- Lifting Equipment

-

Height Safety

Height Safety Equipment

- Material Handling & Jacking Equipment

- Shop by Brand

- Clearance

-

Contact

Get In Touchsales@liftingsafety.co.uk +44 (0)1977 684 600

- Home/

- Lifting Equipment/

- Chain Hoists/

- Air Hoists/

- Yale Air Hoists/

- Yale CPA Atex Air Hoist

The conception is in accordance with the design of the model CPE. With 100 % duty rating and an unlimited number of starts the model CPA is suitable for heavy duty applications. It is insusceptible to contamination, humidity and aggressive mediums from the outside. The hoists are composed of three main components which makes service easy and inexpensive.

Features

- Robust rotating piston has an adjustable spring pressure brake that holds the load secure even in the event of an air failure

- High starting torque due to switching valves in the motor body

- Sensitive starting torque due to switching valves in the motor body

- Sensitive control by means of 2 resp. 4 button pendent control with emergency stop.

- Low noise emission due to large dimension silencer

- Designed for operating pressure of 4 to 6 bar

- The standard, oil bath lubricated planetary gearbox is particularly smooth running and enables a low overall height

- the 5-pocket load chain sheave, manufactured from wear resistant case hardening steel, is matched perfectly to the load chain to guarantee smooth and precise motion.

- The assembly of components parts result in a low overall height (up to 3000 kg only one chain fall)

- The replacement chain guide is robust and precision machined

- Copper-plated suspension and load hooks

- The standard case hardened and zinc-plated link chain is matched perfectly to the load chain to guarantee smooth and precise chain motion. All requirements of national and international standards and regulations are fulfilled.

Technical data

| Capacity (kg) | Size | Beam flange width b (mm) | Beam flange thickness t max. (mm) | Curve radius min (m) | Pneumatic trolley travel speed (m/min) | Pneumatic trolley motor (kW) |

| 2000 - 6000 | A | 98 - 180 | 27 | 2.0 | 18 | 0.55 |

| 2000 - 6000 | B | 180 - 300 | 27 | 1.8 | 18 | 0.55 |

| 7500 - 10000 | B | 125 - 310 | 40 | 1.8 | - | - |

Yale ATEX Levels of Protection

All of Yale’s ATEX hoists meet the following standards: EN1127-1:1997; EN13463-1:2001; EN13463-5:2003, and are supplied complete with the relevant ATEX approval documentation.

Yale (Columbus McKinnon) offer three levels of protection - BASIC, MEDIUM, and HIGH.

Under directive 94/9/EC, equipment for areas with an explosion hazard are assigned to groups, categories and temperature classes. This is necessary as the requirements for equipment need not be the same for every application and for every hazard classification.

NB: It is the responsibility of the end user to identify the explosion proof classification required, NOT the hoist manufacturer or the supplier. Reference Directive 99/92/EC.

|

BASIC ATEX II 3 GD c IIB T4 (Zone 2/22) |

MEDIUM ATEX II 2 GD c IIB T4 (Zone 1/21 & 2/22) |

HIGH ATEX II 2 GD c IIC T4 (Zone 1/21 & 2/22) |

|

|

|

Why explosion protection?

Explosion protection for electrical and mechanical machinery is an important precautionary measure to ensure the safety of persons and all kinds of production, storage and distribution systems, when explosive mixtures of combustible gases, dusts and air may occur.

What does explosion protection achieve?

Explosion protection can mean to generally prevent the ignition of an explosive mixture. Explosion protection can also be achieved by eliminating potential ignition sources in advance, e.g. high temperatures and sparking. In many trades and industries, combustible gases, vapours and dusts are handled which have the potential to cause explosions.

