast less than the stated amount is used, the safe working load will be reduced.

- Sand or concrete blocks can be used on 152kg, 254kg and 508kg

- Models 750kg and 1000kg require Metal Ballast

- Come with a 12-month guarantee

Standard Counterbalanced Crane

Stainless Steel Construction with Powered Hydraulics

Important Safety Information.

- Always inspect the hook and latch before using.

- Never use a latch that is distorted or bent.

- Always make sure the spring will force the latch against the tip of the hook

- Always make sure the hook supports the loads.

- The latch must never support the load

- When placing two or more loads may disengage from hook if proper procedures are not followed

- A falling load may cause serious injury or death

- A hook and this style latch must not be used for lifting personnel

- Hooks must always support the load

For Optional Features and Accessories - refer to the tab above "Optional Features"

Floor Cranes With Spark Resistant Features / Explosion Proof.

For Floor cranes to be used in potentially explosive areas/atmospheres such as Zone 1 or 2, SELS can include any anti-sparking features that our customers specify - this will increase its anti-sparking properties and therefore make the crane more suitable for use in a potentially explosive environment.

SELS will not take the responsibility of supplying our floor cranes described as 'spark proof' as this is ‘too broad’ a term. We believe that total compliance is probably impossible because of the mechanical operation and movement of a floor crane; i.e. we cannot offer a 100% guarantee that no part of the assembly is capable of generating a spark which could ignite a flame. IE: SELS will supply/manufacture cranes with anti-sparking features to our customers’ requirements, though will not certify them as sparkproof / explosion proof. Our cranes have been successfully supplied to customers in the offshore Oil and Gas industry in the UK on this basis.

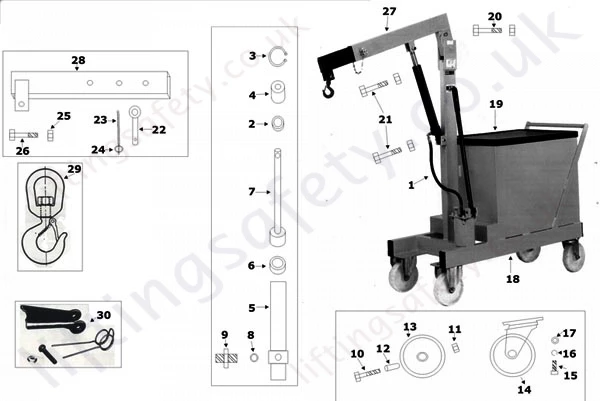

Spare Parts list for Counter Balance Cranes

| Part Number | Description | Quantity |

| 01 | Hydraulic Hose | 1 |

| 02 | Scraper Ring | 1 |

| 03 | Cir-Clip | 1 |

| 04 | Guide Bush | 1 |

| 05 | Hydraulic Cylinder | 1 |

| 06 | Piston Seal | 1 |

| 07 | Piston Rod | 1 |

| 08 | Dowty Seal | 1 |

| 09 | Hydraulic Fitting | 1 |

| 10 | Wheel Bolt | 1 |

| 11 | Nut | 1 |

| 12 | Wheel Bush | 4 |

| 13 | Wheel | 4 |

| 14 | Swivel Castor Complete | 2 |

| 14A | Fixed Castor Complete | 2 |

| 15 | Set Screw | 16 |

| 16 | Spring Washer | 16 |

| 17 | Plain Washer | 16 |

| 18 | Main Frame | 1 |

| 19 | Ballast Box Lid | 1 |

| 20 | Jib/Column Nut and Bolt | 1 |

| 21 | Ram Nut and Bolt | 2 |

| 22 | Jib Pin | 1 |

| 23 | Jib Pin Chain | 1 |

| 24 | Lynch Pin | 1 |

| 25 | Hook Nut | 1 |

| 26 | Hook Bolt | 1 |

| 27 | Jib | 1 |

| 28 | Jib Extension | 1 |

| 29 | Hook | 1 |

| 30 | Hook Safety Latch | 1 |

Specialist Crane: Food, Offshore and Pharmaceutical Industry Stainless Steel Counter Balance Workshop Floor Crane.

Selby Engineering and Lifting Safety Ltd can offer innovative lifting solutions to suit your environment and lifting needs.

This is our stainless steel counter balance floor crane that can incorporate all of the features of any crane in our range of counterbalanced floor cranes designed to be used in corrosive environments and to be suitable for customers working in specialist environments, such as the pharmaceutical or food industries, where exacting standards must be satisfied.

This stainless steel counter weight floor crane can also features electric powered lift and powered travel if required.

The picture shown represents our standard range of manually maneuvered counterbalance stainless steel floor cranes, this crane is 125kg SWL though we offer 6 standard cranes with safe working loads up to 2000kg.We make these items as bespoke orders and can generally adapt to the individual requirements of the customer.