Examples of explosion hazards in various industries

- Chemical industry

- Waste disposal sites

- Energy production companies

- Waste management companies

- Gas suppliers

- Metal processing companies

- Wood-processing companies

- Paint shops

- Agriculture

- Food and feed-stuffs industry

- Pharmaceutical industry

- Refineries

- Recycling companies

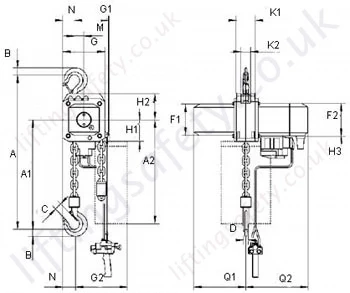

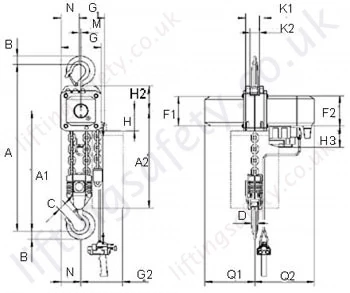

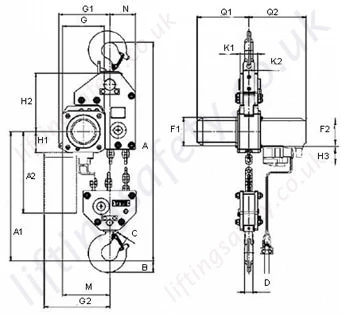

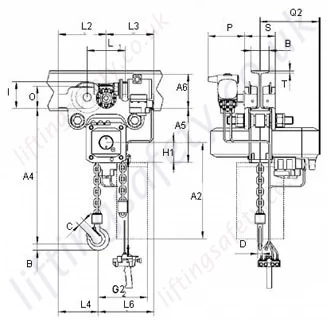

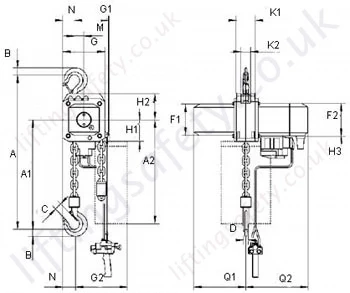

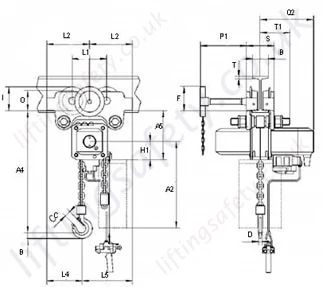

| Model | CPA ATEX 20-8 | CPA ATEX 30-6 | CPA ATEX 40-4 | CPA ATEX 50-3 | CPA ATEX 60-3 | CPA ATEX 75-2 | CPA ATEX 100-2 |

| A, (mm) | 516 | 516 | 681 | 681 | 681 | 950 | 1,068 |

| A1 (mm) | 286 | 286 | 428 | 428 | 428 | 479 | 651 |

| B (mm) | 35 | 35 | 45 | 47 | 47 | 60 | 60 |

| C (mm) | 37 | 37 | 46 | 42 | 42 | 52 | 52 |

| D (mm) | 24 | 24 | 30 | 30 | 30 | 40/45 | 40/45 |

| F1 (mm) | 160 | 160 | 160 | 160 | 160 | 160 | 160 |

| F2 (mm) | 165 | 165 | 165 | 165 | 165 | 165 | 165 |

| G (mm) | 220 | 220 | 220 | 220 | 220 | 220 | 581 |

| G1 (mm) | 180 | 180 | 140 | 140 | 140 | 268 | 311 |

| G2 (13 m) | 258 | 258 | 218 | 218 | 218 | - | - |

| G2 (21 m) | 278 | 278 | 238 | 238 | 238 | 345 | 408 |

| H1 (mm) | 110 | 110 | 110 | 110 | 110 | 110 | 110 |

| H2 (mm) | 135 | 135 | 135 | 135 | 135 | 307 | 256 |

| H3 (mm) | 115 | 115 | 115 | 115 | 115 | 115 | 115 |

| K1 (mm) | 100 | 100 | 100 | 100 | 100 | 92 | 92 |

| K2 (mm) | 51 | 51 | 51 | 51 | 51 | 62 | 62 |

| M (mm) | 50 | 50 | 9,6 | 9,6 | 9,6 | 139 | 181 |

| N (mm) | 60 | 60 | 100 | 100 | 100 | 136 | 291 |

| Q1 (mm) | 272 | 272 | 272 | 272 | 272 | 272 | 272 |

| Q2 (mm) | 325 | 325 | 325 | 325 | 325 | 325 | 325 |

| Model | CPA ATEX 20-8 | CPA ATEX 30-6 | CPA ATEX 40-4 | CPA ATEX 50-3 | CPA ATEX 60-3 | CPA ATEX 75-2 | CPA ATEX 100-2 |

| A2 (13m). (mm) | 430 | 430 | 430 | 430 | 430 | - | - |

| A2 (21m), (mm) | 530 | 530 | 530 | 530 | 530 | 530 | 530 |

| A4 (mm) | 465 | 465 | 615 | 615 | 615 | 855 | 965 |

| A5 (mm) | 298 | 298 | 298 | 298 | 298 | 477 | 425 |

| A6 (mm) | 190 | 190 | 190 | 190 | 190 | 182 | 182 |

| b (mm) | A = 98 - 180 | A = 98 - 180 | A = 98 - 180 | A = 98 - 180 | A = 98 - 180 | 125 - 310 | 125 - 310 |

| B = 180 - 300 | B = 180 - 300 | B = 180 - 300 | B = 180 - 300 | B = 180 - 300 | |||

| F (mm) | 150 | 150 | 150 | 150 | 150 | 113 | 113 |

| I (mm) | 142,5 | 142,5 | 142,5 | 142,5 | 142,5 | 130 | 130 |

| L1 (mm) | 209 | 209 | 209 | 209 | 209 | 200 | 200 |

| L2 (mm) | 262,5 | 262,5 | 262,5 | 262,5 | 262,5 | 215 | 215 |

| L3 (mm) | 265 | 265 | 265 | 265 | 265 | 265 | 265 |

| L4 (mm) | 213 | 213 | 253 | 253 | 253 | 291 | 291 |

| L5 (mm) | 312 | 312 | 272 | 272 | 272 | - | - |

| L6 (mm) | 315 | 315 | 275 | 275 | 275 | - | - |

| O (mm) | 125 | 125 | 125 | 125 | 125 | 150 | 150 |

| P (mm) | 208 | 208 | 208 | 208 | 208 | 208 | 208 |

| P1 (mm) | 284 | 284 | 284 | 284 | 284 | 284 | 284 |

| S (mm) | B + 70 | B + 70 | B + 70 | B + 70 | B + 70 | B + 98 | b + 98 |

| T (mm) | 27 | 27 | 27 | 27 | 27 | 40 | 40 |

| T1 size A | 182 | 182 | 182 | 182 | 182 | - | - |

| T1 size B | 242 | 242 | 242 | 242 | 242 | 270 | 270 |

Pricing

The conception is in accordance with the design of the model CPE. With 100 % duty rating and an unlimited number of starts the model CPA is suitable for heavy duty applications. It is insusceptible to contamination, humidity and aggressive mediums from the outside. The hoists are composed of three main components which makes service easy and inexpensive.

Features

- Robust rotating piston has an adjustable spring pressure brake that holds the load secure even in the event of an air failure

- High starting torque due to switching valves in the motor body

- Sensitive starting torque due to switching valves in the motor body

- Sensitive control by means of 2 resp. 4 button pendent control with emergency stop.

- Low noise emission due to large dimension silencer

- Designed for operating pressure of 4 to 6 bar

- The standard, oil bath lubricated planetary gearbox is particularly smooth running and enables a low overall height

- the 5-pocket load chain sheave, manufactured from wear resistant case hardening steel, is matched perfectly to the load chain to guarantee smooth and precise motion.

- The assembly of components parts result in a low overall height (up to 3000 kg only one chain fall)

- The replacement chain guide is robust and precision machined

- Copper-plated suspension and load hooks

- The standard case hardened and zinc-plated link chain is matched perfectly to the load chain to guarantee smooth and precise chain motion. All requirements of national and international standards and regulations are fulfilled.

Technical data

| Capacity (kg) | Size | Beam flange width b (mm) | Beam flange thickness t max. (mm) | Curve radius min (m) | Pneumatic trolley travel speed (m/min) | Pneumatic trolley motor (kW) |

| 2000 - 6000 | A | 98 - 180 | 27 | 2.0 | 18 | 0.55 |

| 2000 - 6000 | B | 180 - 300 | 27 | 1.8 | 18 | 0.55 |

| 7500 - 10000 | B | 125 - 310 | 40 | 1.8 | - | - |

Yale ATEX Levels of Protection

All of Yale’s ATEX hoists meet the following standards: EN1127-1:1997; EN13463-1:2001; EN13463-5:2003, and are supplied complete with the relevant ATEX approval documentation.