Features

- Allows operator freedom to work close up to and over obstructions

- Stainless steel cranes meets all international safety standards

- Robust construction, made to last

- Manufactured from hollow steel box section for combined strength and lightness

- All Welded construction, to seam stitched as with other less robust alternatives

- All models feature a heavy duty, double-acting pump for fast action and are fitted with a safety relief valve to prevent overload. These are top quality hydraulics fitted with chrome plated piston rod on ram and pump; a Precision built hydraulic ram and hand pump

- Supplied with hard wearing polyurethane front wheels and swivel Castor's on the rear for easy movement of the crane when operational and rear swivel castors have brakes fitted

- Heavy duty swivel hook fitted with safety latch and every crane has been individually tested to 125% of SWL and supplied with a test certificate and CE certificate of conformity

- Counterbalance can be supplied as mild steel or as stainless steel

- Come with a 12 month guarantee.

Optional Features and Accessories

Listed below are some additional features that can be added to any of our standard range of counterbalance floors cranes to customise the them so that they will be more appropriate for your environment. All these features can also be supplied with our stainless steel cranes.

Awaiting Image

User Instructions

Complete user instructions for the model of counter-balance floor crane.

(approx. 5.6Mb)Safety Instructions

General safety instructions for the safe use of floor cranes.

(approx. 0.1Mb)Dimensional Drawings

Full dimensional drawings for this counter balanced floor crane.

(approx. 1.3Mb)1500kg Dimensions

(approx. 0.1Mb)Weights and Dimensions

(approx. 0.1Mb)This is our most popular counterbalance workshop floor crane, and the design of this portable floor crane incorporates many key features that make it one of the most versatile items of workshop lifting equipment that we sell. We also make special versions of the crane to our customers' own specification with bespoke dimensions and lifting capacities, jib reach and height.

Note: Some pictures shown are our artists' impression only and are only indicative of our capability. (for display purposes only) All cranes are made individually, and the design may be subject to change according to your required specification; the pictures are not to scale. General arrangement drawings will be issued for approval on receipt of your order.

The most common additions to the standard cranes are:

- Removable vertical jib column to assist packing for export orders

- Vertical telescopic mast adjustment

- Brakes with locking castors and directional locking castors/wheels

- Electric power drive/propulsion and electric lift

- Outriggers on the crane body ensure a stable lift at height.

- Certified lifting points for the ability to have a crane lifted/moved by an overhead crane.

- Fork truck pockets, to enable the counterbalanced floor crane to be moved by a fork truck.

- Jacking feet to give a level and stable lift

- A rotating vertical jib arm that will rotate 15 degrees in either direction

- Hydraulic telescopic extending jib arm.

- Please see the Images Tab above for pictures of these features.

Features

- Allows operator freedom to work close to machines or over obstructions

- Designed with safety in mind, this crane meets all international safety standards

- Robust construction

- Manufactured from steel box section for combined strength and lightness

- All welded construction

- All models feature a heavy-duty, double-acting pump for fast action

- Fitted with a safety relief valve to prevent overload

- Top quality hydraulics fitted with chrome-plated piston rod on ram and pump

- Precision-built hydraulic ram

- Precision-built hydraulic pump

- Fitted with hard-wearing polyurethane front wheels and a swivel castor on the rear for easy movement of the crane when operational

- Rear swivel castors have brakes fitted

- Heavy-duty swivel hook fitted with a safety latch

- Each crane has been individually tested to 25% overload as a complete unit

- Test certificate/letter of conformity supplied with each crane

- Counterbalance not supplied, if ballast less than the stated amount is used, the safe working load will be reduced.

- Sand or concrete blocks can be used on 152kg, 254kg and 508kg

- Models 750kg and 1000kg require Metal Ballast

- Come with a 12-month guarantee

Standard Counterbalanced Crane

Stainless Steel Construction with Powered Hydraulics

Important Safety Information.

- Always inspect the hook and latch before using.

- Never use a latch that is distorted or bent.

- Always make sure the spring will force the latch against the tip of the hook

- Always make sure the hook supports the loads.

- The latch must never support the load

- When placing two or more loads may disengage from hook if proper procedures are not followed

- A falling load may cause serious injury or death

- A hook and this style latch must not be used for lifting personnel

- Hooks must always support the load

For Optional Features and Accessories - refer to the tab above "Optional Features"

Floor Cranes With Spark Resistant Features / Explosion Proof.

For Floor cranes to be used in potentially explosive areas/atmospheres such as Zone 1 or 2, SELS can include any anti-sparking features that our customers specify - this will increase its anti-sparking properties and therefore make the crane more suitable for use in a potentially explosive environment.

SELS will not take the responsibility of supplying our floor cranes described as 'spark proof' as this is ‘too broad’ a term. We believe that total compliance is probably impossible because of the mechanical operation and movement of a floor crane; i.e. we cannot offer a 100% guarantee that no part of the assembly is capable of generating a spark which could ignite a flame. IE: SELS will supply/manufacture cranes with anti-sparking features to our customers’ requirements, though will not certify them as sparkproof / explosion proof. Our cranes have been successfully supplied to customers in the offshore Oil and Gas industry in the UK on this basis.