Yale (Columbus McKinnon) offer three levels of protection - BASIC, MEDIUM, and HIGH.

Under directive 94/9/EC, equipment for areas with an explosion hazard are assigned to groups, categories and temperature classes. This is necessary as the requirements for equipment need not be the same for every application and for every hazard classification.

NB: It is the responsibility of the end user to identify the explosion proof classification required, NOT the hoist manufacturer or the supplier. Reference Directive 99/92/EC.

|

BASIC ATEX II 3 GD c IIB T4 (Zone 2/22) |

MEDIUM ATEX II 2 GD c IIB T4 (Zone 1/21 & 2/22) |

HIGH ATEX II 2 GD c IIC T4 (Zone 1/21 & 2/22) |

|

|

|

Why explosion protection?

Explosion protection for electrical and mechanical machinery is an important precautionary measure to ensure the safety of persons and all kinds of production, storage and distribution systems, when explosive mixtures of combustible gases, dusts and air may occur.

What does explosion protection achieve?

Explosion protection can mean to generally prevent the ignition of an explosive mixture. Explosion protection can also be achieved by eliminating potential ignition sources in advance, e.g. high temperatures and sparking. In many trades and industries, combustible gases, vapours and dusts are handled which have the potential to cause explosions.

Examples of explosion hazards in various industries

- Chemical industry

- Waste disposal sites

- Energy production companies

- Waste management companies

- Gas suppliers

- Metal processing companies

- Wood-processing companies

- Paint shops

- Agriculture

- Food and feed-stuffs industry

- Pharmaceutical industry

- Refineries

- Recycling companies

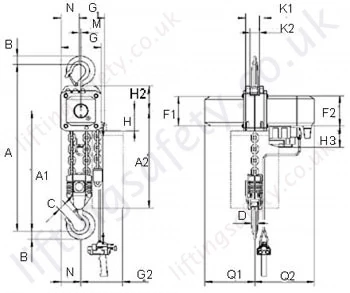

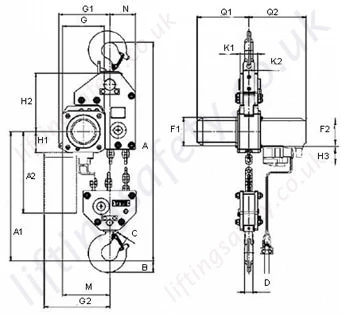

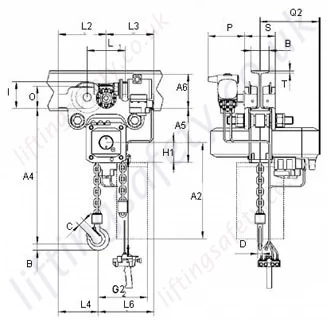

| Model | CPA ATEX 20-8 | CPA ATEX 30-6 | CPA ATEX 40-4 | CPA ATEX 50-3 | CPA ATEX 60-3 | CPA ATEX 75-2 | CPA ATEX 100-2 |

| A, (mm) | 516 | 516 | 681 | 681 | 681 | 950 | 1,068 |

| A1 (mm) | 286 | 286 | 428 | 428 | 428 | 479 | 651 |

| B (mm) | 35 | 35 | 45 | 47 | 47 | 60 | 60 |

| C (mm) | 37 | 37 | 46 | 42 | 42 | 52 | 52 |

| D (mm) | 24 | 24 | 30 | 30 | 30 | 40/45 | 40/45 |

| F1 (mm) | 160 | 160 | 160 | 160 | 160 | 160 | 160 |

| F2 (mm) | 165 | 165 | 165 | 165 | 165 | 165 | 165 |

| G (mm) | 220 | 220 | 220 | 220 | 220 | 220 | 581 |

| G1 (mm) | 180 | 180 | 140 | 140 | 140 | 268 | 311 |

| G2 (13 m) | 258 | 258 | 218 | 218 | 218 | - | - |

| G2 (21 m) | 278 | 278 | 238 | 238 | 238 | 345 | 408 |

| H1 (mm) | 110 | 110 | 110 | 110 | 110 | 110 | 110 |

| H2 (mm) | 135 | 135 | 135 | 135 | 135 | 307 | 256 |

| H3 (mm) | 115 | 115 | 115 | 115 | 115 | 115 | 115 |

| K1 (mm) | 100 | 100 | 100 | 100 | 100 | 92 | 92 |

| K2 (mm) | 51 | 51 | 51 | 51 | 51 | 62 | 62 |

| M (mm) | 50 | 50 | 9,6 | 9,6 | 9,6 | 139 | 181 |

| N (mm) | 60 | 60 | 100 | 100 | 100 | 136 | 291 |

| Q1 (mm) | 272 | 272 | 272 | 272 | 272 | 272 | 272 |

| Q2 (mm) | 325 | 325 | 325 | 325 | 325 | 325 | 325 |

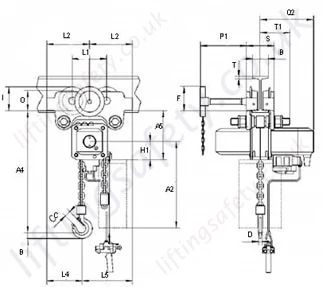

| Model | CPA ATEX 20-8 | CPA ATEX 30-6 | CPA ATEX 40-4 | CPA ATEX 50-3 | CPA ATEX 60-3 | CPA ATEX 75-2 | CPA ATEX 100-2 |

| A2 (13m). (mm) | 430 | 430 | 430 | 430 | 430 | - | - |

| A2 (21m), (mm) | 530 | 530 | 530 | 530 | 530 | 530 | 530 |

| A4 (mm) | 465 | 465 | 615 | 615 | 615 | 855 | 965 |

| A5 (mm) | 298 | 298 | 298 | 298 | 298 | 477 | 425 |

| A6 (mm) | 190 | 190 | 190 | 190 | 190 | 182 | 182 |

| b (mm) | A = 98 - 180 | A = 98 - 180 | A = 98 - 180 | A = 98 - 180 | A = 98 - 180 | 125 - 310 | 125 - 310 |

| B = 180 - 300 | B = 180 - 300 | B = 180 - 300 | B = 180 - 300 | B = 180 - 300 | |||

| F (mm) | 150 | 150 | 150 | 150 | 150 | 113 | 113 |

| I (mm) | 142,5 | 142,5 | 142,5 | 142,5 | 142,5 | 130 | 130 |

| L1 (mm) | 209 | 209 | 209 | 209 | 209 | 200 | 200 |

| L2 (mm) | 262,5 | 262,5 | 262,5 | 262,5 | 262,5 | 215 | 215 |

| L3 (mm) | 265 | 265 | 265 | 265 | 265 | 265 | 265 |

| L4 (mm) | 213 | 213 | 253 | 253 | 253 | 291 | 291 |

| L5 (mm) | 312 | 312 | 272 | 272 | 272 | - | - |

| L6 (mm) | 315 | 315 | 275 | 275 | 275 | - | - |

| O (mm) | 125 | 125 | 125 | 125 | 125 | 150 | 150 |

| P (mm) | 208 | 208 | 208 | 208 | 208 | 208 | 208 |

| P1 (mm) | 284 | 284 | 284 | 284 | 284 | 284 | 284 |

| S (mm) | B + 70 | B + 70 | B + 70 | B + 70 | B + 70 | B + 98 | b + 98 |

| T (mm) | 27 | 27 | 27 | 27 | 27 | 40 | 40 |

| T1 size A | 182 | 182 | 182 | 182 | 182 | - | - |

| T1 size B | 242 | 242 | 242 | 242 | 242 | 270 | 270 |

You May Also Like

Contact Us About This Product

If you wish to receive a quote for this product, please use the tab above, this form is for general enquiries regarding this product only.

You can also Request a Quote using the Quote tab above!

You can easily add more than one item to the Quote Request. This is highly recommended as we will be able to suit your needs much more efficiently.

Share this page!