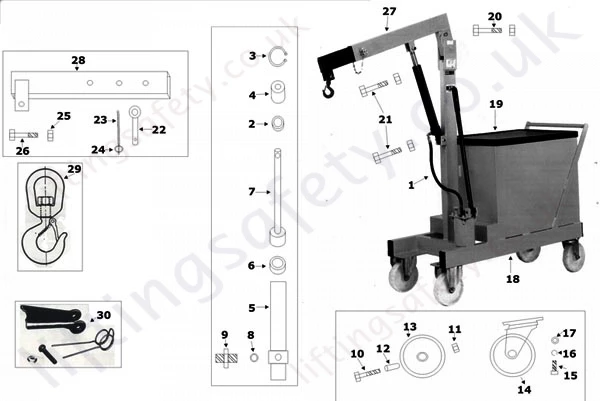

Spare Parts list for Counter Balance Cranes

| Part Number | Description | Quantity |

| 01 | Hydraulic Hose | 1 |

| 02 | Scraper Ring | 1 |

| 03 | Cir-Clip | 1 |

| 04 | Guide Bush | 1 |

| 05 | Hydraulic Cylinder | 1 |

| 06 | Piston Seal | 1 |

| 07 | Piston Rod | 1 |

| 08 | Dowty Seal | 1 |

| 09 | Hydraulic Fitting | 1 |

| 10 | Wheel Bolt | 1 |

| 11 | Nut | 1 |

| 12 | Wheel Bush | 4 |

| 13 | Wheel | 4 |

| 14 | Swivel Castor Complete | 2 |

| 14A | Fixed Castor Complete | 2 |

| 15 | Set Screw | 16 |

| 16 | Spring Washer | 16 |

| 17 | Plain Washer | 16 |

| 18 | Main Frame | 1 |

| 19 | Ballast Box Lid | 1 |

| 20 | Jib/Column Nut and Bolt | 1 |

| 21 | Ram Nut and Bolt | 2 |

| 22 | Jib Pin | 1 |

| 23 | Jib Pin Chain | 1 |

| 24 | Lynch Pin | 1 |

| 25 | Hook Nut | 1 |

| 26 | Hook Bolt | 1 |

| 27 | Jib | 1 |

| 28 | Jib Extension | 1 |

| 29 | Hook | 1 |

| 30 | Hook Safety Latch | 1 |

Specialist Crane: Food, Offshore and Pharmaceutical Industry Stainless Steel Counter Balance Workshop Floor Crane.

Selby Engineering and Lifting Safety Ltd can offer innovative lifting solutions to suit your environment and lifting needs.

This is our stainless steel counter balance floor crane that can incorporate all of the features of any crane in our range of counterbalanced floor cranes designed to be used in corrosive environments and to be suitable for customers working in specialist environments, such as the pharmaceutical or food industries, where exacting standards must be satisfied.

This stainless steel counter weight floor crane can also features electric powered lift and powered travel if required.

The picture shown represents our standard range of manually maneuvered counterbalance stainless steel floor cranes, this crane is 125kg SWL though we offer 6 standard cranes with safe working loads up to 2000kg.We make these items as bespoke orders and can generally adapt to the individual requirements of the customer.

Features

- Allows operator freedom to work close up to and over obstructions

- Stainless steel cranes meets all international safety standards

- Robust construction, made to last

- Manufactured from hollow steel box section for combined strength and lightness

- All Welded construction, to seam stitched as with other less robust alternatives

- All models feature a heavy duty, double-acting pump for fast action and are fitted with a safety relief valve to prevent overload. These are top quality hydraulics fitted with chrome plated piston rod on ram and pump; a Precision built hydraulic ram and hand pump

- Supplied with hard wearing polyurethane front wheels and swivel Castor's on the rear for easy movement of the crane when operational and rear swivel castors have brakes fitted

- Heavy duty swivel hook fitted with safety latch and every crane has been individually tested to 125% of SWL and supplied with a test certificate and CE certificate of conformity

- Counterbalance can be supplied as mild steel or as stainless steel

- Come with a 12 month guarantee.

Optional Features and Accessories

Listed below are some additional features that can be added to any of our standard range of counterbalance floors cranes to customise the them so that they will be more appropriate for your environment. All these features can also be supplied with our stainless steel cranes.

Awaiting Image

User Instructions

Complete user instructions for the model of counter-balance floor crane.

(approx. 5.6Mb)Safety Instructions

General safety instructions for the safe use of floor cranes.

(approx. 0.1Mb)Dimensional Drawings

Full dimensional drawings for this counter balanced floor crane.

(approx. 1.3Mb)1500kg Dimensions

(approx. 0.1Mb)Weights and Dimensions

(approx. 0.1Mb)You May Also Like

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.

Share this page!